AX defines our range of forage wagons that offer capacities from 25 m³ to 31 m³ and which are available with different extensions that give users the flexibility to use them as self-loading forage wagons with and without discharge rollers but also as silage trailers in the maize harvest chain. AX suggests maximum reliability, efficiency and flexibility.

- Camless pick-up for very quiet running and hard wearing

- Tines in W-arrangement for optimum crop flow

- Wide and large-diameter rotor for high intake rates

- Central blade group control system for 0, 16, 16, 32 blades

- Sloping floor enhances crop feed efficiencies

- Articulated drawbar for high ground clearance

- Drawbar suspension for comfortable rides

- Sprung or unsprung tandem axles with hydraulic levelling system

- ISOBUS compatible

Product video

KRONE AX – Self-loading and forager-filled forage wagons

AX defines our range of forage wagons that offer capacities from 25 m³ to 31 m³ and which are available with different extensions that give users the flexibility to use them as self-loading forage wagons with and without discharge rollers but also as silage trailers in the maize harvest chain. AX suggests maximum reliability, efficiency and flexibility.

Product features

The AX 310 as the flagship of the range offers a capacity of 31m³. It has a rugged steel extensions as standard specification or silage extensions as an option. The AX 310 D is the model that features either two or three discharge rollers at the rear. The 1,800 mm wide pick-up feeds the material to the rotor cutter with 32 blades that chops the material in scissor-like cuts to 45 mm lengths.

Offering a volume of 28 m³, the AX 280 self-loading forage wagon with discharge rollers is the most versatile machine in the AX range and can be specified with many different extensions – collapsible hay extensions, steel extensions or silage extensions. The AX 280 D model is specified with either two or three discharge rollers. The 1,800 mm wide pick-up feeds the material to the rotor cutter with 32 blades that chop the material in scissor-like cuts to 45 mm lengths.

Offering a volume of 25 m³, the AX 250 self-loading forage wagons with discharge rollers is the most compact model in the AX range and is available with collapsible or steel extensions. The AX 250 D is the model that also has discharge rollers at the rear. The camless and 1,800 mm wide pick-up gathers the material effectively and feeds it to the rotor cutter which in turn lines up 32 blades that cut the material to 45 mm chops at a minimum tractor input.

Silage extensions (HL / HD): The AX 280 and 310 can be specified with optional silage extensions. These include a silage hatch at the top of the headboard. Operated hydraulically, this flap moves forward for filling from the forager ahead. Without top ropes, the AX suits not only applications in which the material is collected by the pick-up but also when the wagon is filled by the forage harvester.

Steel extensions (GL / GD): All AX forage wagons are available with the extra strong steel extensions. The crop is secured with top ropes that ensure nothing is lost during transport. The steel tailboard is operated automatically by two single-acting rams

Collapsible hay extensions (FL / FD): The AX 250 L/D model has hay extensions that collapse hydraulically. With the extensions down, the machine easily passes under low gates. The top ropes, the slide cover in the front section and the rear cover ensure no material is lost in transport.

We off er the correct tyres for every harvest condition. Flotation tyres off er a larger contact area and are therefore preferable in boggy terrain as they reduce compaction and make for lighter pulling.

