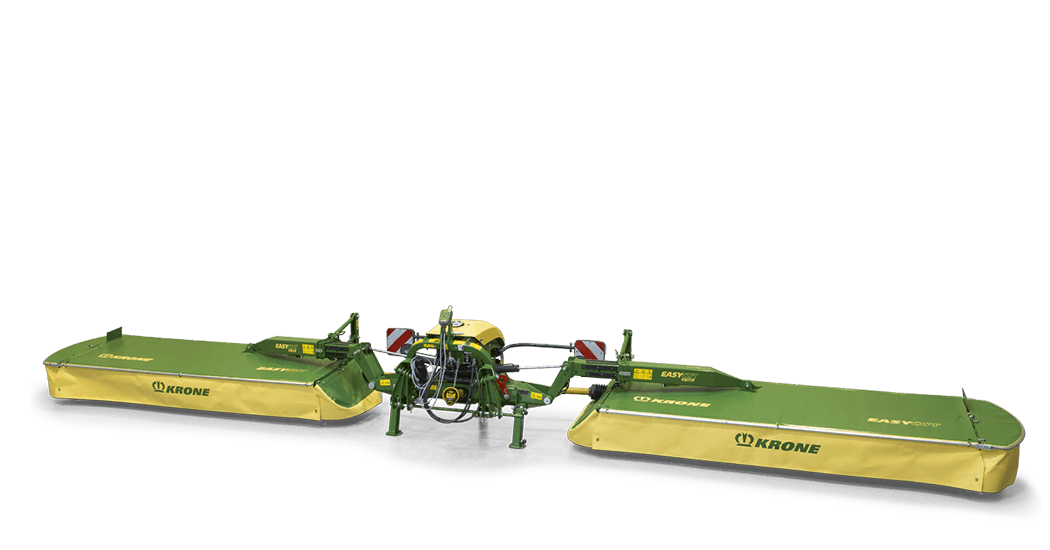

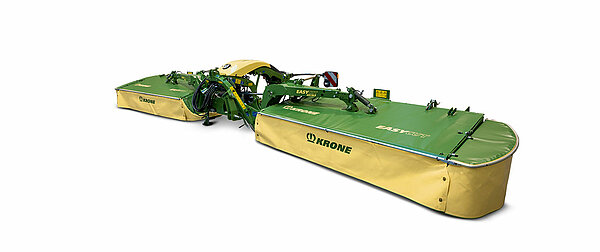

With innovative technology and excellent performance, the EasyCut B mowers set new standards in terms of efficiency. Whether dense grass, high field forage or difficult meadows – the EasyCut B models are up to every challenge. They perfectly adapt to the ground conditions and reliable follow the contour. The result: Even cuts without any compromise.

- KRONE SmartCut – Stripe-free cutting

- KRONE quick-change blades

- KRONE SafeCut – Individually protected cutting discs

- EasyCut B 1000 without conditioner

- EasyCut B 950 Collect without conditioner, with auger conveyors

- EasyCut B 1250 Fold 12.5m working width with folding cutterbar

- EasyCut B 1050 CV with BiG Swath System

- EasyCut B 880 CV / CR and B 1050 CVc – Mower combinations with conditioners

- EasyCut B 1050 CV BSS | EasyCut B 880 CV BSS – Mower combinations with CV conditioner and auger conveyors

NEW: EasyCut B 1250 Fold

Agritechnica 2025

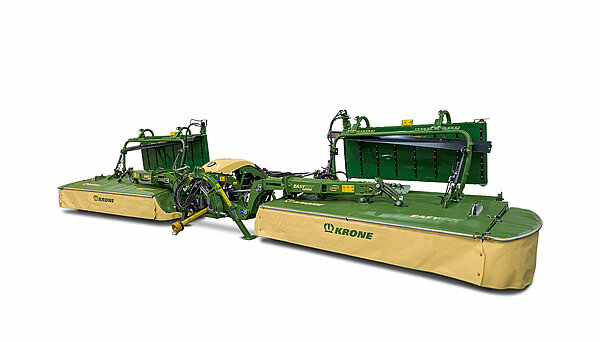

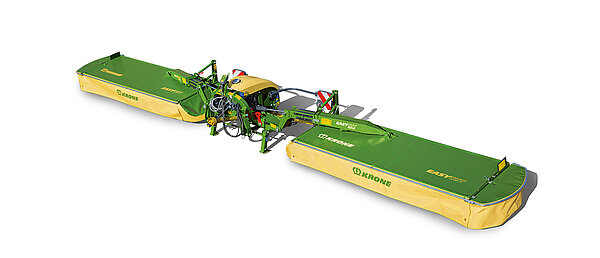

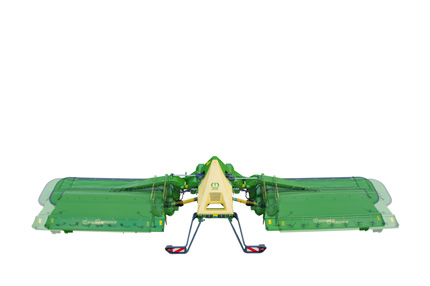

KRONE has once again delivered a major success with its latest development EasyCut B 1250 Fold. This butterfly combination works highly efficiently with a maximum working width of up to 12.50 metres and is thus optimally adapted to the sward-protecting CTF (Controlled Traffic Farming) concept via precise track guidance. Thanks to its technically-impressive design, the mower combination can be easily transported on roads: The unique and patented folding mechanism allows mower units to be folded up very compactly.

