KRONEGX:The all-rounder in the KRONE transport fleet hauls all kinds of crop and cargo.

Farming is about logistics and flexibility is key for the suc-cess of your business. As an all-round machine, the KRONE GX general-purpose wagon ticks exactly this box. Whether with a rigid (PLUS) or optional variable body (PRO), in which the side walls can be lowered by 660 mm all round – thanks to its unique concept, it can be used to transport almost all agricultural goods. The jack of all trades

- KRONE GX – jack of all trades. A machine for the whole year

- The unloading principle. A wall with a belt pulled by chains for the gentle transport of all types of goods

- The load area. Lightweight and robust, variable in height, variable in height on request

- KRONE single-piece frame. For low dead weight and high payload

- Operation. With PreSelect on the PLUS models or maximum conveni-ence on the PRO version thanks to ISOBUS and numerous automatic functions

- The underride guard. Hydraulically foldable for maximum comfort and safety

- The double-function tailgate. Smart folding and wide opening for maximum flexibility, even with discharge rollers

Product video

KRONE GX universal trailer – jack-of-all-trades for any type of agricultural cargo

GX stands for general-purpose wagon, the most recent addition to the Krone forage wagon range. This wagon offers a new level of versatility and gentle and fast unloading of a wide variety of cargo. The new machine is available in two sizes – 44 m³ and 52 m³ – with two optional discharge rollers. The GX 440 rides on tandem axles and the GX 520 on a tridem unit, with both models featuring standard Isobus operation.

Variantes

PLUS and PRO

New comfort designations for GX models from KRONE

To make it easier to differentiate between the GX machines, KRONE is intro-ducing new comfort designations. In future, the GX models will be available in the "PLUS" and "PRO" variants, each of which offers different operating options:

Product features

The GX doesn’t hibernate but continues earning its keep also in the winter months.

You can lower the extensions for easier loading and reduce the drop heights.

Operators appreciate the large inspection window when serving the forager.

The floor belt comes into its own in sensible crops like potatoes where it cushions the impact as the tubers drop into the machine.

The powerful floor drive empties the GX in no time so more time can be spent on compacting.

Unload grain conveniently and controlled through the standard- fit grain outlet, using the optional remote control.

The sealed body transports the smallest seeds without losses.

The articulated drawbar lowers the front end for easy filling from the forager.

Powerful discharge rollers unload the material in a wide and uniform mat.

The double-function tailgate and the reversible floor drive make a powerful formula for efficient loading and unloading.

The GX unloads any type of agricultural cargo fast and thoroughly.

The optional telescopic loading space extension simplifies loading with the wheeled loader and telehandler.

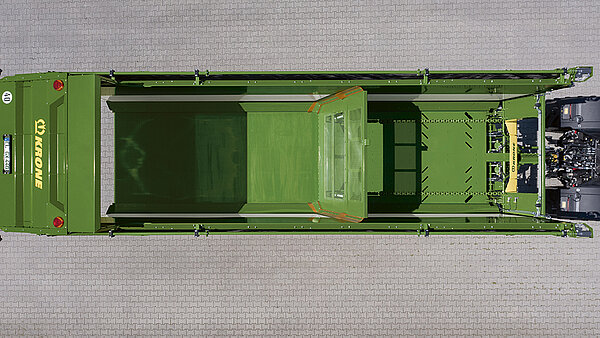

The headboard and moving floor form a powerful unit for gentle crop feeds

The massive flat-link chains that run under the floor are connected to the floor belt by a clamping strip and to the headboard by tightening springs. The materials used here are wear-resistant for uncompromised reliability and lifespan.

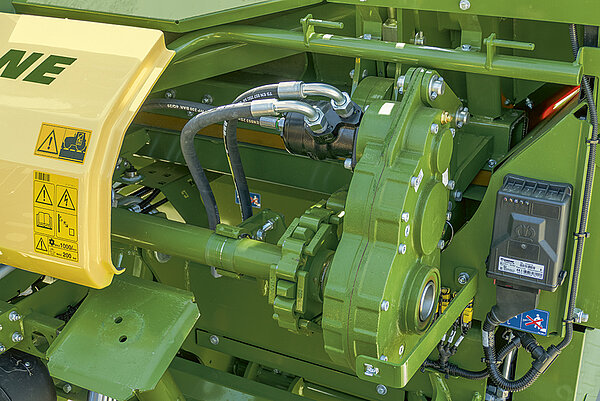

The unloading unit is driven by two powerful hydromotors and massive gearboxes with an equally massive shaft that synchronizes the drives. This unique system facilitates variable chain speeds and powerful unloading and loading.

