KRONE Swadro - a machine you can depend on

KRONE centre delivery rotary rakes: The most comprehensive offer on the market

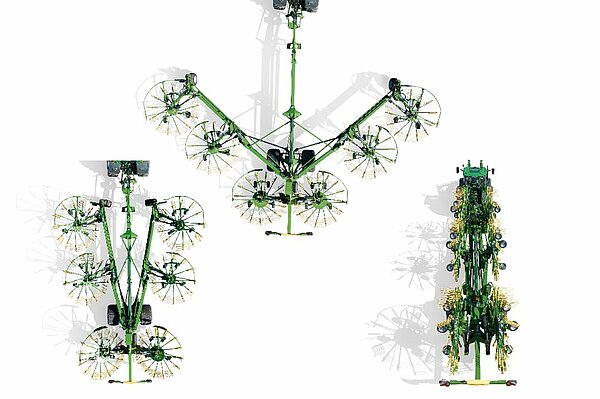

The KRONE Swadro TC line-up of rotary rakes offers the largest choice of centre delivery rakes in the market. Choose from an enormous variety of models and options – from the entry model, the Swadro TC 640 twin rotor rake as the best option for small and hilly fields, to the unique six-rotor unit, the Swadro 2000 that offers maximum efficiency and capacity.

- The pull-type cardanic suspension – Optimum contouring and cleanest rakes

- KRONE Jet Effect – Protects the sward and produces clean forage without poking into the ground

- KRONE DuraMax cam track – Perfect swath presentation and boosted harvest chain efficiency

- KRONE Lift Tines – Lifting instead of conveying for maximum raking performance and less raw ash in the forage

- KRONE Easy-Line drive concept – Mechanical drives all-round for fast changeovers and high area outputs

NEW: KRONE Swadro BaleTrain TC 880 Pro

Agritechnica 2025

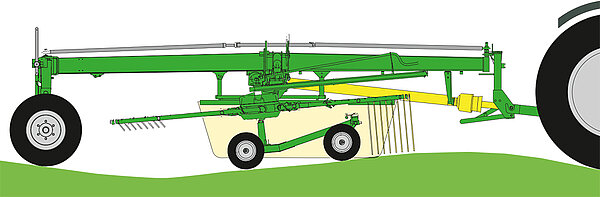

For the first time, a manufacturer is combining a rake and round baler for single person operation with maximum automation and efficiency. This combination is based on the modified Swadro TC 880 twin-rotor rake from KRONE, which merges with a KRONE round baler to form a highly efficient unit. The sole requirement placed on the baler is the ability for bottom hitching using a K 80 ball-head hitch and a PTO drive operating at 540 rpm.

Read the news

Product video

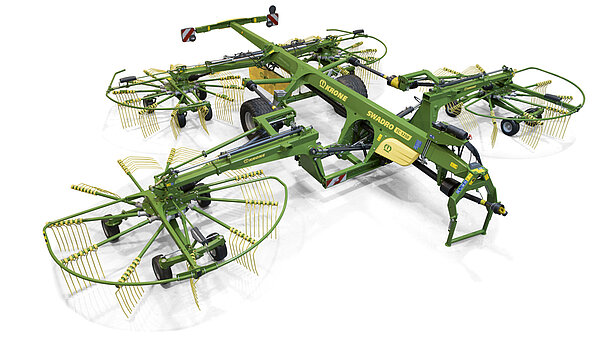

SwadroTC 1250 and TC 1370 – KRONE Four-Rotor Rakes

The new Swadro TC 1250 marks KRONE’s entrance to the high-capacity rake sector. The machine combines heavy-duty components from professional machines with the simplicity of twin rotor rakes, making the TC 1250 the ideal all-rounder for large farming operations, machinery rings and contractors. The Swadro TC 1370 four-rotor centre delivery rake makes its appearance in a modern styling and with plenty of landmark features including convenient setting options that make the job a lot easier for operators and produce optimum swaths at high outputs.

Product features

KRONE centre delivery rotary rakes – The most comprehensive offer on the market. With the KRONE Swadro TC rotary rakes, KRONE offers the largest product range in the centre rotor rake segment. Starting with the twin-rotor rake Swadro TC 640 for small areas and mountainous regions, through to the world's only six-rotor rake Swadro TC 2000 for maximum efficiency and recovery performance, a wide range of model variants and equipment options are available.

With the Swadro TC rotary rakes with centre delivery, KRONE offers the widest product portfolio on the market. Starting with the twin rotor rake Swadro TC 640 , through the entry-level model into the world of large-area rakes, the Swadro TC 1250, to the world's largest centre rotor rake, the Swadro TC 2000, KRONE offers working widths between 5.70 m and 19.00 m in this segment. In addition, you can choose from a wide range of optional equipment and operator comfort.