Read the news

KRONE – EasyCut B 1250 Fold

Product video

KRONE has once again delivered a major success with its latest development EasyCut B 1250 Fold. This butterfly combination works highly efficiently with a maximum working width of up to 12.50 metres and is thus optimally adapted to the sward-protecting CTF (Controlled Traffic Farming) concept via precise track guidance. Thanks to its technically-impressive design, the mower combination can be easily transported on roads: The unique and patented folding mechanism allows mower units to be folded up very compactly.

Product video

EasyCut B – KRONE mower combinations

Introducing the new EasyCut B 870 and EasyCut B 1000, KRONE adds two models to its range of butterfly combinations. Compared with the previous butterfly mowers without conditioners, the new models stand out for a modern design and curved styling, taut curtains and an optimised weight thanks to a new headstock.

KRONE – EasyCut B 880 CV BSS

With the KRONE EasyCut B 1050 CV BSS and B 880 CV BSS, swath merging can optionally also be effected by means of auger conveyors – an option unparalleled in other Butterfly combinations. Large-dimensioned augers behind the CV conditioner ensure gentle crop flow without losses. Depending on the hood position, the crops are spread centrally or deposited in partial-with swaths or individual swaths. This technology, which has been tried and tested thousands of times on the BiG M self-propelled machines, is now also being used on the Butterfly combinations.

Product features

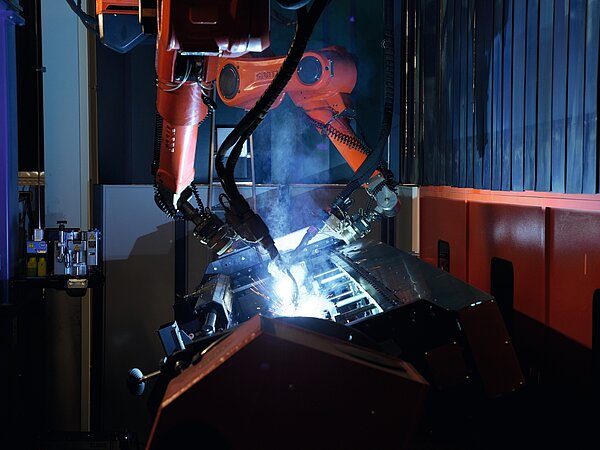

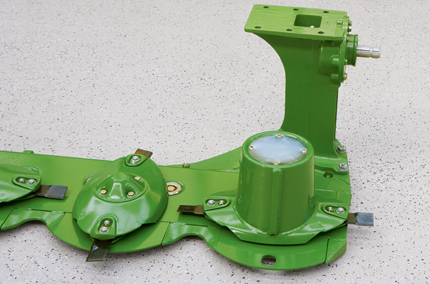

The all-round welded, enclosed cutterbar is maintenance-free and remains reliably sealed and dimensionally stable even after many years of use. Special cleaning processes during production enable lubrication for life and make the usual oil change superfluous.

As the central element of every disc mower, the cutterbar is a particular focus at KRONE: Welded all round and lubricated for life, it is manufactured using the latest welding robot and CNC technology – for maximum precision, maximum durability and the highest quality standards.

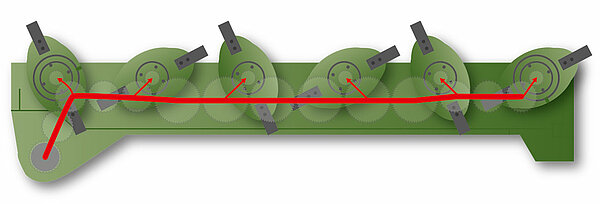

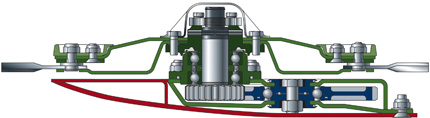

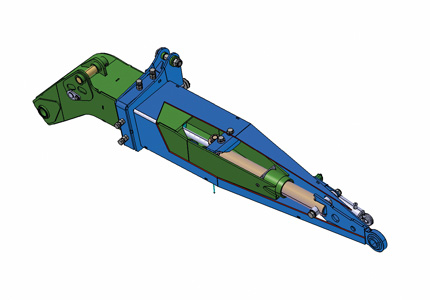

The satellite drive in the cutterbar – developed by KRONE and successfully used worldwide for decades: Large spur wheels with up to 59 teeth transmit the main drive forces to the end of the cutterbar. The large-diameter gears rotate at reduced speeds, with a higher number of teeth meshing with the neighbouring spur wheels. This design stands out for quiet running, maximum power transmission and a long service life. Each disc is driven by its individual auxiliary gear which minimises the load on the disc.

The cutterbar is driven by the angular gearbox directly behind the inner mower drum. This guarantees blockage-free operation on the headland and in awkwardly shaped fields.

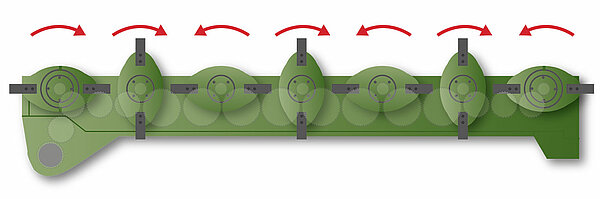

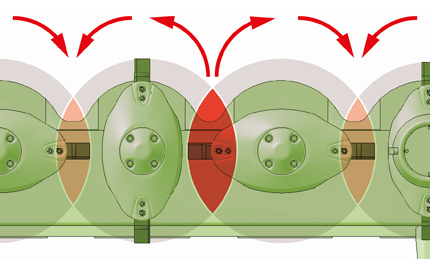

With discs spinning in the B direction of rotation, EasyCut spreads the crops across the full width. All discs turn in pairs in alternating directions, spreading the material across the working width for faster and more uniform wilting.