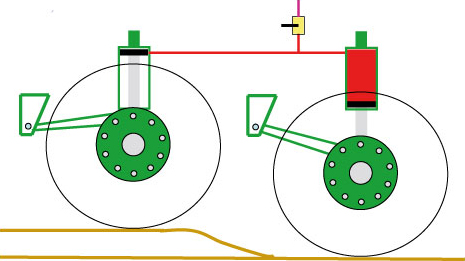

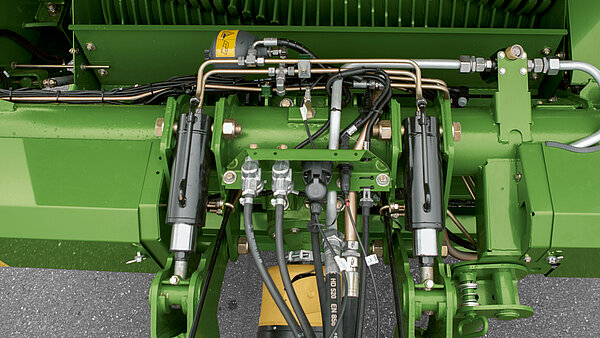

Great stability: The caster-steer axle assembly with hydraulic auto-levelling has two separate hydraulic circuits. The system reduces the risk of machine roll when working in sloping fi elds or travelling through bends. The AX manages undulations with ease as the oil fl ows from the cylinder on the front axle to the cylinder on the rear axle and vice versa to compensate for roll. This way the machine weight is uniformly distributed to all wheels as the machine is entering the clamp.

Running on comfort: The AX 250 has standard tandem axles with mechanical suspension that off er a gross axle load of 10 t, 14 t or 16 t depending on tyre size. The axle load on the AX 280 and 310 is 16 t and maximum speed is 40 km/h. One of the two rigid axles can be caster-steered as an option, which helps avoiding turf damage when travelling through bends. The steering can be locked during shunting and clamping.

A suspended drawbar is available as an option on the AX and is a particular boon during long-distance travel on bumpy roads.

The articulated drawbar offers hydraulic height control which can also be operated from an optional button on the headboard. The optional auto control feature allows operators to retrieve the stored field/road position of the drawbar easily and fast. The latter increases the ground clearance by up to 60 cm for easier manoeuvring on the headland or clamp.

Hitch ring: The top-mount 40 mm hitch ring couples to the tractor clevis.

Ball hitch: The bottom-mount ball hitch 80 brings great agility, minimizes wear and offers tongue loads of up to 3 tonnes.

The diameter of 6.5 cm and the large coils make the double tines particularly resilient and wear-resistant. Arranged in a wavy pattern, six rows of tines feed the material from the ends to the middle of the rotor, thereby preventing crop from building up as the machine travels through bends, for example, and spreading it evenly across the full width of the cutting rotor.

The crop press roller unit has a chain that allows operators to easily adjust the work height to ensure a uniform and consistent crop flow in varying crops, swath volumes and at varying ground speeds.

You can order two optional gauge wheels to run at the rear and outside the tractor wheelings to optimize contouring and minimize contamination in very difficult conditions.

Working at a width of 1.8 m (to DIN 11220), the pick-up gathers wide swaths no problem and feeds the material to the rotor cutter in a very consistent flow. Excellent ground contour following comes from the pivoting suspension and the leading gauge wheels that pivot sideways and also offer height control without tools.

After the blade cassette moves back into its working position, it locks home automatically on the right machine side.

After the cassette is released, it easily pulls out and swings alongside the machine for easy blades removal and replacement.

After the blade cassette lowers and the blades are withdrawn to ‘0’ position, operate a lever on the left side of the machine to remove the blade cassette.

When all 32 blades are set to cutting action, the system achieves a nominal chop length of 45 mm. The blade group control system allows operators to select the blades in sets of 32, 16, 16, 0.

Their wavy edges make precise and smooth cuts. The blade itself is plain and simple and the cutting edge is hardened twice. This is the KRONE formula for reduced wear and lasting sharpness – and the perfect combination for making long and challenging harvest days a success.

Measuring 760 mm in diameter and offering a working width of 1.47 m, the cutting rotor was developed for filling a high-capacity wagon. Its tines are arranged in six helical rows and have 25 mm Hardox plates for long service life. The scraper elements, too, are made from hard-wearing Hardox steel. The design ensures the tines feed the crop dependably through the blades for precise and scissor-like cuts and fast and uniform fills.

The AX models can be fitted with two or three discharge rollers. These have tines that are arranged in a V-line to distribute the material uniformly either on the clamp or in the feed passage. The bottom rotor revolves at a higher speed to boost unloading efficiency and crop flow consistency.

The AX loading and forage transport wagons discharge their load fast and dependably. The AX 250 has two chains and the AX 280 and 310 have four chains, which are made up of short 10 mm round-steel and high-tensile links. The scraper conveyor speed is controlled steplessly by a hydromotor. The models with discharge rollers have a reversing mechanism that moves the material away from the discharge rollers to remove a malfunction, for example.