Two-rotor centre rotor rake combined with a round baler – for efficient swathing and baling in one operation

Six-rotor rake centre delivery: Variable working widths from 10.00 m to 19.00 m

Twin-rotor rake centre delivery: Variable working widths from 5.70 m to 6.40 m

Twin-rotor rake centre delivery: Working width 6.80 m

Twin-rotor rake centre delivery: Variable, 6.80 m to 7.60 m work widths

Twin-rotor rake centre delivery: Variable working widths from 7.60 m to 8.80 m

Twin-rotor rake centre delivery: Variable working widths from 8.10 m to 9.30 m

Twin-rotor rake centre delivery: Variable working widths from 8.90 m to 10.00 m

Four-rotor rake centre delivery: Variable working widths from 9.80 m to 12.50 m

Four-rotor rake centre delivery: Variable working widths from 10.80 m to 13.70 m

Four-rotor rake centre delivery: Variable working widths from 11.00 m to 15.70 m

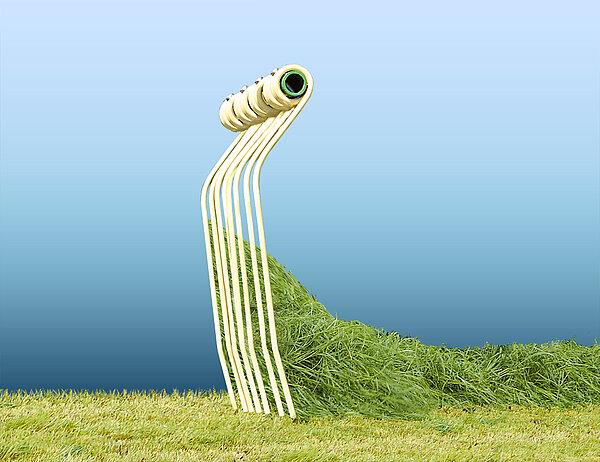

The Swadro rotor is pulled in direction of travel of the outrigger arm. In combination with the central suspension of the rotor, the rotor is always lifted out and inserted horizontally. The weight of the rotor is distributed evenly over all guide wheels during swathing and therefore adjusts optimally to the ground contours. Forage contamination and raking losses are therefore minimised.

The rotors suspend in a pull-type and cardanic configuration which provides exact guidance to the tines and optimum contouring – both in and across the direction of travel. This way the tines pick up every haulm but not a single grain of sand. Uncontaminated forage, minimum loss rates and high work rates – this is the Swadro definition of quality work.

The KRONE Jet Effect ensures the tines will not dig into the ground when the rotors lower and lift. Emulating the touch-down and take-off behaviour of an airplane, The clever design of the rotor suspension ensures there is always a maximum of clear space between the tine and the sward when the rotor lifts and lowers out and into work – an intelligent system that helps protect the sward and avoids crop contamination.

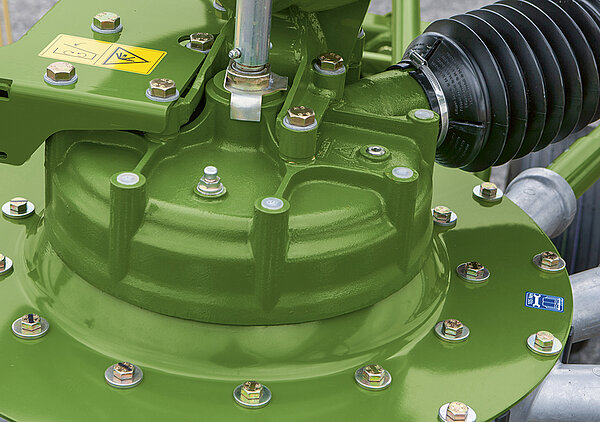

No matter how difficult the conditions, the Swadro rotor gearboxes deliver reliable performance and great stability without any servicing or maintenance. Count on these qualities.

The weather sets the pace in forage harvesting. Maintenance- free and permanently liquid greased rotor gearboxes make the KRONE Swadro a very reliable partner in your harvest campaign. Swadro is always ready to go, ensuring dependable operation in narrow harvest windows. No time is wasted on service stops. Come rain or harvester.

Stand-out features of our DuraMax cam track is the extremely small diameter and steep track design. It is this unique design and its effect that lead to the formation of optimum swaths in all conditions. The small diameter of the cam track combines with the massive size of the rollers for smooth and low-wear operation. As the tine arms follow the steep curve the tines are promptly lifted out of work, forming boxy and optimum swaths in all conditions.

The KRONE cam track features the unique Bainite structure which is obtained by a special hardening process. Accordingly, this cam track has a very durable surface and yet a flexible core, a combination that results in low wear. This type of coating also reduces rolling resistance for reduced friction, wear and power input.

