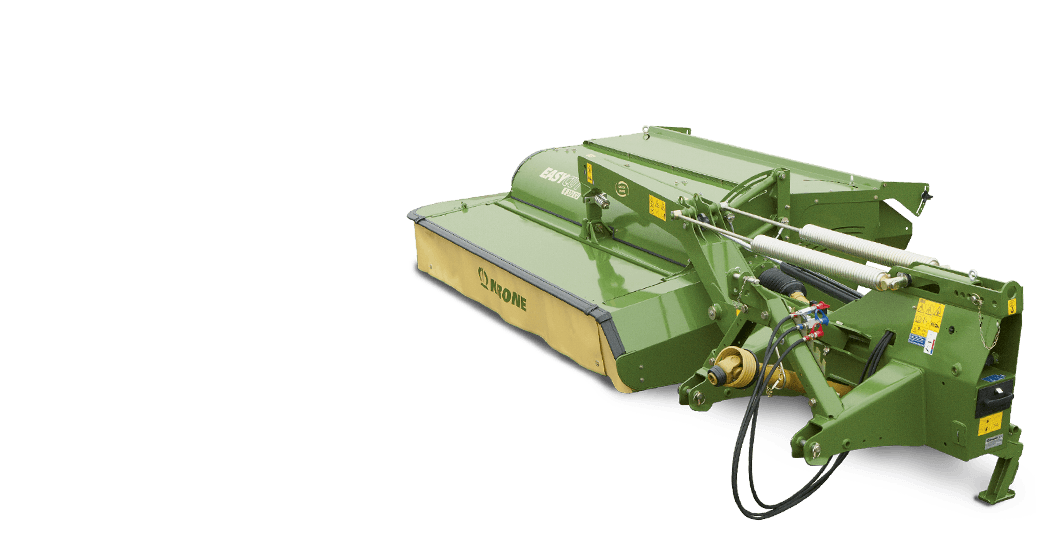

Healthy cows and a high milk yield: Two demanding goals which can only be achieved if the quality of the basic forage is right. The EasyCut mowers from KRONE provide the basis for a successful harvest. Clean, efficient and user-friendly – KRONE EasyCut.

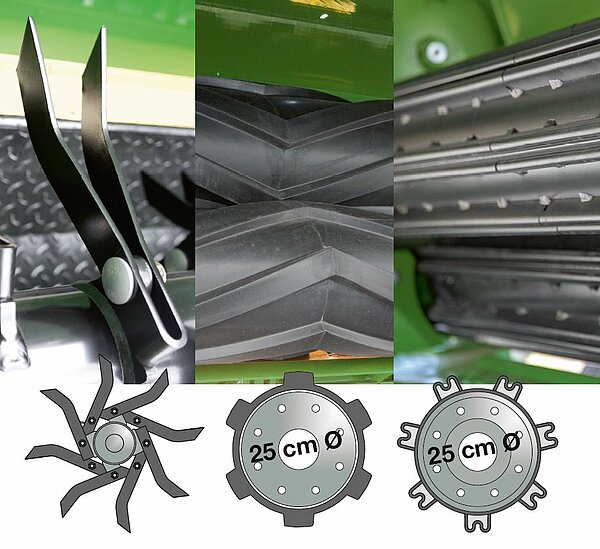

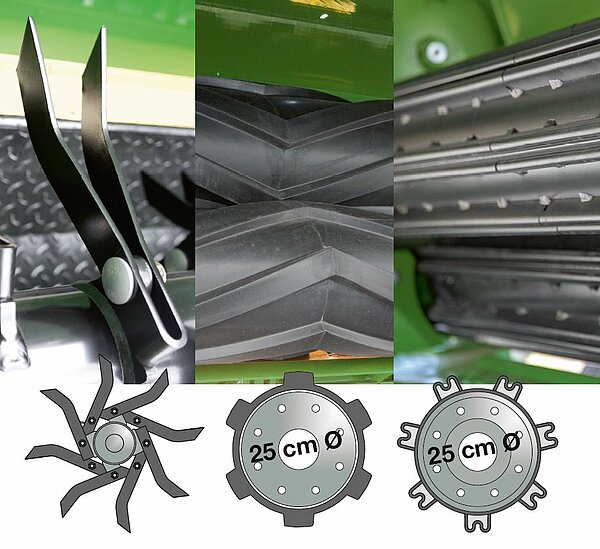

- Conditioner – CV models with V-shaped steel tines, CR models with polyurethane rollers or M-Rolls

