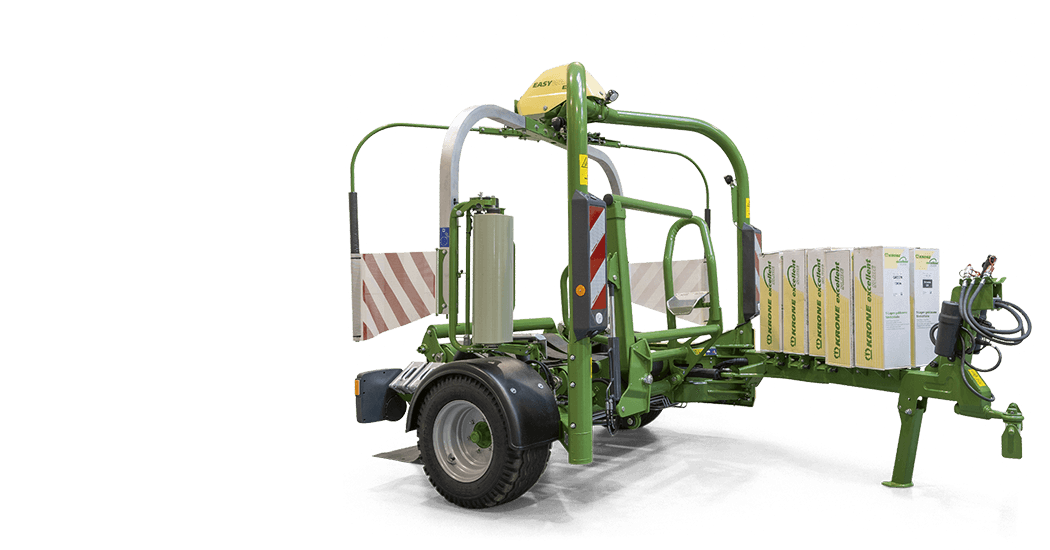

The KRONE EasyWrap 165 T offers convenient attachment to any tractor. Thanks to its trailed design, it handles the heaviest bales also when hitched to a tractor with lower lifting powers. Coupling the machine to the tractor’s lower links is fast and easy. Equally convenient is the drawbar which pivots hydraulically from transport into work position – conveniently triggered with a touch of a button from the cab.

Product video

KRONE EasyWrap – trailed bale wrapper for professionals

KRONE adds a new machine to its round bale wrapper programme: the new double-arm EasyWrap 165 T which follows the EasyWrap 150 launched in summer 2020. Wrapping 1.00-1.65m diameter bales, the 165 T is a truly high-capacity machine where a double arm orbits around the bale for wrapping. The machine lifts up to 1,650kg bales and wraps them at speeds of up to 40rpm achieving maximum efficiency and daily productivity.

Product features

Eight film holders can be ordered as an option. Mounted at a low height, the holders make for convenient handling of the film rolls.

The EasyWrap 165 T is coupled to the tractor’s lower link arms. This easy and convenient type of attachment is a standard feature which is particularly useful if the machine is used behind various tractors.

Operators can execute all machine functions from this external control panel on the frame, which is a great help when changing film rolls.

At the end of the wrapping job the wrapper turns into a bale collector by carrying a second bale on the loading arm. After the tractor arrives at the collecting point, the finished bale is lowered to the ground and the second bale is wrapped.

The bale turner is available as an option. It turns the bale on its face so it cannot roll downhill. For road transport, it folds up easily and fast operated from the cab.

The EasyWrap 165 T is able to unload the finished bale on the move for maximum productivity without stops. To do this, it tips the table far to the rear. An optional mat helps avoid the film is poked by the stubble.

A sturdy loading arm picks up the bale gently and places it equally gently onto the wrapping table. As the bale is grabbed at ground level it is neither squeezed nor damaged. The arm adjusts easily without tools to various bale sizes. All you need to do is refit a pin.

The entire wrapping cycle from picking up the bale to lowering it to the ground can be automated and executed without any interference by the operator. The cycle is triggered when the bale contacts the sensor plate on the loading unit.

At the end of the wrapping cycle, the cut-and-tie unit makes cuts the film very close to the bale cut eliminating loose film ends. A spring-loaded clamp traps the film end so it is ready for the next cycle.

The wrapping table is formed by four extremely durable textile belts that roll the bale effectively. A special coat on the rollers ensures the belts will not slip. The belts form a deep cradle that holds the bale firmly in place and where it is held in check by four bobbins or six as an option for ideal overlaps.

Depending on the gear ratio, the dispenser stretches the film to 55% to 70% ensuring efficient film use. The unit has an integrated sensor that detects a broken film. At film break, you either stop work and refit the film or you continue wrapping with one arm after halving the orbiting speed.

The quick-change system makes swapping film rolls a doddle. Swing out the film dispenser assembly, fit the new roll and thread the film into the stretcher. For added convenience, you can move the wrapping arm into the preferred position by pressing the external control.

The two wrapping arms on the EasyWrap 165 T orbit at up to 40 rpm for shortest wrapping cycles and an outstanding performance. The arm is position controlled by an angle sensor. Also, a brake fixes it in position so it always starts out from the same position – a detail that is particularly important in sloping fields. The technology ensures perfect wraps and consistent overlaps even on different tractors and different hydraulic systems.

The standard-fit 10.0/75-15.3 10 PR TL tyres (15.0/55-17 10 PR TL option) ensure ground-friendly and light-pulling performance in difficult soil conditions.

The wrapper features standard lights for safe travel on public roads. In addition to that, LED working lights can be ordered as an option for perfect visibility in poor light conditions.

The low-slung chassis brings the centre of gravity close to the ground for perfect stability in sloping fields – an important detail for loading and unloading the bale but also during wrapping.

These two ISOBUS terminals – the 8-inch CCI 800 and the 12-inch CCI 1200 – offer premium operator comfort from a touchscreen terminal with a clear menu navigation.

The DS 500 terminal with 5.7-inch touchscreen has twelve function keys for easy and convenient use.

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)

![[Translate to EN:]](/fileadmin/_processed_/8/2/csm_P1180107_178680_824dbac08e.jpg)

![[Translate to EN:]](/fileadmin/_processed_/9/e/csm_P1000180_177645_0aaa8e0573.jpg)

![[Translate to EN:]](/fileadmin/_processed_/6/c/csm_P1180074_178626_15337117d7.jpg)