Some KRONE Swadro models have foldable tine arms either as a standard feature or an option for reduced transport heights. This unique folding mechanism reduces the transport height and width in a matter of minutes without requiring the operator to remove the arms and carry them to their holder on the machine, reducing the strain on the operator and saving time and money when changing fields. Belleville springs inside the arms connect the two parts reliably and fast, a solution that eliminates potential wear of a locking pin or hole. At the same time, the connection is gap-free and very durable to give reliable operation in many harvest seasons.

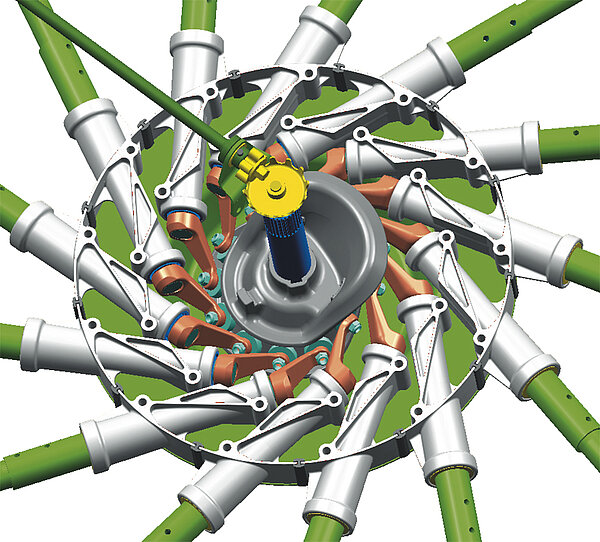

Each tine arm is controlled by its control shaft that is manufactured to precision-fit tolerances for exact fit in the control arm and precision tine control as the arm follows the cam track. It is this design that leads to those clean and lossfree rakes. Each tine arm is mounted on two ball bearings inside the hub plate. The two bearings are spaced wide for stable and smooth control of the shaft as well as reduced wear and higher work rates. The main part of the tine arm is the thick-walled and maintenance-free tube which is permanently and wear-free connected to the control shaft for reliable tine control without play. This is the secret behind optimum tine control and quality rakes.

For more than 10 years, the KRONE Lift Tine has convinced our customers around the world in terms of quality forage and rakes. Kinked in two positions, the vertical tine lifts the material clear off the ground. This is the secret behind producing clean forage in difficult conditions. The Lift Effect sees the grass moving up the length of the tine. Even extremely wet and heavy material will not bend the tines which are up to 10.5mm thick and are coiled around large-diameter arms for greatest stability and tidiest rakes.

An optimum rotor tilt across the direction of travel translates into minimal losses and boxy swaths. All Swadro rotors tilt as a standard feature. The lateral tilt controls the position of the tines relative to the ground and is set on the rear wheels of each rotor. In fact, the rotor should tilt slightly towards the swath in order to balance out the load the material puts on the tines. KRONE recommends a 1-2 cm tilt toward the swath.

The guide wheels on the bogies run very close to the tines for effective guidance and contouring. As the wheels cover a large surface area, the tines pick up every single blade without contacting the sward. Thanks to the equipment options adjusted to rake types, the rotor chassis can be individually equipped for any soil structure. The leading wheels are castering. Wider, larger-volume guide wheels for optimum soil protection on soft, boggy ground or two additional guide wheels per rotor for extremely uneven pastureland are just two of the choices available with the Swadro rotor chassis.

Strong coil springs transfer some of the weight to the main beam and the chassis as the rake is swathing along – for light treading on soft soils and clean rakes in any situation.

Standard on Swadro TC 930 and Swadro TC 1000, optional on the other Swadro models the rotors can also be lifted individually. This option brings advantages when swathing out wedges and when swathing along the edges of fields and meadows.

As standard, Swadro models from TC 880 onwards (TC 640 / TC 760 optional) are equipped with hydraulic width adjustment. The working width can be quickly and conveniently adjusted with precision from the tractor seat using the indicator scale on the outrigger.

Mechanical working width adjustment is standard on Swadro TC 640 and 760. The arms are extended and retracted to the required work/swath width by operating a crank.

Those who often use the rake in varying conditions will find it helpful to opt for the electric rotor height control system. This is installed as standard on all Swadro TC Plus. Control is conveniently operated from the tractor cabin via two electric motors which allow the rotor height to be adjusted easily and precisely while driving. Preselection is standard via the new KRONE PreSelect Digital preselection operation in conjunction with an ISOBUS-compatible terminal and a single-acting and double-acting control unit. Alternatively, the rotor height can also be adjusted using the KRONE PreSelect DS 50. In this case, only a power supply is required – an ISOBUS interface is not required.

All Swadro TC rotors have their work height adjusted down to the millimetre. This is done on a crank which is arranged on the outside of the rotor for easy access. A large scale helps operators to read the current position.

The transport height of the Swadro TC and TC Plus is less than 4 m after folding up the outrigger arms and retracting the width adjustment. This saves time, as neither tine arms (except on the Swadro TC 1000) nor guards need to be folded down for safe road transport.