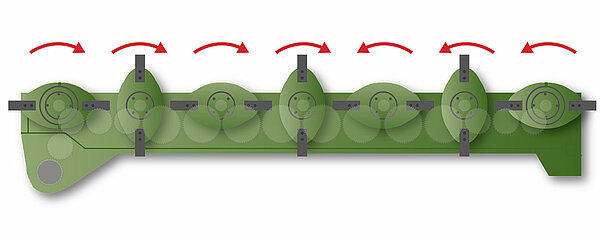

To prevent the mown forage from being run over by the tractor wheels, the bearing housings are positioned so that the discs rotate towards the centre.

The spur gears are arranged in a forward position and eccentrically inside the bearing housing right under the discs. The small auxiliary spur gears are removed from above, the massive main gears gearbox from the side.

With some cutting discs turning alternatingly in pairs towards each other and others turning away from each other, it was necessary to redesign the degree of blade overlap to ensure cleanest cuts. The blade overlaps between the discs turning outwards is thus larger (SmartCut). This is perfect for achieving stripe-free swaths of young crops on slight inclines. In addition, the blades turning to the rear are set further apart to encourage a smooth flow of large volumes of crop.

The wedge-shaped cutterbar offers many height setting options. The spur gears run in massive double bearings, allowing the cutterbar to handle extremely high loads.

Worn blade fixing pins and wear parts are not an issue for KRONE EasyCut, because the modular design of the discs allows you to replace them individually. If you like, you can opt for bolts instead of pins.

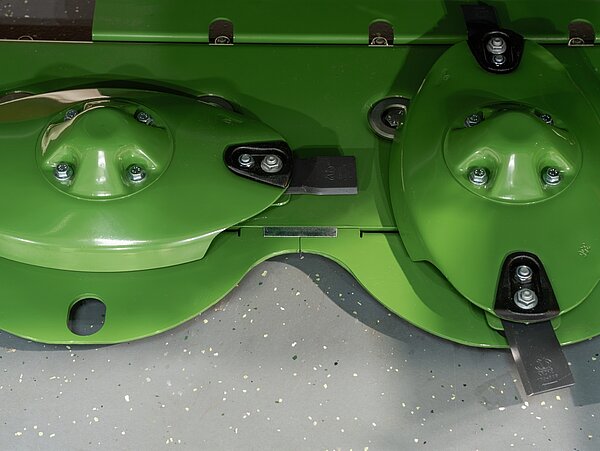

Blades of 112 mm length orbit with a generous overlap, producing the typically clean cuts and feeding the material to the rear in a consistent flow.

The blades are free to spin 360-deg. on their blade fixing pins. They are hard-wearing and self-cleaning, well protected and will not foul with the blades on the neighbouring discs.

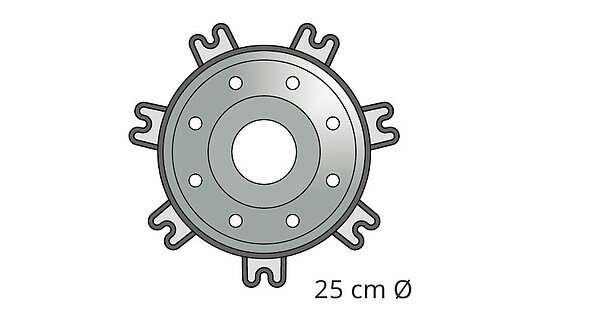

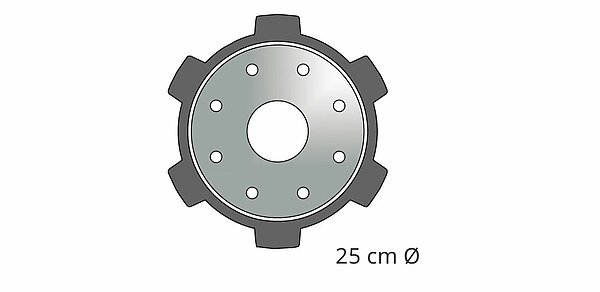

The new optimised cutting discs of the EasyCut B and F models impress with innovative details: A reinforced contour ensures even more stability and resilience. Thanks to the new laser head seam and edge coating, the cutting discs are optimally protected against wear, significantly increasing their service life.

The new sliding skid with full supporting surface improves sward protection and reduces wear. The result: Improved contour guidance, longer service life with a precise cutting pattern – even under the most demanding conditions.

Quick-change blades are a must for many farmers and contractors, These blades are quick and easy to reverse or replace in situ.

If the system is suddenly overloaded, the impact is not directed to the spur wheels in the driveline, instead a roll pin in the sprocket drive shaft shears off. The pinion shaft continues spinning, jacking up the cutting disc in question, moving it out of the danger zone and the orbit of the neighbouring discs. As a result, SafeCut prevents damage to the spur gears and neighbouring discs. Replacing the roll pin takes a few minutes and is not very costly.

Each disc on the mower has its own individual impact protection. When the blade hits an obstacle the shockload is transferred to a roll pin which breaks. As a result, the disc automatically threads 15 mm up on the drive shaft.

There is no load on the roll pins during operation. The bearing is tensioned by a nut and two clamping screws. As a result, the roll pins do not suffer from material fatigue and even after many hours of operation they will break only at their inbuilt load level.

Orbiting within the sphere of the mower bed and never protruding beyond the skids, the EasyCut discs benefit from two-fold protection. Additional protection is provided by the standard SafeCut cutterbar protection system.

