Mowing like a professional – the KRONE ActiveMow makes it possible at last. Perfect cutting quality ensures premium-quality forage, easy handling combined with compact and robust design guarantee maximum comfort and a long service life. The KRONE ActiveMow mower is the guarantor for successful forage harvesting.

- Robust and fully welded cutterbar without inner shoe

- SmartCut: Stripeless swath thanks to optimum blade overlaps

- Quick-change blades: Standard

- SafeCut: Impact protection for each individual disc

- Side-mounted mowers offering huge up/down travel

- Frictional drive via universal shafts and gearboxes

- Optimum ground pressure via tension springs adjustable without tools

- Compact in transport as the mower unit inclines to the middle of the tractor for optimum weight distribution and visibility

Product video

KRONE ActiveMow – Rear-mounted disc mowers

The KRONE ActiveMow mowers setting new benchmarks for lateral mowers. All ActiveMow models feature the same level of specification as the high-end KRONE mowers and the self-propelled high-capacity Big M, including a cutterbar with SmartCut effect, SafeCut cutterbar protection, a massive headstock and vertical storage as an option to minimise space requirement. The ActiveMow range lines up the following models: ActiveMow R 200 working at a 2.05m width, ActiveMow R 240 with a 2.44m work width, ActiveMow R 280 with 2.83m width, ActiveMow R 320 with a 3,22 m work width and ActiveMow R 360 working at 3,61m.

Product features

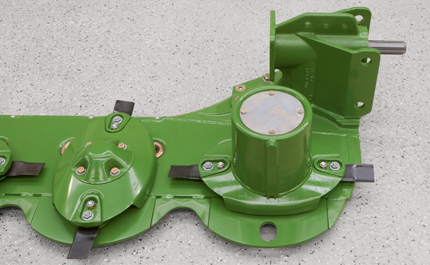

The all-round welded, enclosed cutterbar is maintenance-free and remains reliably sealed and dimensionally stable even after many years of use. Special cleaning processes during production enable lubrication for life and make the usual oil change superfluous.

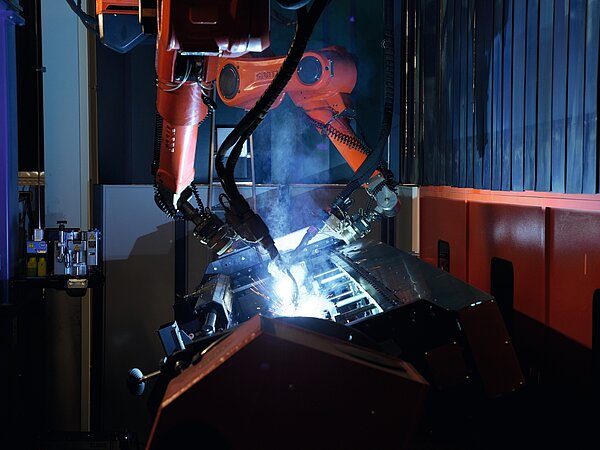

As the central element of every disc mower, the cutterbar is a particular focus at KRONE: Welded all round and lubricated for life, it is manufactured using the latest welding robot and CNC technology – for maximum precision, maximum durability and the highest quality standards.

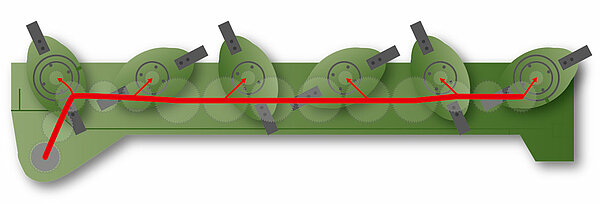

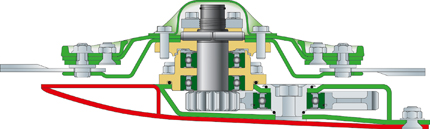

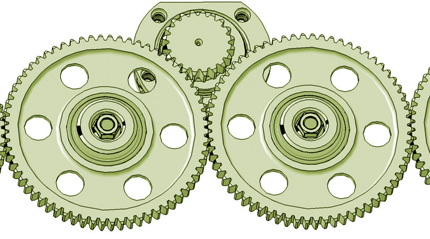

The established satellite drives were developed by KRONE and have proven extremely well all over the world for as many as 30 years now.Its massive spur gears with up to 59 teeth transmit the drive power down to the very last disc. The large-diameter gears rotate at reduced speeds, with a higher number of teeth meshing with the neighbouring gearwheels for even quieter running, ultimate efficiency and maximum longevity. The auxiliary gears drive one disc each and as a result are exposed to only minimum loading.