- SmartCut – Stripe-free swath with optimum overlap of the blade tracks

- Quick-change blades for quick blade handling

- SafeCut – Individually secured cutting discs

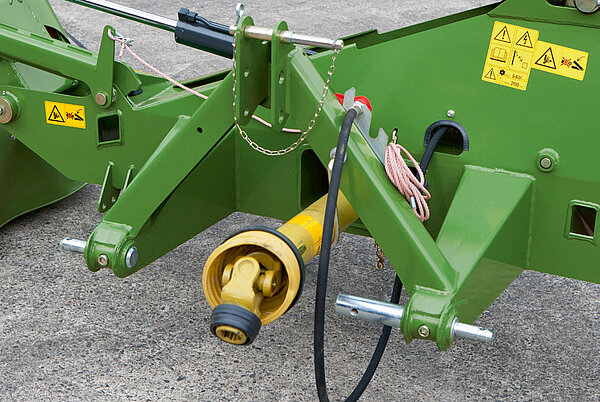

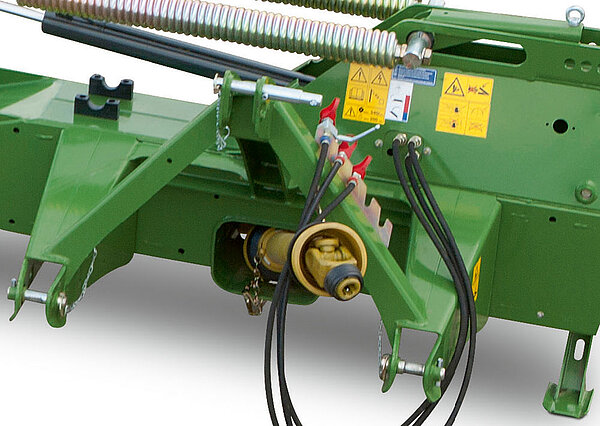

- DuoGrip – Centre of gravity mounting with dual guidance

The tine conditioner models

EasyCut R 280 CV und R 320 CV

The KRONE CV rotor with V-shaped and grippy steel tines spreads the crop at the full working width. Its massive 64 cm diameter and the helical arrangement of the tines warrant a continuous crop flow, high throughputs and superior conditioning.

Product features

Two counter-rotating steel rollers ensure uniform conditioning of e.g. lucerne. The M-profiles on the rollers intensively bend the crops and therefore enable a homogeneous drying process without leaf loss.

Those who seek faster wilting can opt for a tine or roller conditioner on the rear-mounted units Both condition the mown crop stalks over the entire working width.

KRONE offers a wide range of conditioners that suit all crops and needs. The CV steel tine conditioner is the conditioner of choice when intensive treatment is required in grass and haulm crops. A CR conditioner can be used to condition clover and lucerne more gently. Here you can choose between polyurethane rollers or M-Rolls.

With working widths from 2.73 m to 4.50 m, the EasyCut R series rear mounted |mowers delivera clean mowing pattern. The compactly mounted mowers are low drag resistance and adjust perfectly to all ground contours.

The new three-point hitch with optional hydraulic adjustment of the bearing pressure stands for maximum comfort and perfect work.

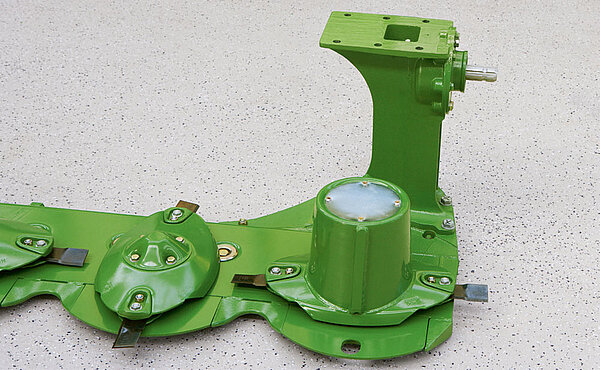

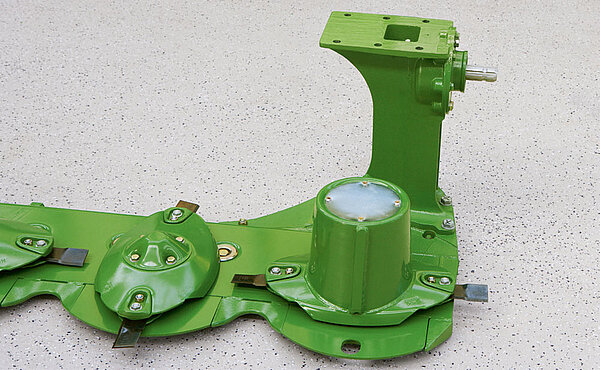

The all-round welded, enclosed cutterbar is maintenance-free and remains reliably sealed and dimensionally stable even after many years of use. Special cleaning processes during production enable lubrication for life and make the usual oil change superfluous.