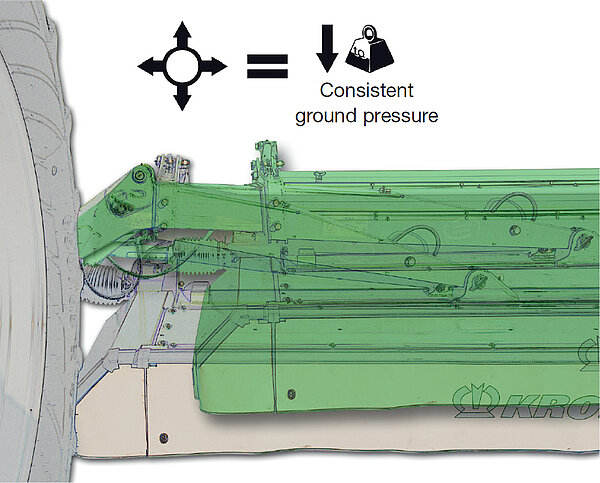

Maintaining a uniform bearing pressure across the entire working width is a requirement that is thoroughly met by KRONE disc mowers. As the cutterbar is heavier on the inside because of the drive, KRONE positions the cutterbar in the centre of gravity and not in the centre. In conjunction with the short outrigger arm and guidance via additional suspension arms, this ensures maximum stability with low weight – ideal for tough, practical use.

For optimum mower control, position the tractor’s lower links in such a way that the two control arms on the mowers are level. The red arrow indicates the correct height of the lower links.

The mower is mounted on a bolt which pivots in a ball joint eye at the end of the outrigger arm. This design provides plenty of movement and exemplary contouring. In addition, an impact damage protection system is integrated in the headstock as standard.

The parallelogram arm suspension absorbs lateral forces and guides the unit in direction of travel. At the same time, it helps reduce the load on the outrigger arm and the suspension system in the machine’s centre of gravity.

The standard deflector sheets for wide spreading can be adjusted. You either form the material into narrow swaths on wet and boggy terrain or spread it across the work width for faster wilting. Smart Connect Solar is another option that can be used to localise the machine.

Select 900 rpm for intensive treatment and 600 rpm for less intensive conditioning. Setting the required conditioner speed is easy on the manual gearbox.

The tine-to-counter sheet clearance is adjusted by a continuous notch system and presents another option to alter the degree of treatment. As you reduce the gap you increase the intensity of conditioning.

The V-shaped steel tines on each mower span across the entire work width and from the left to the right drum, providing a uniform crop flow across the full working width and optimum forage conditioning. Deflector sheets are available for wide spreading and even faster conditioning.

The V-tines of the EasyCut mower are made from hardened steel and mount at a steep angle, treating the forage intensively and powerfully. The tines pivot to the rear when hitting a foreign object. As a standard, the tine conditioners of the EasyCut B mower combinations are equipped with adjustable conditioning sheets that support the tines and ensure intensive conditioning.

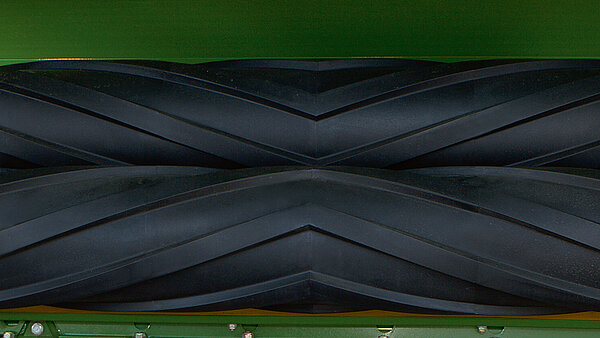

The counter-rotating M-Rolls mesh to crush the crops and yet leave a sufficiently wide gap for the material to pass through. The result is a uniform conditioning quality for uniform wilting and no fragmentation – the perfect system for lucerne, for example.

The top roller of the M-Rolls is driven synchronously by a gearbox on the outer side of the cutterbar of the bottom roller. bracing you for wet and heavy crops.

The large-diameter CR conditioner rollers deliver a smooth and consistent flow of crop and have a low power input.

The full-width CR rollers ensure a uniform conditioning effect across the entire work width The rubber coating ensures a long lifetime. The interlocking surfaces of the squeeze rollers give intensive but gentle conditioning whilst avoiding losses.

The top roller suspends from a spring which ensures a continuous flow in inconsistent growth and allows foreign objects to pass the system trouble-free. Thanks to a stepless adjustment system, the operator adapts the roller distance and contact pressure steplessly to current yields. The conditioning rollers are driven by gearboxes. The box that drives the bottom squeeze roller is integrated in the gearbox that powers the cutterbar.

The swath width of the EasyCut B CV and CR Collect can be preset by means of a hole pattern. The fine adjustment in keeping with the harvesting conditions is made via the belt speed and the optional accelerator rollers.

Powerful hydraulic cylinders ensure safe lowering and lifting-out of the cross conveyor belts during ongoing operation. The drive is switched on and off fully automated. For maximum flexibility, choose between partial width swathing (top), central spreading (centre) or swathing (bottom).

Adjustable swath flaps optimise the crop flow and flow to the cross conveyor belts.

The cross conveyor belts are driven by an on-board hydraulic system which is cooled by a separate oil cooler.

Operators of ISOBUS-compatible EasyCut B CV and CR Collect models adjust the swath width electrically by altering the belt speed and the height of the optional accelerator rollers. Maximum operator comfort is achieved with the electric height adjustment.

For loss-free crop transfer to the cross conveyor belt, the EasyCut B CV and CR Collect models are equipped with a divided conditioner tray.

Die EasyCut B Modelle können im Anbaubock in zwei Positionen befestigt werden. Je nach Traktor kann entweder der Schwerpunkt näher an die Hinterachse gebracht oder alternativ mehr Raum beim Anbau der Maschine geschaffen werden.