The cutterbar is driven by the right-angle gearbox just behind the inner top hat – for blockage-free operation on headlands and in awkward patches.

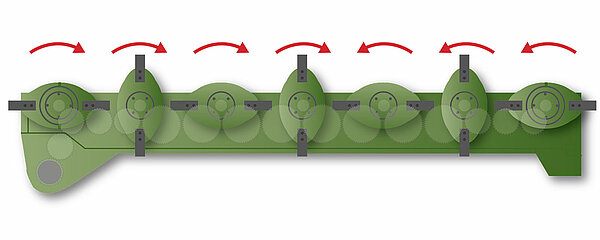

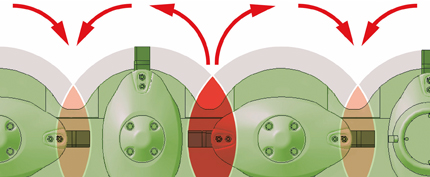

Spreading the material across the full machine width instead of swathing, it exposes a larger surface to the sun and wind for boosted and more uniform wilting.

With discs spinning in the B sense of rotation, ActiveMow spreads the material across the full cutting width. Here the discs turn in pairs towards each other.

Swathing is the preferred option in wet and boggy terrain so the tractor wheels will not run on the crop for loss-free pick-up or tedding.

The eccentric bearings are positioned in such a way that the discs feed the material to the middle of the machine for the tractor to straddle it. With discs spinning in the A sense of rotation, ActiveMow R 200, R 240, R 280 and R 320 form one single swath whereas the ActiveMow R 360 forms two swaths with its discs also spinning in the A sense of rotation.

We welded curved stops between the individual skids that protect the cutterbar from damage and also contoured the underside of the stops in such a way that no material can build up here and instead flows smoothly to the rear.

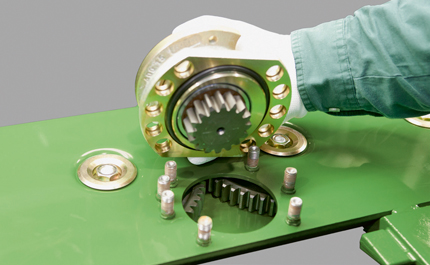

The spur gears are arranged in a forward position and eccentrically inside the gearbox right under the discs. The small auxiliary spur gears are removed from above, the massive main gears gearbox from the side.

The wedge-shaped cutterbar offers many height setting options. The spur gears run in massive double bearings, allowing the cutterbar to handle extremely high loads.

With some discs turning in pairs towards each other and others turning away from each other, it was necessary to redesign the degree of blade overlap to ensure cleanest cuts. For stripeless cuts in light and young crops, we have therefore increased blade overlaps on the discs turning outwards. In addition, the blades turning to the rear are set further apart to encourage a smooth flow of large volumes of crop.

Large-diameter spur gears with truncated teeth offer greater efficiency as a larger number of teeth is in mesh at any one time.

The blades are free to spin 360-deg. on their pins. They are hard-wearing and self-cleaning, well protected and will not foul with the blades on the neighbouring discs.

Worn blade fixing pins and wear parts are not an issue for KRONE ActiveMow, because the modular design of the cutting discs allows you to replace them individually. If you like, you can opt for bolts instead of pins.

112 mm long blades in a set shape and the wide overlap of the blade tracks ensure a clean cut and uniform forage flow.

The wide skids are fabricated from hardened boron steel to minimise the ground pressure and give enhanced contour following and cutterbar protection. The skids are bolted to the cutterbar so they are easy to replace.

Spare blades are neatly stored in this mobile drawer.

The curtain folds up for cleaning and replacing the blades – a compact design that offers superb accessibility.

Quick-change blades are considered a must by many farmers and contractors. The blades are quick and easy to reverse or replace in situ.

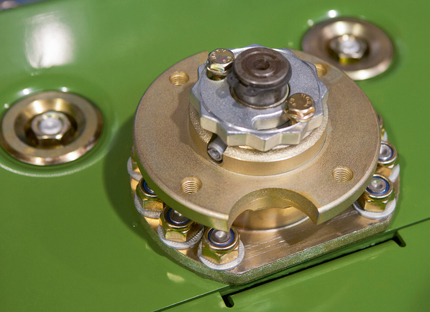

If the system is suddenly overloaded, the impact is not directed to the spur gears in the driveline, instead a roll pin in the sprocket drive shaft shears off. The pinion shaft continues spinning, jacking up the disc in question, moving it out of the risk zone and the orbit of the neighbouring discs. As a result, SafeCut prevents damage to the spur gears and the neighbouring discs. The roll pins can be replaced in just a few minutes and cost next to nothing.