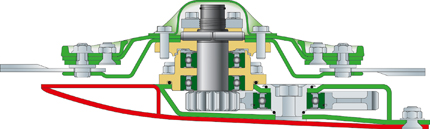

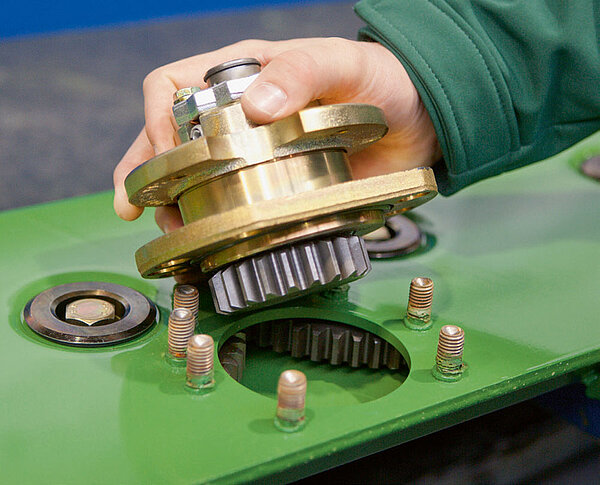

The KRONE developed satellite driveline comprises massive spur gears with up to 66 teeth which transfer the power all the way down to the very last disc. The large-diameter gears rotate at reduced speeds, with a higher number of teeth meshing with the neighbouring gearwheels for even quieter running, ultimate efficiency and maximum longenity. The auxiliary gears drive one disc each and as a result are exposed to only minimum loading.

The cutterbar is driven by the right-angle gearbox just behind the inner top hat This ensures blockage-free work on the headland or in crops which run out in a wedge shape.

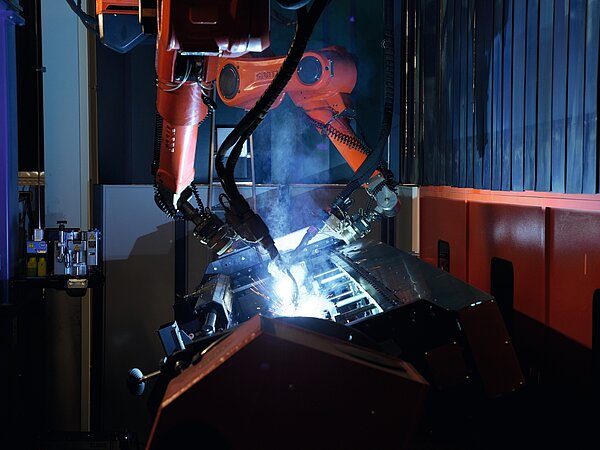

As the central element of every disc mower, the cutterbar is a particular focus at KRONE: Welded all round and lubricated for life, it is manufactured using the latest welding robot and CNC technology – for maximum precision, maximum durability and the highest quality standards.

The wedge-shaped cutterbar offers many height setting options. The spur gears run in massive double bearings, allowing the cutterbar to handle extremely high loads.

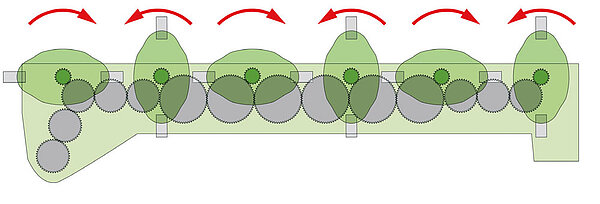

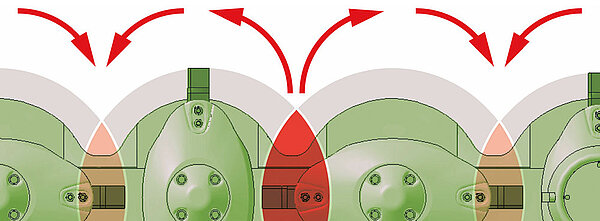

With discs spinning in the B sense of rotation, EasyCut spreads the material across the full cutting width. All discs turn in pairs, spreading the material across the working width for faster and more uniform wilting.