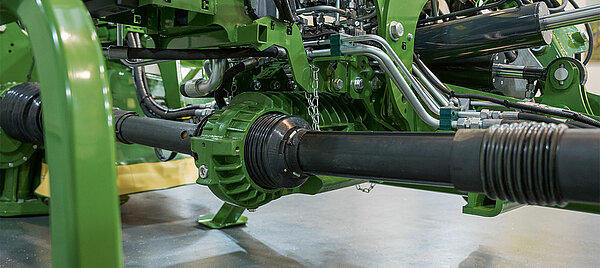

The mower combination is powered by a 1,000 rpm PTO speed. The main gearbox in the middle splits the powerflow and sends it to the downstream universal shafts. The drive train is protected by break-back systems and overrunning clutches.

The mower combinations have a standard non-stop impact damage protection system that offers an infinitely variable trip force set on a spiral spring. When the machine hits an obstacle the impact damage protection system trips immediately and the mower swings up to 1.60 m rear and upwards. Once the obstacle has been passed the cutterbar moves automatically back into work position.

The headstock is protected by a newly designed hood. The befitting guards on the mower decks are thin and taut, reducing the build-up of material and protecting the cutterbar from damage by stones.

The weight-optimised headstock is coupled in the three-point linkage with three-fold buttressed pins, a design that moves the centre of gravity closer to the tractor, enabling the use of smaller tractors.

The DuoGrip centre of gravity mounting allows all mowers in the combination to maintain a consistent bearing pressure across the entire working width. You simply set the pressure hydraulically from the cabin. It is then indicated on the pressure gauge. The system delivers optimum contouring and perfect cuts.

The independent machine lift-out feature, a standard specification, makes it easy to cut awkward corners. Simply select the specific mower on the operation box and then raise it hydraulically.

EasyCut B 1000 operators set front-rear overlaps on the move and infinitely variably on the cab-based terminal. At the same time, they can vary the distance between the other rear mowers between 2.08 m and 2.80 m. When combining this model with a 3.16 m front mower, the overlap on both sides ranges from 18 cm to 59 cm. This allows operators to adapt the combination flexibly to current conditions and maintain high acreage outputs and a clean cut.

In the EasyCut B 870, the outrigger arms of the mower units can be mounted in two positions. For slopes or heavily contoured fields, the distance between the mower units can be set to 1.99 m. Using a front mounted mower with 3.16 m working width, this yields an overlap of 59 cm on each side with a total working width of 8.31 m. For level ground, the distance can be set to 2.30 m, resulting in an overlap of 43 cm on each side and a total width of 8.62 m, and thus a higher acreage output.

You can select various machine functions from the control box. These are then executed by the tractor’s hydraulic system. This technology requires only a single-acting and a double-acting spool.

LED lights at the rear and a brake light with an integral red-white reflector panel provide adequate road safety.

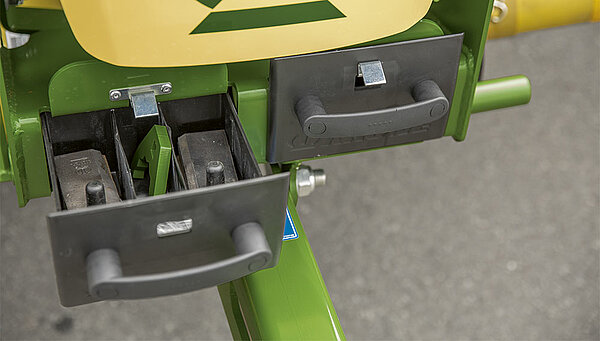

Two removable spare blade drawers are standard equipment on the mower combination. Here you store your spare blades to have them readily at hand. The blades are quick-change as standard.

The mowers fold into a 95° transport position, slightly leaning to the middle. The side guards drop automatically into transport position as the units fold into the vertical. By means of a hole pattern, the headstock can be mounted in two positions so that the machine is mounted as close as possible to the tractor. With all tractor types, there is sufficient room for safe hitching.

Hydraulic check valves lock and release the mowers automatically when these are moved into work or transport position.

Measuring only less than 4m high and less than 3m wide, these mower combinations absorb very little storage space. They are parked on sturdy support jacks. Extra stability on the EasyCut B 1000 comes from the external support on the cutterbar and protective frame (optional on EasyCut B 870).

With a total weight of just 3,850 kg, the EasyCut B 1250 Fold protects the soil and sward in the long term and effectively reduces soil compaction. The low weight also results in noticeably lower diesel consumption and significantly reduces wear on the tractor. The larger working width also increases efficiency, thereby reducing operating costs in the long term.

With a transport width of less than 3 m, the EasyCut B 1250 Fold guarantees maximum safety on the road. With a transport height of less than 4 m, it also remains compact and easy to transport.

The EasyCut B 1250 Fold can be ideally combined with the EC F 320, 360 and 400 front mounted mowers. This selection enables optimum adaptation to different requirements and ensures maximum efficiency for every application.

The EasyCut B 1250 Fold has a hydraulic side shift which enables a variable working width from 11.30 to 12.50 metres. Both outriggers can be telescoped outwards by 60 cm – conveniently and precisely from the cabin. This allows the mower to be optimally adapted to different operating conditions and therefore impresses with its high flexibility, efficiency and ease of use.

The EasyCut B 1250 Fold is ideal for use in Controlled Traffic Farming (CTF) systems. With an impressive working width of over 12 metres, it enables precise track guidance, sufficient overlap and sustainably reduces soil compaction. Thanks to the perfect integration into CTF concepts, users benefit from more efficient work processes and greater land conservation – a further contribution from KRONE to future-orientated agriculture.