The chain-and-slat floor slopes 100 mm at the front, which reduces the length of the feed channel and thus the amount of power required to feed the material into the load area, enabling a faster and gentler crop feed.

The optional cross conveyor belt is an ideal feature for farmers who feed the fresh forage directly to their cows. The 70 cm wide belt feeds the material to the right and left side. But you can also empty the machine as usual via the discharge rollers without any previous modification. The belt is integrated in the “rucksack” tailgate and moves out of the way when this is opened.

The forage wagon is a heavy-duty machine thanks to its channel- steel frame. The hot-galvanized and powder and plastic coated sides are high-quality and extremely durable. The sloping mudguards avoid crop collecting here.

The AX forage wagons that are fitted with discharge rollers have a large nearside door that gives convenient access to the load area after you climb the folddown ladder for a safe ascent.

The scraper conveyor speed of the PowerLoad is controlled automatically and adjusts itself relative to the load level of the precompression sensor. This helps distribute the load evenly in the loading and forage transport wagon and preserve the best possible feed quality. The target values can be set via the tractor's operating terminal.

This optional system activates and controls the chain-and-slat floor with the help of sensors. One sensor measures the pressure that the material exerts on the headboard (left photo). Another sensor at the top of the headboard scans the current angle of the silage hatch (right photo). The chain-and-slat floor is started automatically as soon as a the pressure scanned equals the set pressure. Depending on the crop, it is also possible to use the two sensors independently of each other.

When the machine is filled to capacity and material is pushing the bottom rotor to the rear, a motion detector stops the chains so the rollers can start off smoothly.

The tailgate on the wagons without discharge rollers has a sensor which stops the chains the moment it senses the machine is filled to capacity, thereby avoiding damage to the tailgate.

SmartConnect Solar enables you to connect machines in real time. The self-sufficient telemetry unit automatically records the location, route and operating hours independently of the manufacturer and completely autonomously thanks to the solar panel and rechargeable battery. On transport vehicles, the number of loads can also be recorded by mounting it on the tailgate. All of the relevant data is thus available for transparent and fair invoicing – perfect for leasing or service companies.

This is the base specification level for the AX loading and forage transport wagon – the Medium on-board electronic system complete with the Alpha control unit. which operates the pick-up, the articulated drawbar, the scraper conveyor and the tailgate.

The two operator terminals CCI 800 and 1200 with 8″ or 12″touch display allow users to split the screen. For example to see all machine control elements in one view and the camera footage in the other. Also, an additional AUX joystick enhances operator comfort even further.

The compact DS 500 terminal has a 5.7" colour display. can be operated with 12 function keys, the touchscreen or the scroll wheel on the back. An optional joystick is available for even more convenient operation.

The right model for every field of use

| AX 250 FL | AX 250 FD | AX 250 GL | AX 250 GD | AX 280 FL | AX 280 GL | AX 280 GD | AX 310 GL | AX 310 GD | AX 310 HL | AX 310 HD | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | loading wagon | loading wagon | loading wagon | loading wagon | loading and forage wagon | loading and forage wagon | loading and forage wagon | loading and forage wagon | loading and forage wagon | loading and forage wagon | loading and forage wagon |

configure

|

| Capacity (m³) | 25 | 25 | 25 | 25 | 28 | 28 | 28 | 31 | 31 | 31 | 31 |

configure

|

| Pick-up working width (m) | 1.80 | 1.80 | 1.80 | 1.80 | 1.80 | 1.80 | 1.80 | 1.80 | 1.80 | 1.80 | 1.80 |

configure

|

| Cutting length (mm) with 32 blades | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

configure

|

| No. of discharge rollers | none | 2 / 3 | none | 2 / 3 | none | none | 2 / 3 | none | 2 / 3 | none | 2 / 3 |

configure

|

| Power requirement kW/hp | 59 / 80 | 59 / 80 | 59 / 81 | 59 / 82 | 66 / 90 | 66 / 91 | 66 / 90 | 74 / 100 | 74 / 100 | 74 / 100 | 74 / 100 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)