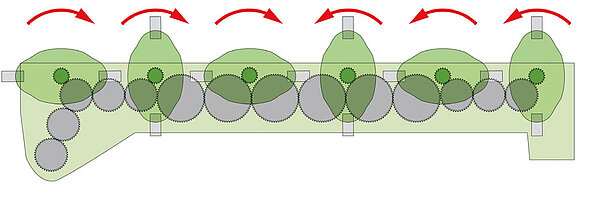

Spinning inwards, the discs feed the material to the middle of the machine to avoid tractor wheels running over the cut crops. The EasyCut R 280 and R 320, with direction of rotation A, form one swath. With discs spinning in the A sense of rotation, EasyCut R 360 and R 400 form two swaths.

The spur gears are arranged in a forward position and eccentrically inside the gearbox right under the discs. The small auxiliary spur gears are removed from above, the massive main gears gearbox from the side.

With some discs turning in pairs towards each other and others turning away from each other, it was necessary to redesign the degree of blade overlap to ensure cleanest cuts. For stripeless cuts in light and young crops, we have therefore increased blade overlaps on the discs turning outwards (SmartCut). The greater distance between the blades run- ning to the rear favours the discharge of large quantities of forage.

Worn blade fixing pins and wear parts are not an issue for KRONE EasyCut, because the modular design of the discs allows you to replace them individually. If required, the blade fixing pins can be replaced with blade screws.

|112 mm long blades in a set shape and the wide overlap of the blade tracks ensure a clean cut and uniform forage flow.

The blades are free to spin 360-deg. on their bins. The blades are protected, cannot get wedged, wear less and are self-cleaning

We welded curved stops between the individual skids that protect the cutter- bar from damage and also contoured the underside of the stops in such a way that no material can build up here The mown crop is discharged continuously.

With high-cut skids for stubble lengths of over 80 mm, you mow 30 or 50 mm higher, depending on the assembly, which is ideal in forage and whole crop silage.

Made from hardened steel, the extra wide skids reduce the ground pressure and hence offer effective protection of both the cutterbar and the sward. The skids are bolted to the cutterbar so they are easy to replace.

Quick-change blades are a must for many farmers and contractors. These blades are quick and easy to reverse or replace in situ.

If the system is suddenly overloaded, the impact is not directed to the spur gears in the driveline, instead a roll pin in the sprocket drive shaft shears off. The pinion shaft continues spinning, jacking up the disc in question, moving it out of the risk zone and the orbit of the neighbouring discs. As a result, SafeCut prevents damage to the spur gears and the neighbouring discs. The roll pins can be replaced in just a few minutes and costs very little.

Each disc on the mower has its own individual impact protection. When the blade hits an obstacle the shockload is transferred to a roll pin which breaks. The cutting disc then rotates upwards by 15 mm via the thread on the drive shaft.

There is no load on the roll pins during oper- ation. The bearing is tensioned by a nut and two clamping screws. As a result, the roll pins do not suffer from material fatigue and even after many hours of operation they will break only at their inbuilt load level - even after many hours of use.

Orbiting within the sphere of the mower bed and never protruding beyond the skids, the EasyCut discs benefit from two-fold protection. Additional protection comes from the standard SafeCut system.

Maintaining a uniform pressure across the entire work width is a requirement that is thoroughly met by Krone disc mowers, courtesy of the gearbox that is arranged on the inside of the machine where it shifts the centre of gravity to the side. In conjunction with the short outrigger arm and guidance via additional suspension arms, this ensures maximum stability with low weight - ideal for tough, practical use.

The mower is mounted on a pin which pivots in a ball bearing at the end of the outrigger arm. This design provides plenty of movement and exemplary contouring. In addition, lan limpact darrage protection system is integrated as standard.

The parallelogram linkage absorbs lateral forces and guides the unit in direction of travel. At the same time, it helps reduce the load on the jib and the suspension system in the machine’s centre of gravity. The two rods also indicate to the operator whether the tractor linkage is at good height.