The patented folding mechanism of the EasyCut B 1250 Fold from KRONE sets new standards in terms of ease of use and transportability. The automatic sequence-controlled slewing gear swivels two cutting discs per side hydraulically behind the cutterbars – simply by pressing a button directly from the cabin. This allows the mower to switch from transport to working mode in next to no time. The transport height remains under four metres and the transport width under three metres. Compact on the road, powerful in the field – for maximum efficiency during practical use.

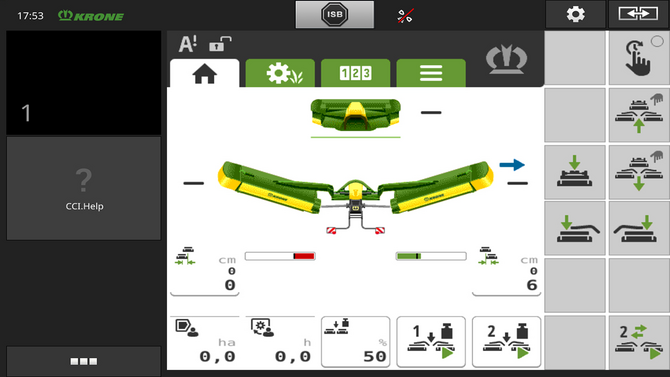

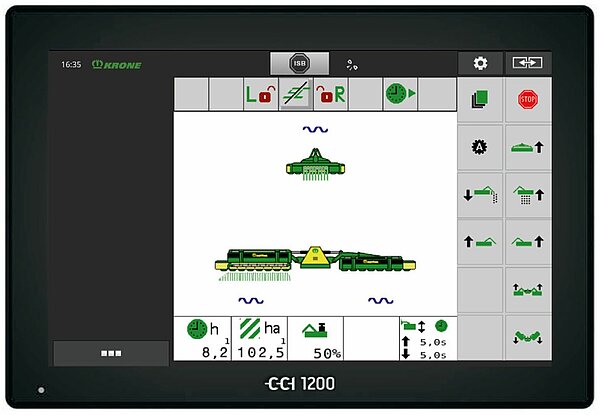

As an option, use the ISOBUS-capable Comfort control unit to operate the mower unit function via the tractor's terminals. The DS 500, CCI 800 or CCI 1200 with touch screen allow intuitive and covenient operation via Load Sensing.

In the EasyCut B 950 Collect, preselect the hydraulic functions via the PreSelect DS 50 or alternatively via the terminal using the PreSelect Digital. They will then be carried out by the tractor's control units.

For safe road transport, the curtains on the sides fold up automatically. The transport height is less than 4 m.

To minimize losses when working along field borders, operators can hydraulically switch between spreading and swathing – separately by mower, on the move and from the convenience of the cabin. This will not change the mowers’ working position. Having one mower swath the crop is useful when opening a field and when cutting around obstacles. This option is also very useful later during the harvest when combined with a KRONE four-rotor rake.

A hydraulic swath cloth is available for those who seek even more uniform swaths. When the B 950 Collect moves from the road to the headland position the swath cloth is sequence controlled into its horizontal working position. This option is particularly useful in wedge-shaped plots or when wide spreading on one side.

The EasyCut B 950 Collect mower features hydraulic suspension of the mower units, which allows operators to adjust the bearing pressure steplessly using the electric operation box and pressure gauge, that is easy to read, in the cab – for best contouring even in very difficult conditions.

The optional combi skids increase the cutting height from 50 mm to 120 mm and allow operators to cut different crops like grass and green rye at different heights.

Operators can raise one mower when cutting wedges. Simply select the mower that is not in work on the electric operation box and raise it.

The DuoGrip system suspends each unit in its centre of gravity and provides extra guidance by lateral arms for superior ground contour hugging. The rear lights can be raised hydraulically as an option to clear the way for more material to pass through this area. Lowered into transport position, they increase road safety.

The sturdy 45 cm diameter cross augers are powered by an angular gearbox and revolve at a consistent speed of 750 rpm, giving maximum efficiency and productivity. Arranged closely behind the cutterbars, these auger conveyors feed large volumes of crop in a consistent flow from the mowers to the middle of the combination, forming a tidy and uniform swath that is cleanly gathered by the following harvesters.

The cover hoods behind the auger conveyors open and close hydraulically for convenient selection of one of the three swathing modes from the cab: swathing, independent swathing or wide spreading on one side.

The speciality of this feature is the fact that it maintains the pressure inside the compensation tanks of the hydro-pneumatic system – courtesy of extra spools and the circuit of the single-acting hydraulic connection with free return line. The advantage of this system is that it maintains a uniform mower relief in undulating terrain and when working with different working widths.

The compact three-point hitch integrates the lifting cylinders, control block and accumulators to reduce the weight and load on the tractor hydraulics. The easy-to-open hood also offers effective protection.

The responsive impact damage protection system moves the machine reliably up and to the rear. The system tripping force is set steplessly on the spiral springs.

The standard impact damage protection system on EasyCut B 1000 CV and B 1000 CR offers you peace of mind as you cut along borders, fences and obstacles that may suddenly appear. When one of the side mowers hits an obstacle it swings approx. 1.50 m to the rear and returns automatically into its initial position once the obstacle is passed.

The ISOBUS terminal allows operators to extend/retract the rear mounted mowers hydraulically, either individually or symmetrically by up to 40 cm. In addition, the standard-fit operation device adjusts the working width simultaneously on both sides.