If the wheels are fitted with slim tyres, it will be possible to expand the track width by 6 cm (2.4"). Simply refit a spacer tube on the wheel arms and move each axle out 3 cm (1.2").

The running gears of the Swadro TC rakes are fitted as standard with 10.0/75-15.3 tyres or, in the case of the Swadro TC 880, 930 and 1000, with 11.5/80-15.3/10 PR ( image on left). Swadro models from TC 680 onwards can be fitted with 15.0/55-17/10 PR tyres (image on right) for use on less load-bearing soils or on slopes. For both variants, the transport width is less than 3.00 m. Special AS tyres are available for the Swadro TC 640.

Swadro TC and TC Plus are attached to the two-point headstock by a ball bearing joint and a rod-steered undercarriage with articulated steering. This patented combination makes this KRONE rake a particularly nimble machine – Even on smaller and awkwardly cut areas, no crop is left lying around, as every corner of the field can easily be reached using the rotors without additional manoeuvring. On the Swadro TC 640, articulated steering is optional.

The high-clearance frame and the high rotor lift-out allow the machine to run over massive windrows without disturbing them.

For special applications in dry and light forage, the Swadro TC 680 and the Swadro TC 760 can be equipped in the centre with a six-arm fan rotor developed by KRONE. Hydraulically driven, it moves and aerates the entire crop which lies in the middle of the rake between the rotors. This promotes uniform wilting and boosts the quality of hay and leafy forage such as lucerne.

The Swadro TC 680 has a fixed 6.80 m work width, which makes it the ideal rake to work ahead of a compact round baler or forage wagon, producing swath widths that suit a narrower pick-up on a smaller harvester for optimum efficiency and cutting quality.

The two largest models in the twin-rotor rake centre delivery range offer a working width of up to 10.00 m. This means that forage harvesters and loading and forage transport wagons are also optimally utilised. A special feature of the Swadro TC 1000 is the spring relief, including single-rotor lifting mechanism, and the six-wheel chassis as standard equipment. The Swadro TC 1000 Plus has an eight-wheel chassis. The six-wheel or eight-wheel chassis optimally guides the 4.20 m large rotor diameter along the ground contours. The combination of this type of running gear and suspension system translates into thorough rakes and clean forage even on the high-capacity TC 1000 / TC 1000 Plus models.

The Swadro BaleTrain TC 880 Pro is designed so that the entire combination of rake, round baler and tractor complies with the legally permissible transport length in accordance with the German Road Traffic Licensing Regulations (StVZO). Thanks to the stable ball-head attachment 80, the tractor/trailer combination impresses with its smooth handling – even at higher speeds. At the same time, the compact design ensures good manoeuvrability, even on narrow access roads, in traffic or on the headland.

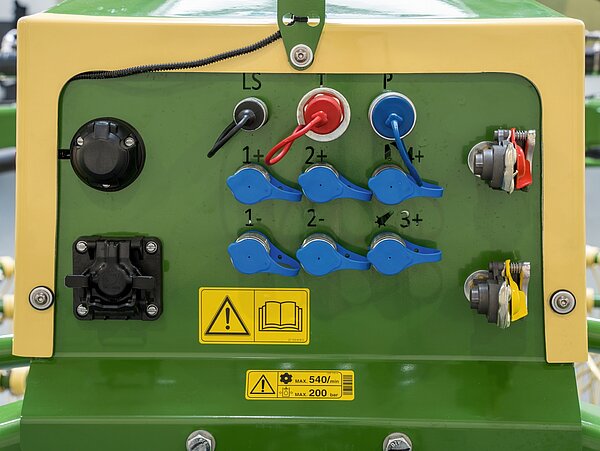

The Swadro BaleTrain TC 880 Pro is operated as standard via ISOBUS and Load Sensing. Alternatively, non-ISOBUS or Load Sensing-capable round balers can also be integrated without any problems: functions, such as pick-up and tailgate, can be controlled directly via the rake terminal. This is made possible by the control units on the rake – for maximum compatibility and operator comfort, even with older or simpler balers.

The Swadro BaleTrain TC 880 Pro features a double-acting and a single-acting control unit as standard which can be used, for example, to activate the pick-up of the mounted round baler. Optionally, the equipment can be expanded to include an additional double-acting control unit, for example for a hydraulic support jack, and an additional single-acting control unit for tailgate control. This provides all the required hydraulic functions – the round baler can be supplied entirely via the rake. Simple, well thought-out and practical.

All connections to the round baler, such as the ISOBUS connection, Load Sensing system, brake lines and control units, are routed through the main frame of the rake. The baler itself is attached via a bottom hitching with a K80 ball head. This means that the round baler can be connected quickly and easily.