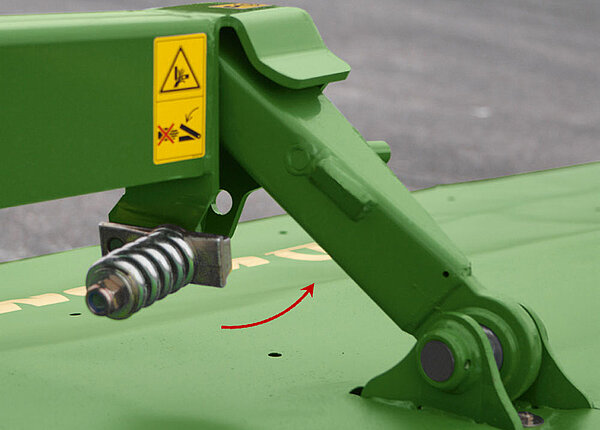

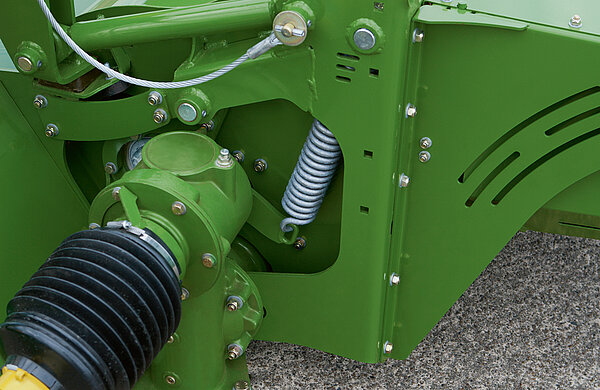

The standard mechanical impact protection system is a very dependable system that consists of an adjustable coil spring and a latch. It is integrated into the suspension of the mower unit and therefore ensures that the mower unit avoids hittng an obstacle.

The standard impact damage protection system on EasyCut R models gives you peace of mind as you work along borders, fences and hedges and suddenly collide with an obstacle. When the system trips, the mower swings backwards by up to 1.20 m land upwards by up to 40 cm. and clear out of any obstacle. After passing the obstacle, the mower automatically swings back to the working position.

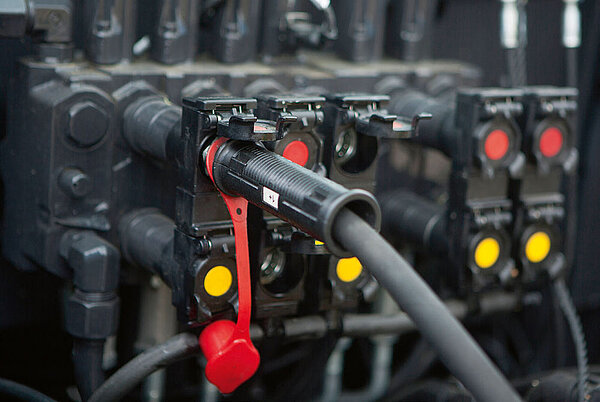

The spring can also be adjusted hydraulically as an option for instant ground pressure changes on the move. To disconnect the mower, the spring tension is released from the tractor seat.

Adjusting the spring manually is a fast and easy job. Simply refit a pin to select the target tension. As the spring tension increases, the bearing pressure decreases.

Conveniently visible from the cab, the pressure gauge indicates the current ground pressure In this way, you can be sure that you are working with optimal settings, with minimal side pull and significantly lower power requirements.

Shifting the machine weight to the middle distributes its weight more evenly on to the lower links, which improves the tractor ride In add tion, you have a clear viewto the rear with the outside rear-view mirrors.

The Z-shaped arm has a low pivot point for a reduced transport height Due to the high ground clearance, even rutted roads can be driven over easily-

Z-shaped arms enable large vertical travel (29° up, 20° down) Nothing stands in the way, ideal prerequisites for working on slopes, embankments and ditches.

The unit folds hydraulically beyond TDC, the single-acting ram on the EasyCut R 280 and R 320 has an accumulator and folds 110° over top dead centre, the double-acting ram on EasyCut R 280 CV, R 320 CV and R 360 folds 124° for better road stability and visibility. Both versions are active in both directions and guarantee trouble-free folding.

All EasyCut R 280 and EasyCut R 320 models have a cartilevered deck that enables an unobstructed crop flow. These mowers cut and swath across sloping fields and in awkward patches without any hiccups, The uniform swathing is impressive.

The fold-up ends of the curtain are lined by bumper tubes that protect the curtain from damage when the machine hits an obstacle.

EasyCut R 280 and EasyCut R 320 have adjustable lower link pins that allow the machine to run offset behind the tractor This ensures the full working width with different tractor track widths, on slopes and in combination with the front mounted mower.