The outrigger arms on the EasyCut B 1000 CV and B 1000 CR side mowers extend and retract on telescoping arms. If the side mowers are moved in the opposite direction, the overlap relative to the front mower and the working width of the mower combination changes. When using an EasyCut front mower with a 3.16 m working width, you can set overlaps from 130 to 530 mm on each side. To avoid striping on slopes, the side mounted mowers can be shifted to the same side.

Double-acting hydraulic cylinders extend and retract the outrigger arms for the side mowers. on the move thereby varying the degree of overlap.

The rear mower units are raised by compact double cylinders, which simplifies operation. The single-acting cylinders lift the mowers into the headland position; the double-acting cylinders fold them into the transport position.

For a reduced transport height the side guards on the rear mowers fold up.

All three mowers lift and lower at the touch of a button when the tractor approaches the headland. You can operate the front hydraulics of the tractor from the control block on the rear mower. Cutting wedges or awkward plots is easy as you can work with one or two mowers. The machine is not running on cut material. EasyCut B 1000 CV not only delivers an exceptional performance in large fields but also in smaller plots, producing clean cuts and perfectly conditioned forage.

Store the side mowers on their sturdy support jacks in upright position and save space for more equipment in your shed.

Using only one cross conveyor belt and the subsequently reduced spreading width saves costs and time and reduces compaction if a four-rotor centre rotor rake is then used.

If the mower combination uses parallel back and forth operation with only one cross conveyor belt, the EasyCut B 1000 CV will produce four swaths with a total width of 13.00 m from a working width up to 20.20 m – perfect for the four-rotor rake from KRONE.

Operate only one cross conveyor belt to clear a pass along the border for hassle-free work for the following harvester.

Raise the cross conveyor belts and spread the material across the full width. Wide spreading of the material speeds up wilting and helps achieve target dry mass rates faster.

The Collect System groups three passes into one – cutting, conditioning and swathing, thereby reducing the number of passes and the risk of compaction and damage to the turf and of course crop contamination.

Cutting whole crop silage requires powerful machines with plenty of clearance. KRONE uses extra wide cross conveyor belts for mower combinations with the Collect System. With a belt width of nearly one meter, even the largest amounts of crops are safely conveyed to the centre. Depending on the crop growth and the desired shape of the swath, operators can adjust cross conveyor belt speeds hydraulically from the tractor seat.

When the mower is folded in, the side guards automatically fold in as well. With a transport height of under 4 m at approx. 25 cm ground clearance and a transport width of under 3 m, safe road travel is guaranteed.

With the mower units folded in, the machine can be parked conveniently and safely on the optional telescopic support jacks – a very convenient and space-saving solution.

The revised hood on the headstock and the cloths mounted on the protective frames of the mower units reduce potential deposition and provide stone-chipping protection. They are easy to replace when necessary.

For safety on the road, the LED lighting is combined with a red-and-white reflecting warning panel in the rear. In the field, it can optionally be lifted hydraulically so that it will not interfere with the crops.

The mower combinations have a standard NonStop impact damage protection system that offers an infinitely variable trip force set on a spiral spring. When the machine hits an obstacle the mower unit quickly wings to the rear and downwards. Afterwards, it automatically returns to its initial position.

The mowers are attached by means of a compact, weight-optimised three-point hitch category 2 or 3. The centre of gravity of the machine is close to the tractor. The new hood protects the actively regulating hydraulic relief system.

The depositing plate and thus the angle in which the crops leave the machine can easily be adjusted via crank handle. Specifically the Collect models offer perfect adjustment of th crop flow of the machine.

The roller conditioner in the EasyCut B 880 R provides intensive yet gentle conditioning, required for example for clover and lucerne. The crops are crushed by two counter-rotating intermeshing rollers without any rolling losses. Choose between polyurethane and steel rollers, so-called M-Rolls.

By means of the adjustable deflector sheets, the spreading width of the crops can be set so that no tractor wheel will run over it. In this way, you can directly influence the drying process in consideration of crop moisture and weather conditions. This setting also ensures that the following work steps are better coordinated.

Use the crank handle to change the distance between tines and baffle sheet, and thus the conditioning intensity. You can also control the intensity by setting the rotational speed of the conditioner via manual gearbox to 900 or 600 rpm.

With a total of four high-performance LED lamps – two on the outrigger arm and two on the headstock – every working area is illuminated optimally. The particularly bright light ensures a high level of productivity even when it is dark. The LED working lights are optionally available on the new butterfly combinations.

The mower combinations EasyCut B 880 CV (Collect) and B 1050 CV (Collect) are equipped with V-shaped steel tines. They intensively condition the crops over the entire machine width to accelerate the drying process. KRONE's CV tines conditioners are renowned for their longevity, robustness and efficiency. Their large diameter and standard conditioner gearbox ensure a homogenous drying process.

As an alternative to the standard sliding skids, optional combi and high-cut skids with quick-change system are available. The cutting height can thus be set between 50 mm to 120 mm so that you can also mow field grass and whole-crop silage fields at a perfect stubble height.

Mounted centrally, the main gearbox with a PTO speed of 1000 rpm sends the tractor power down the straight drivelines to the mower units at both sides. Overload clutches and freewheels protect the mower and tractor from possible damage. The triple tube universal shafts enable a maximum working width of 10.45 m on the EC B 1050 CV Collect.

The EasyCut B 880 CV and CR (Collect) can be controlled via the new preselection operation PreSelect, or – optionally available for the EasyCut B 880 CV and CR Collect – via ISOBUS for even greater convenience. The EasyCut B 1050 CV (Collect) are equipped with ISOBUS Comfort control unit as a standard.

The DuoGrip system suspends both mowing units in their centre of gravity and guides them via two arms. The bearing pressure shown on the pressure gauge can be set hydraulically from the tractor via the operation box or ISOBUS terminal. – for optimum ground adjustment and best contour following even in very difficult conditions.