The headboard and the floor belt form an integral unit which is pulled by two chains running underneath the floor, moving the material gently to the rear and unloading it without disrupting the texture of the silage heap. This unique concept unloads the material at a consistent rate. When the headboard finally reaches the rear end, the GX is completely emptied. The material is moving along conical sides with smooth surfaces for minimal friction.

As a general-purpose wagon, the GX is equally at home on the road and in the field. The running gear offers great ride comfort, good road stability and light running.

Use the remote control to operate the floor belt fore and aft when loading Big Bags, pallets or straw bales. The discharge rollers swing up and out of the way, allowing GX to take in any type of cargo for maximum versatility.

The GX also hauls solid manure and compost. You can lower the sides to reduce the filling height and improve operator visibility.

The GX is also an ideal trailer to haul any conceivable cash crops, especially crops that are sensitive to damage such as potatoes, beet and even vegetables. In the PRO version, the radio remote control enables controlled unloading of the rolling goods from the GX.

The GX general-purpose wagon transports all crops of all seed sizes whether coarse or fine – panicles, legumes and also oilseeds. Its grain outlet at the rear is a standard feature and allows operators to unload grain in a controlled way at the store.

The articulated and hydraulic drawbar plus the silage extensions make the GX the perfect trailer for serving the forage harvester – in silage maize, grass silage and whole crop silage. Typically KRONE, the general-purpose wagon is cleared out in no time so more time can be spent on compacting to make quality feed.

The articulated drawbar allows operators to alter the ground clearance hydraulically from the cab, which is a particular boon on the clamp. You can adjust the clearance flexibly and relative to steepness or slope gradient.

The standard-fit articulated drawbar comes into its own when the combination is following the forager, because it allows the trailer to ‘seesaw’ towards the tractor, presenting the load space to the forager chute for on-target filling.

The hydraulic drawbar suspension system gives comfy and convenient rides in all types of conditions, absorbing the shock loads instead of transferring them to the tractor. The GX stands for quiet and convenient tracking behind the tractor.

The overload height of the GX 440 and GX 520 PRO models can be variably adjusted on request. for convenient fillings and good operator visibility. Lowering the sides reduces the drop height by 660 mm – a boon when loading sensitive crops such as root crops.

The headboard has two large acrylic glass windows for inspecting the cargo space, offering a clear view into the machine for corrective steering and optimum filling from the forager.

Specially developed GRP sides are light-weight by design and held by massive stanchions, making a high-stability structure. This and the seals all-round make the GX the suitable trailer for hauling all types of agricultural cargo – from rape seeds to beets. The sloping mudguards ensure no debris collect here only to drop to the ground during road travel.

The KRONE GX is available in three ver-sions: GX 360 (36 m³), GX 440 (44 m³) and GX 520 (52 m³). These models offer versa-tile solutions – from compact to maximum efficiency for large transport tasks. True to the motto: the right vehicle for everyone. The large opening facilitates loading and minimises harvesting losses. The patented single-frame concept and lightweight construction guarantee an impressive payload.

You can attach the discharge rollers to the tailgate and swing them up and out of the way together with the gate for loading the machine conveniently from the rear. Alternatively, you can also remove the rollers in no time – a pragmatic design that offers maximum versatility.

KRONE GX boasts a very clever tailgate design. The discharge rollers can be attached to the sides or to the tailgate in a matter of seconds. No helper is required to refit the two bolts on either end of the rollers – a clever solution that speeds up changeovers.

The discharge rollers unload the material in a perfect mat. Measuring 440 mm in diameter and featuring aggressive tines, the two rollers take on huge masses of material and spread it in a uniform mat. This is the first step in a successful compacting and conservation process.