A transfer gearbox on the Swadro BaleTrain TC 880 Pro ensures that both the rotors of the rake and the attached round baler are driven mechanically. While the baler runs constantly at 540 rpm, the rotors rotate at a reduced speed. An adjustment device on the gearbox allows two different rotor speeds to be set as well as an idling speed for the rotors. This allows the speed to be optimally adjusted to the harvesting conditions – or, if required, the round baler can be used on its own without having to separate the tractor/trailer combination.

If the steering angle of the mechanical forced steering is insufficient, the steering can be overridden at any time via the ISOBUS terminal. For this purpose, the steering features a small hydraulic cylinder. This is also used to implement the automatic steering function included in the AutoBale.

The KRONE Swadro BaleTrain TC 880 Pro is connected directly to the tractor using the ball-head attachment 80. This not only enables easy handling, but also ensures stable driving behaviour for the entire tractor/trailer combination. To ensure accurate tracking, the rake is also equipped with mechanical forced steering which is connected to the tractor via a ball-head attachment 50. This means that the tractor/trailer combination reliably follows the tractor's lane even through tight bends and narrow access roads.

With the KRONE Swadro BaleTrain TC 880 Pro, two essential steps in the forage harvesting process can be completed in one operation: swathing and baling. The specially designed rotary rake is designed for direct coupling to a KRONE round baler and has all the required connections for operation. This combination reduces travel distances, saves time and enables a consistently efficient harvesting process – especially in operations which focus on efficiency and process optimisation.

The KRONE AutoBale automatic functions significantly reduce the workload for the driver when operating the complex machine combination, consisting of tractor, rake and round baler. ISOBUS-compatible KRONE round balers offer a range of functions: 1. Automatic lifting mechanism tying cycle When this function is activated, the rake automatically lifts the rotors and the baler pick-up as soon as the tractor/trailer combination comes to a standstill and the baler starts the tying cycle. This prevents the rotor and pick-up from coming into contact with the ground when the machine is stationary. As soon as the finished bale has left the bale chamber, the rotor and pick-up are automatically lowered again and work can continue. In conjunction with TIM (Tractor Implement Management), the tractor/trailer combination also stops automatically – further reducing the driver's workload. 2. Automatic steering system Inhomogeneous crops may result in uneven swaths. In order to fill the bale chamber evenly, the round baler must be driven with a slight offset. The KRONE AutoBale automatic steering system processes the steering signals from the baler and actively controls the steering of the rake via the hydraulic cylinder in the steering rod. The result: stress-free driving and optimally formed bales – even in changing conditions. 3. Automatic reverse drive system Manoeuvring is often required, especially in small or winding areas. Thanks to the AutoBale reverse drive system, this is not only easier, but also safer: as soon as the system detects that reverse gear has been engaged, the rotors and pick-up of the rake are automatically raised. This prevents damage to the machine and sward – and manoeuvring is quick and stress-free.

KRONE AutoBale makes working with the Swadro BaleTrain TC 880 Pro significantly more convenient. The system supports the driver in operating the complex combination of machines, consisting of a rake and a round baler by automating central processes. The interaction between the machines is always precisely coordinated. Automatic control reduces operating effort, ensures uniform bales, prevents downtimes and increases efficiency – especially during long operations and in varying crop conditions.

The lifting delay of the front and rear rotors on the Swadro TC 1250 can be flexibly adjusted. On the standard model, this is done via a gear shifting gate on the front left rotor outrigger. On the Plus version, the delay can be adjusted via the terminal by entering the time directly. Optionally, the Swadro TC 1250 can be equipped with a single-rotor lifting mechanism for the front rotors to achieve a perfect raking result even on wedge-shaped spurs. On the Swadro TC 1250 Plus, all four rotors can be raised or lowered individually as standard. To ensure maximum flexibility in handling, both the Swadro TC 1250 and the Swadro TC 1250 Plus can be optionally equipped with a paired lifting mechanism. With an additional single-acting control unit, the front and rear rotors can be raised and lowered in pairs and independently of each other.

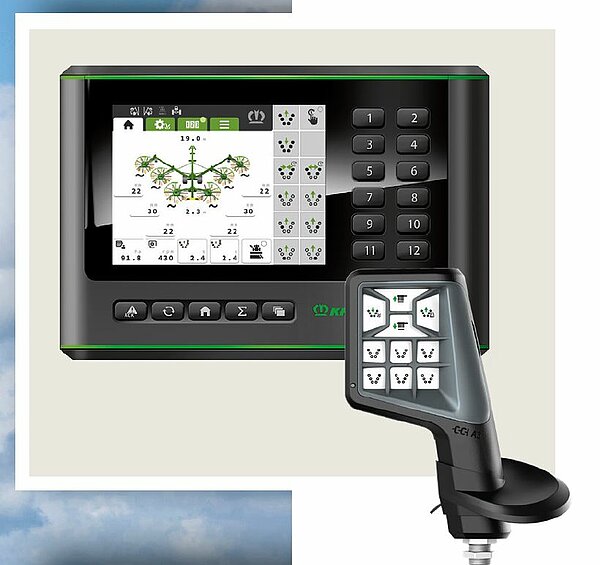

The Swadro TC 1250 is operated as standard via the new KRONE PreSelect Digital preselection operation device as well as a single- acting and a double-acting control unit. The desired function is preselected via an ISOBUS-compatible terminal. For greater convenience, the function preselection can be programmed on the tractor's control lever. If machines feature rotor height adjustment, functions can be preselected optionally via the KRONE DS 50 operation box. In this case, only a simple power supply is required and no ISOBUS interface to the tractor.