The working width of the EasyCut B 1050 CV (Collect) can be hydraulically adjusted stepless from 9.30 m to 10.45 m via the telescopic outrigger arms. In conjunction with an EasyCut F 360 CV, it is thus possible to set an overlap of around 75 cm to 18 cm, depending on the properties of the field. For the EasyCut F 400 CV Fold, an overlap between 97 cm and 40 cm can be set In this way, you will always achieve extremely clean cuts with the highest possible acreage output. An EasyCut F 320 can also be combined.

In the EasyCut B 880 CV and CR (Collect), the outrigger arms of the mower units can be mechanically adjusted to a working width of 8.52 m or 8.72 m. Depending on the front mounted mower used, the overlap can be adjusted to the respective conditions. In level, relatively even fields, a higher working width yields maximum acreage output. On slopes or in heavily contoured field sections, a narrower working width brings more overlap and thus stripeless cuts.

The rear-mounted swath flap can be continuously adjusted to ensure optimum feeding of the cross conveyor belts via a perfect crop flow. The divided conditioner tray furthermore ensures loss-free transfer of the crops to the cross conveyor belt.

An oil pump connected to the main gearbox operates the supplies own on-board hydraulic system. Controlling the 910 mm wide cross conveyor belts, it relieves the tractor hydraulics.

Mowing with one cross conveyor belt only is particularly practical for working along borders, where it allows for safe working of the following machines. Furthermore, one up-and-down operation and the resulting narrower swathing width save costs and time if followed by a four-rotor centre rotor rake. Also, this procedure reduces compaction.

The mower combinations EasyCut B 880 CV/CR Collect and B 1050 CV Collect are equipped with two cross conveyor belts each which safely move the crops to the centre, even large crop volumes typically found in whole crop silage fields. The mower combinations group three passes into one – cutting, conditioning and swathing.

The drive of the auger conveyors is located at the outside of the mower units. This placement ensures a smooth and efficient crop flow so that the material can be easily conveyed into the swath without being obstructed. Arranging the drive on the outside furthermore contributes to an optimal weight distribution and stability of the EasyCut B 1050 CV Butterfly combination.

The KRONE BiG Swath system is ideal for harvesting whole crop silage. It allows for clean and complete merging of the entire forage material in one wide swath. The auger conveyor ensures gentle, loss-free transport of the crops from the conditioner to the swath – and thus premium forage quality.

The efficient merging of the crops to form one particularly wide swath optimises the reception and processing by the harvester. The result is an increase in forage harvesting productivity.

The swath hoods can be conveniently opened and closed from the cabin. At the touch of a button, the cut grass can be distributed over a wide area, deposited on one side or conveyed to the centre. Opened wide, the swath hoods present the material in a fluffy and uniform swath.

Choose the optional BiG Swath System (BSS) to equip the EasyCut B 1050 CV and B 880 CV with large 45 cm diameter auger conveyors. Thanks to the hydraulically telescopic outrigger arms, the overlap to the front mounted mower and the width of the swath can be flexibly adjusted to the prevailing conditions.

The position sensor can detect the working position (active) and transport position (inactive) by the alignment of the SmartConnect Solar. With a stored working width, the SmartConnect Solar can also be used as a hectare counter. Alternatively, it is possible to record the loads on transport vehicles by opening/closing the tailgate.

As the KRONE SmartConnect Solar has an autonomous power supply and can be mounted regardless of the manufacturer, it is ideal for use on rental machines. In this way, you always know where your rented machine is. The precisely documented working hours and acreage output enable transparent and accurate invoicing of the rental machines.

With this autonomous telemetry unit, even simple machines such as mowers, tedders, rakes and other implements without their own electronics can be integrated into a digital data management system.

The right model for every field of use

| EasyCut B 870 | EasyCut B 1000 | EasyCut B 950 Collect | EasyCut B 870 CV | EasyCut B 870 CV Collect | EasyCut B 870 CR | EasyCut B 870 CR Collect | EasyCut B 880 CV | EasyCut B 880 CV Collect | EasyCut B 880 CR | EasyCut B 880 CR Collect | EasyCut B 1000 CV | EasyCut B 1000 CV Collect | EasyCut B 1000 CR | EasyCut B 1000 CR Collect | EasyCut B 1050 CV | EasyCut B 1050 CV Collect | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Work width (m) | 8.31 / 8.62 | 9.28 / 10.10 | 9.45 | 8.70 | 8.70 | 8.70 | 8.70 | 8.52 / 8.72 | 8.52 / 8.72 | 8.52 / 8.72 | 8.52 / 8.72 | 9.30 / 10.10 | 9.30 / 10.10 | 9.30 / 10.10 | 9.30 / 10.10 | 9.30 / 10.45 | 9.30 / 10.45 |

configure

|

| Transport height at 250/200 mm ground clearance (m). Transport height at 250/200 mm ground clearance (m) | 3.60 | 4.00 | 4.00 | 3.80 | 3.80 | 3.80 | 3.80 | 3.80 | 3.70 | 3.70 | 3.70 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 |

configure

|

| No. of discs | 10 | 12 | 12 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 12 | 12 |

configure

|

| No. of top hats | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 2 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

configure

|

| Power requirement kW/hp | 88 / 120 | 100 / 140 | 145 / 200 | 110 / 150 | 125 / 170 | 110 / 150 | 125 / 170 | 110 / 150 | 125 / 170 | 110 / 150 | 125 / 170 | 130 / 180 | 145 / 200 | 130 / 180 | 145 / 200 | 150 / 200 | 150 / 200 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)