Up to 30.5" wheels Tyres are offered with a range of different treads and carcasses to provide the perfect outfit for every situation. There are 30.5" wheels for the GX 440 tan-dem axle version or for the GX 520 with the tridem axle version. for an increased footprint and reduced rolling resistance. 800/45 R 26.5 TL 174 D - 800/45 R 26.5 TL 174 D Trac - 710/50 R 30.5 TL 173 D universal profile - 800/45 R 30.5 TL 176 D Trac

The leading axle on the hydraulic tridem axles can be raised during an empty haul, which is done with the touch of a button, saving tyre wear and costs.

The two hydraulic cylinders on either side of the running gear share the same hydraulic circuit which distributes the oil and hence the load uniformly across all axles for quiet running, consistent tongue load and greatest stability.

The GX offers great ride stability on roads and in sloping fields. KRONE running gears impress with their unique axle joint and the associated quiet running behaviour. Stability is particularly important when working on slopes or clamping. Smoothing out rough rides, the hydraulic system allows the GX to float across the road.

Ever bigger and faster tractors, ever higher trailer capacities and payloads call for a thorough rethink on road and field safety. Therefore KRONE offers the electronic braking system as an option. Sourced from the industrial sector, the system has proven exceptionally well for many years. In addition, intelligent steered axles help protect the ground and provide added safety.

As a general-purpose wagon, the GX is designed to also operate in extreme conditions. Therefore the braking unit sits on top of the axle where it is protected from dirt for reliable operation and maximum ground clearance.

EBS is the optional electronic brake system, which comprises ALB, ABS and RSS functions. The roll stability system applies the brakes when it detects a risk of rollover, ensuring greatest stability when taking tight turns at speed. Combined, all these functions lead to an enhanced reliability

All GX models are equipped with a dual-line compressed air brake system as standard. The hydraulic ALB valve controls the braking power relative to the current load. Spring accumulated braking cylinders ensure the machine is parked up safely in any terrain.

The speciality of this steering system is a processor which receives data from a steering angle sensor and connecting rod. The integral hydraulic system supplies the steering cylinder with oil, making GX a very nimble machine. As forward speed increases, operator interference decreases for added road safety. Yet in field mode, the operators can interfere in the steering, which is important on the slope or clamp or when shunting, for example.

The steering system on tandem and tridem axle models is attached to the tractor via a standardised ball head, a steering rod and a hydraulic master cylinder which controls the oil flow to and from the steering cylinder.

The self-steering system is standard equipment on the GX 360 and GX 440 models with tandem unit. The steering system can be locked using locking cylinders during shunting, clamping and when driving on the road. This steering system is simple yet con-venient thanks to the automatic steering axle lock which is acti-vated at a preset speed or when reversing.

The hydraulic functions of the GX 360 and 440 PLUS models are preselected as standard via PreSelect Digital on the ISOBUS terminal and then operated using the tractor-side con-trol units. To increase comfort, the function preselection can also be programmed on the tractor's control lever. Alternatively, the Pre-Select DS 50 provides a separate preselection operation unit which can be used to preselect the hydraulic functions.

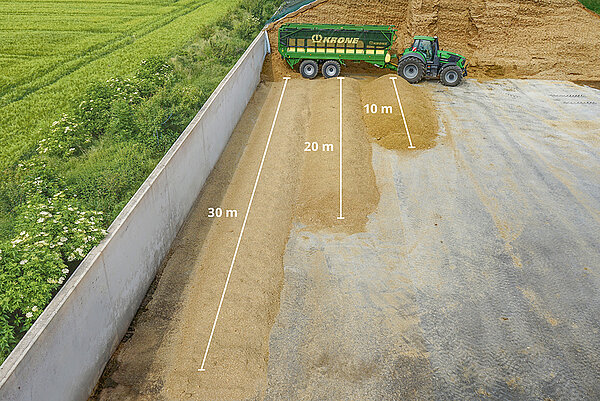

A world first – unique unloading control by length of the pit With ExactUnload, GX unloads its cargo automatically at rates that match the length of the pit. The operator sets the unloading rate infinitely variably for a course between 10 m and 100 m. ExactUnload controls the unloading rate actively to match the current forward speed of the tractor, helping you deliver the crop in accurate and reproduceable heaps. Laying out a nice blanket, the GX is particularly good at filling silage pits and controlled unloading routines in the field. ExactUnload is available as an option for the PLUS models and is integrated as standard for the PRO models.