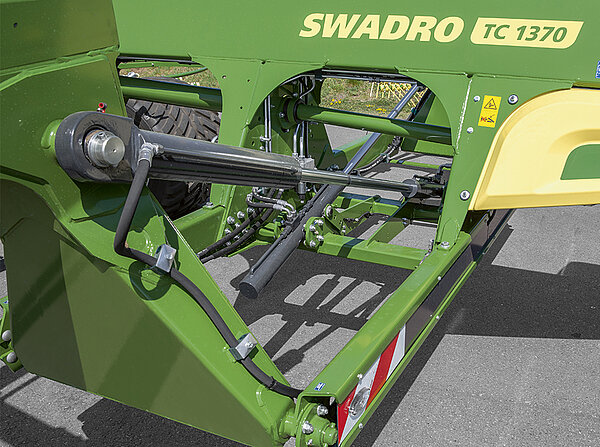

In work, strong coil springs shift the weight of the rear rotors to the main beam and the chassis, thereby taking load off the rear rotors. By comparison, the front rotors have hydraulic suspension which is set steplessly on the on-board spool chest by switching from lift-out to suspension and vice versa, This ensures clean swaths and the best forage quality by adjusting simply and conveniently to the respective soil conditions.

The transport wheels are clad with 500/50-17 tyres as a standard. The wider 620/40 R 22.5 tyres are available as an option and minimise the risk of soil compaction due to the larger contact area, especially on ground with little load-bearing capacity.

The compactly constructed rake can be easily and safely transported from one field to the next without folding down the tines thanks to a width of less than 3 m and a height of less than 4 m.

Swadro TC 1250 features a modern and appealing styling with a trapezium frame and massive tube steel arms that ensure high stability and longevity. The sloping panels keep the machine clean and country roads, too.

Using a hand crank attached to the rotor, the working height can be adjusted separately for each rotor of the Swadro TC 1250 with millimetre precision. The raking height can easily be read on a scale. This is even more convenient with the Swadro TC 1250 Plus. The working height can be adjusted electrically from the tractor via a terminal. The set raking height is displayed for each rotor on the terminal.

The TC 1250 with two-point headstock pivots in the lower links for smooth and stable rides on roads and in the field. Turning through a large angle, the headstock makes for tight headland turns and effective rakes in corners, a feature that saves valuable time in narrow harvest windows.

The working width and also the swath width are adjusted hydraulically as a standard feature for fast adaptation to varying conditions. The arms telescope rapidly to the correct working width – wide when gathering the last cut for presentation to the forager or narrow for the forage wagon and round baler.

The ISOBUS-compatible AUX joystick CCI A3 enables comfortable and fatigue-free operation of the Swadro TC 1370 Pro. In combination with a UT terminal on the tractor, it can be used, for example, directly on the armrest of the driver's seat.

Using the part-width Section Control, the rotors are automatically raised and lowered again individually, for example to avoid multiple processing when swathing wedge-shaped cut areas. This relieves the driver and therefore increases the acreage output by reducing turning times at the headland.

The operating structure of the Swadro TC 1370 combines clarity and convenience. Regardless of whether the tractor's ISOBUS terminal, the CCI 800, CCI 1200 ISOBUS terminals or the KRONE DS 500 are used, the entire machine can be set up on just two operating levels.

The Swadro TC 1370 is mounted as standard on the tractor via the pendulum-suspended two-point hitch. This allows the rake to adapt to lateral tractor movements while remaining extremely manoeuvrable. A ball-head attachment 80 for bottom hitching is available on request.

Thanks to the hydraulically lowerable main frame, the rake achieves a transport height of less than 4 m without having to fold down or remove the tine arms.

You can set and retrieve separate lift-out heights for the leading and rear rotors from the tractor terminal. More than that, you can set the lift-out height and also time the front and rear lift-out according to the prevailing conditions, This means that valuable working time is used efficiently.

The rakes that run on standard transport wheels have caster-steer bogies with pivoting wheels that are clad with 16x6.50-8 tyres. The rake can also take the wider 16x9.50-8 tyres on the bogies provided the tyres on the transport running gear are the optional 710/35 R 22.5 size. Both tyre sizes are also available for 6-wheel bogies with rear tandem axle.