Each disc on the mower has its own individual impact protection. When the blade hits an obstacle the shockload is transferred to a roll pin which breaks. As a result, the disc automatically threads 15 mm up on the drive shaft.

There is no load on the roll pins during operation. The bearing is tensioned by a nut and two clamping screws. As a result, the roll pins do not suffer from material fatigue and will break only at their inbuilt load level - even after many hours of use.

The ActiveFlow cutting discs feature double protection. The cutting discs operate in the shielded area of the cutterbar and do not protrude beyond the sliding skids. Additional protection comes from the standard SafeCut cutterbar protection system.

The pin secures cat I and II top links and is locked to stop it turning.

The oil lines are tidily stored in a holder when the machine is not in use. The hose couplers have handles for easy attachment and removal.

Drive power flows through a frictional direct drive of universal shafts and gears for maximum efficiency even in difficult conditions.

You can side-shift the machine by refitting the pins on the link arms. This way you get the full cutting width despite different wheelbases when working on slopes and in combination with a front mower.

The sturdy three-point headstock features a bracket to store the driveshaft after the machine is removed from the tractor.

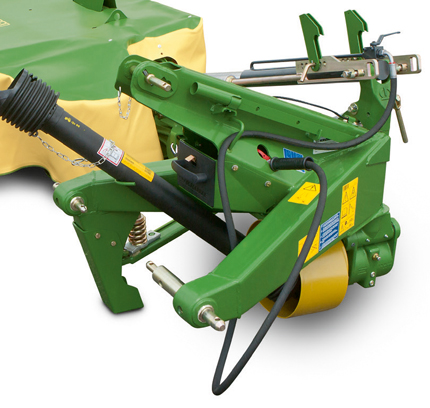

Offering a large up/down travel range, the ActiveMow disc mowers are perfect for work on slopes and in undulating and rough terrain.

The break-back system relies on an adjustable coil spring, which responds instantly and dependably and allows the mower to swing back and up when impacting a foreign object.

For convenient attachment/removal of the machine, release the spring tension simply by operating the latch on each spring. Such latches are specified on the ActiveMow R 240, R 280, R 320 and R 360 models where they eliminate the need for unhooking the coils.

The ActiveMow R 280, R 320 and R 360 models have three adjustable coil springs – one that adjusts the inboard arm and two that control the outboard arm.

The ActiveMow R 240 has two coil springs that are adjusted without tools. The inboard spring is adjusted on a spindle, the outboard spring by refitting a pin.

The low-deadweight ActiveMow R 200 has only one coil spring that provides infinitely variable adjustment.

The ground pressure of the cutterbar is controlled by adjusting the tension of the coil springs. The ActiveMow R 240, R 280, R 320 and R 360 models have pins that reset the spring tension without the use of tools. The ground pressure drops as the spring tension increases.

Unlike a mower that swings horizontally behind the tractor, ActiveMow swings up, thereby taking less load off the front axle and increasing stability during fast road travel and work in rough fields.

It takes as little as one single-acting coupler to move the ActiveMow into work or transport position. The tap that controls the parking position is in easy reach right next to the hydraulic cylinder.

To get ready for transport, ActiveMow folds into a 100° angle position behind the tractor. Taking weight off the right wheel, it increases the road stability of the combination. The operator enjoys an unobstructed rear view in the mirror.

Stands are available as an option to store the machine either in work or transport position and save space in the machine shed during winter storage. The side guard folds automatically when ActiveMow moves into transport or park position, thereby reducing the machine’s height.

On the headland, the mower is raised hydraulically to enable convenient turns and avoid running on cut material. The link arms are not raised. A stop limits the lift range.

The right model for every field of use

| ActiveMow R 200 | ActiveMow R 240 | ActiveMow R 280 | ActiveMow R 320 | ActiveMow R 360 | ||

|---|---|---|---|---|---|---|

| Work width (m) | 2.05 | 2.44 | 2.83 | 3.22 | 3.61 |

configure

|

| No. of discs | 3 | 4 | 5 | 6 | 7 |

configure

|

| No. of top hats | 2 | 2 | 2 | 2 | 2 |

configure

|

| Power requirement kW/hp | 27 / 37 | 30 / 41 | 40 / 55 | 50 / 68 | 55 / 75 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)

![[Translate to EN:]](/fileadmin/_processed_/6/9/csm__V9H1473_100520_fa14b6ad05.jpg)

![[Translate to EN:]](/fileadmin/_processed_/e/9/csm__V9H9780_101442_dc7407e687.jpg)

![[Translate to EN:]](/fileadmin/_processed_/2/9/csm__V9H9804_101491_58d36497a3.jpg)