The radio remote control on the GX 440 and 520 PRO models enables convenient loading and unloading from outside the cabin. It allows the tailgate to be opened and closed and the transport unit to be moved at different speeds. This means you always have the best overview and can work as efficiently as possible on your own.

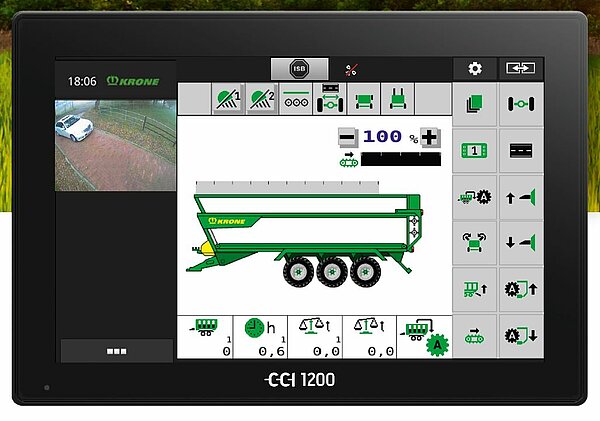

The standard ISOBUS operation of the GX PRO models enables convenient and clear control of the transport wagon. Its clear user interface offers intuitive operation and displays machine data and setup information. You can select your preferred view from configurable buttons. As it is our claim is to provide operators with an uncluttered and self-explanatory user interface and operator environment, the GX can be operated either from your tractor terminal or from an additional ISOBUS terminal – The CCI terminal family is particularly suitable for this, with which the machine and an optional rear-view camera can be displayed simultaneously via an 8 or 12-inch terminal.

LED rear lights complete with indicator lights, reverse and brake lights plus additional LED lights at the top warn motorists ahead of a turn. Sidelights indicate the full size of the machine.

KRONE transport wagons can optionally be fitted with a camera in the loading space and a rear-view camera. The high-resolution images increase the field of view, make it easier to work and increase safety levels especially when shunting, loading and unloading. Can be ideally combined with the CCI terminals or the 7" monitor – to ensure perfect control in every situation.

A hydraulic underride guard brings added safety on public roads. You can fold it up to make shunting alongside chasers and harvesters much easier. Besides, no crops can collect on the guard when it is out of the way. It folds automatically into road position as soon as the forward speed reaches 15 km/h.

Up to eight extra sidelights are available for the KRONE GX model as an option, illuminating the axle and the vicinity of the machine for safer and easier shunting and travel alongside the forager at night as well as for added safety on the clamp.

Crop covers are an option for the KRONE general-purpose wagons. They secure the crop in swift road transport. The covers open and close hydraulically.

The pressure gauges show the current payload by indicating the pressure inside the hydraulic cylinders on the articulated drawbar and in the running gear

The measurements of the optional electronic weighing device, which is available only on the PRO models, are taken via gauging pins on the drawbar and on the tandem or tridem unit with hydraulic compensation. The weight of the load is equivalent to the accumulated drawbar tongue load and axle load. The weight is recorded and evaluated by job and displayed on the display screen.

Optional LED light bars can be installed inside the load space for optimized visibility. Indirect lights make filling the machine from a harvester more pleasant. They can be operated together with the tractor lights.

The GX can be optionally equipped with the KRONE SmartConnect telemetry unit which forms the basis for modern data management with GPS and WLAN functions. This interface makes it easy to track the current location of the transport wagon and automatically records all important data which can be quickly transmitted to the office. On the PRO models, the Smart- Connect unit can be installed either as a KSC 500 or as a KSC Solar. The PLUS models can be equipped with the KSC Solar.

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)

![[Translate to EN:]](/fileadmin/_processed_/c/8/csm_IMG_8670_179105_9018c4043e.jpg)

![[Translate to EN:]](/fileadmin/_processed_/3/3/csm_DJI_20240829082417_0335_D_IS_258183_cb35796cbf.jpg)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm__AK13723_263521_63916ea1ac.jpg)