620/40 R 22.5 transport tyres are standard specification. But you can also opt for hydraulic brakes and wider 710/35 R 22.5 tyres to improve the performance in boggy terrain. Both tyre sizes are small enough to ensure that the 40 km/h machine doesn’t exceed the statutory 3 m transport width.

The operator controls the work height from the terminal so there is no need to dismount the tractor. You can either adjust all rotors at the same time or each rotor separately. Also, you can program two different heights to the system and retrieve them later by fingertip control.

The hydraulic rotor suspension that is integrated in the lifting cylinders provides gentle treading also in difficult conditions. The system is set up steplessly and conveniently from the tractor and separately for the leading and rear rotors. The new and integral Soft-Down drop rate control lowers the rotors particularly softly into work – a boon for the quality of feed.

The swath width is adjusted irrespective of the work width by varying the distance between the two rear rotors between 1.40 m and 2.60 m. As another key feature, the tine arms on the rear rotors have five double tines which optimize the work and quality for the following harvester.

Telescoping hydraulic arms adjust the positions of the two leading rotors left and right separately. This way, the rake can vary its working width from 10.80 m to 13.70 m to adapt to varying field conditions. The rotors resume their previous positions automatically when lowering into work.

Using the part-width Section Control, the rotors are automatically raised and lowered again individually. Thanks to the fully automatic control via GPS position, multiple processing or overrunning can be avoided, for example, when swathing wedge-shaped cut areas or at the headland. This relieves the driver and therefore increases the acreage output thanks to shorter turning times at the headland.

Operation of the Swadro TC 1570 stands for clarity and comfort. This applies to the use of the tractor's own ISOBUS terminal and, in particular, to the optionally available DS 500, CCI 800 or CCI 1200 ISOBUS terminals which can be used to adjust the entire machine via just two operating levels. On request, these terminals can be combined with an ISOBUS-compatible CCI A3 joystick which enables even more comfortable and fatigue-free operation.

The Swadro TC 1570 is not only equipped to the maximum in terms of working width – the transport chassis has 710/40 R 22.5 tyres as standard. The optional 800/35 R 22.5 tyres provide even more contact patch. Together with the wide tyres of the four-wheel rotor chassis (optional six-wheel rotor chassis) and the additional support wheels on the two outriggers, a perfect combination of driving stability and ground-protecting work is formed.

Using the Soft-Down automatic lowering mechanism, the rotors are lowered very gently via automatic pressure regulation; this protects the sward and increases forage quality. The integrated vibration damping prevents the machine from rocking when driving over uneven ground or swaths on the headland.

According to the motto "as low as possible, as high as necessary", the lifting heights of the rotors at the headland can be adjusted to the field conditions via the operating terminal. Likewise from the cab, the lifting delay of the rear to the front rotors can be adjusted to the needs of the driver. You can choose between a time-dependent or path-dependent delay. Turning times are minimised and the acreage output is increased.

The Swadro TC 1570 is equipped with a pendulum-suspended two-point headstock Cat. ll/lll. This reliably compensates for uneven ground and gives the machine enormous manoeuvrability thanks to its large steering lock. Thanks to the hydraulically lowerable main frame, the machine can be brought to less than 4 m transport height without having to fold down tine arms or guards. In the working position, the raised main frame ensures reliable forage flow inside the machine, even with large forage masses.

For optimum adaptation to different field and forage conditions, the raking height can be adjusted electrically from the cab via the operating terminal. It is possible to adjust the height of each rotor individually or all rotors simultaneously. In addition, two self-selectable heights can be stored on the terminal and controlled at the touch of a button.

Hydraulic rotor relief integrated in the lifting cylinders allows the bearing pressure to be adjusted separately for the front and rear rotors at any time. This is done simply and conveniently on the terminal by entering a value directly or by selecting one of the two freely assignable memories. When adjusting the working or swath width, the pressure is automatically adjusted by active control so that the rotors are always evenly relieved. This ensures an intact sward and clean forage under all conditions!

15 tine arms per rotor and 5 tines per tine arm on each of the rear rotors enable loss-free forage intake even at high driving speeds. Thanks to the hydraulically adjustable outrigger arms of the rear rotors, swaths can be produced which have a width of between 1.20 m and 2.70 m. This means that the downstream harvesting machines, whether baler, loading and forage transport wagon or harvester, can be optimally utilised.

The two outriggers of the V-frame are each supported by a front support wheel. As a result, the machine is characterised by a previously unattainable quiet running in the field and especially during turning manoeuvres in the headland position, even at higher driving speeds. The result: maximum acreage output and maximum efficiency.

The KRONE Swadro TC 1570 sets new standards – because the proven V-frame concept of the Swadro TC 2000 is now also represented in the four-rotor rake segment. The unique concept gives the Swadro TC 1570 a maximum working width of 15.70 metres. To respond flexibly to different harvesting conditions, the working width can easily be varied using the separately movable outriggers. This means you always achieve the desired swath volume.

The extra hydraulic steering system will be appreciated by those who seek tighter turns to manage narrow gates and by those who do a lot of countersteering in sloping fields. A hydraulic cylinder on the steering linkage adjusts the turn angle or ride behind the tractor.

The Ackerman steering system on the transport chassis can be operated in two ways: either passively via a linkage or actively via a hydraulic ram. Excellent castering, manoeuvring in tightest space and easy steering are the qualities that make this chassis stand out from everything else.

Running on big 800/45 R 26.5 tyres for good road stability, the transport chassis is approved for road travel at 40 km/h In addition, the ground pressure is kept low and the sward is sustainably protected.

The Swadro TC 2000 is pulled over the lower links of the tractor. The movable headstock Cat. II/III compensates for uneven ground. The stable support jack ensures a high degree of stability when parking.

The extra cylinder on the steering linkage helps manage narrow field and farm gates and clear awkward patches. This means that even the smallest field entrance can be mastered without manoeuvring.

The steered axle is activated automatically when the rotors are being lifted out of work. At this moment the chassis is steered via a rod – a detail that ensures maximum agility in headland turns and cuts turn-around times.

The axle on the transport chassis is switched off during work This feature ensures uniform and straight swaths that keep the following harvester happy.

The use of the automatic part-width Section Control reduces the driver's workload considerably, especially when swathing wedge-shaped areas. It detects areas which have already been worked and automatically raises the rotors, thereby preventing the same area from being worked twice. This optimally relieves the driver and allows him to fully exploit the performance potential of the Swadro TC 2000, even on long days.

With the CCI 800 and CCI 1200 operating terminals, KRONE offers two ISOBUS-compatible touchscreen terminals with an 8" or 12" colour display. In addition to the main screen, up to two other screens can be displayed alternately. For example, it is possible to switch between the assignment of the joystick, the Section Control function or a camera image while working.

The compact DS 500 terminal has a 5.7" colour display. Operation is either via the twelve function keys or via touchscreen according to the driver's needs. Using the optional ISOBUS joysticks makes operation even more convenient. This relieves the driver in the best possible way, even on long working days.

The automatic folding feature: A hydraulic sequence control manages the individual steps, taking off stress and strain from the operator.

Not only is it possible to adjust the working widths to needs but also to adapt the swath width. This is done by adjusting the rear rotors hydraulically and steplessly between 1.60 m and 2.80 m which is preset on the terminal. The technology helps form perfectly boxy and high-volume swaths for round balers and forage wagons.

The rake can vary its work width between 10.00 m and 19.00 m hydraulically, producing swaths that match the capacities of the following harvesters. To do that, the two arms extend and retract on a sliding carriage so the two rotors in the pair will always rake up the same amount of material, producing uniform and consistent swaths that suit exactly the capacity of the following harvester.

The right model for every field of use

| Swadro TC 640 | Swadro TC 680 | Swadro TC 760 | Swadro TC 880 | Swadro TC 930 | Swadro TC 1000 | Swadro TC 1250 | Swadro TC 1370 | Swadro TC 2000 | Swadro TC 1570 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | twin rotor centre delivery rakes | twin rotor centre delivery rakes | twin rotor centre delivery rakes | twin rotor centre delivery rakes | twin rotor centre delivery rakes | twin rotor centre delivery rakes | four-rotor rakes | four-rotor rakes | six-rotor rakes | four-rotor rakes |

configure

|

| Tractor attachment | pulled | pulled | pulled | pulled | pulled | pulled | pulled | pulled | pulled | pulled |

configure

|

| Swath width (m) | 1.00 - 1.70 | 1.00 | 1.00 - 1.80 | 1.30 - 2.50 | 1.30 - 2.50 | 1.30 - 2.50 | 1.40 - 2.20 | 1.40 - 2.60 | 1.60 - 2.80 | 1.20 - 2.70 |

configure

|

| Work width (m) | 5.70 - 6.40 | 6.80 | 6.80 - 7.60 | 7.60 - 8.80 | 8.10 - 9.30 | 8.90 - 10.00 | 9.80 - 12.50 | 10.80 - 13.70 | 10.00 - 19.00 | 11.00 - 15.70 |

configure

|

| Rotor diameter (m) | 2.70 | 3.30 | 3.30 | 3.60 | 3.80 | 4.20 | 3.30 | 3.60 | 3.30 | 3.80 |

configure

|

| No. of tine arms per rotor | 2 x 10 | 2 x 10 | 2 x 13 | 2 x 13 | 2 x 15 | 2 x 15 | 2 x 11 / 2 x 13 | 4 x 13 | 4 x 13 / 2 x 15 | 4 x 15 |

configure

|

| Power requirement kW/hp | 22 / 35 | 37 / 50 | 37 / 50 | 40 / 55 | 51 / 70 | 51 / 70 | 59 / 80 | 59 / 80 | 96 / 130 | 81 / 110 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)