The power flows down a frictional driveline of shafts and gears. The freewheel and friction disc clutch on the uni- versal shaft between the main gearbox and the mower protect the cutterbar, universal joints and the tractor's PTO drive.

To relieve the cutterbar, the EasyCut R 280 and EasyCut R 320 have a manually or optionally hydraulically adjusta- ble tension spring. This means that the cutterbar adjusts itself perfectly to all ground irregularities, even when driv- ing fast.

The vertical storage position saves space in the machine shed. The optional stands give the machine good footing and are useful for attachment and removal. Of course, the Easy Cut R 28D and EasyCut R 320 can also be parked in the folded-down position.

A single-acting hydraulic cylinder with accumu lator is all that is required to swivel the EasyCut R 280 and EasyCut R 320 rear mounted mowers from the working to the headland or transport position and vice versa.

Spare blades are neatly stored in this mobile drawer, neatly stored in this mobile drawer which eliminates clutter in the cab.

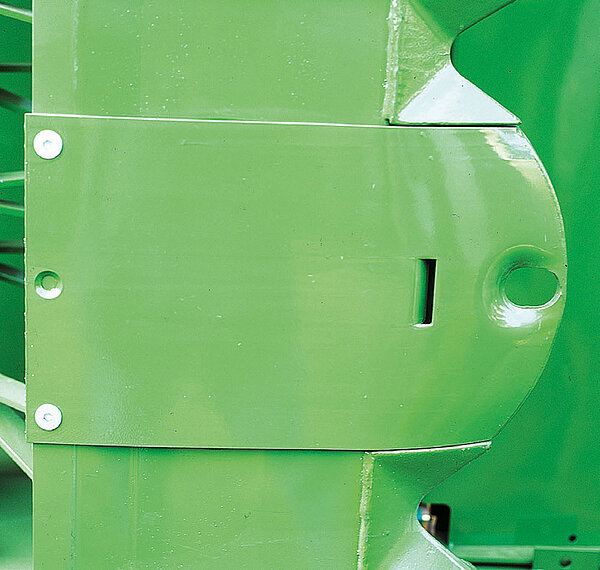

The curtain folds up for cleaning and replacing the blades - to give convenient access to the discs for easy cleaning and blade replacement.

When the mower moves into transport position, the guard folds back to reduce the transport height. When the machines lowers into work position the guard, too, moves back into work position.

These two mowers have two very strong suspension springs that minimize the ground pressure. To adjust to different operating conditions, the spring tension can be varied manually or optionally hydraulically from the tractor seat.

These two models have particularly strong headstocks. To adjust to different tractor track widths and for use together with front mounted mowers, they can be moved sideways or the lower link pins can be offset.

The discs on the EasyCut R 360 and R 400 models work in pairs, with two discs running with opposed action spreading the material across the full width. Forming two swaths (A sense of rotation): This is an option for those who try to avoid running over the cut crops. The cutting discs rotate in opposite directions only in the centre, producing two swaths.

Spreading the material leads to faster wilting because it exposes a larger surface to the sun and wind, leading to very high-quality forage and fewer losses.

The EasyCut R 400 moves hydraulically into the transport position behind the tractor and folds up the front curtain. This turns the machine into a narrow, low-profile transport unit for smooth passage underneath bridges and through gates and for safe travel on public roads.

The EasyCut R 360 model swings up and beyond TDC Its position in the centre and close behind the tractor increases driving comfort especially on smaller tractors.

900 rpm for intensive, 600 rpm for less intensive conditioning. The required conditioner speed can be set quickly and easily using the actuating lever.

This lever in the multi-step gate varies the gap between the tines and the baffle plate. As the gap decreases, the degree of conditioning increases.

The optional hydraulic swath flap ensures a clean harvest along field edges, ditches, forest edges and hedges, preventing loss of forage along the edges and ensuring quality. Only an additional double-acting hydraulic connection has to be installed. The stepless setting of the swath flap enables optimum adjustment of the spreading width

The tine conditioners on each mower span across the work width from the left to the right top hat, providing a uniform and consistent crop flow across the full width and giving optimum conditioning.

The hardened, V-shaped steel tines on grip work intensively and are extremely powerful. The tines pivot to the rear when hitting a foreign object The limited pendulum travel towards the front increases the lifetime of the bolts.

The counter-rotating rollers engage with each other and therefore exert a squeezing movement on the crops. and yet leave a sufficiently wide gap for the material to pass through. The result: uniform, intensive conditioning for homogeneous drying processes without rolling losses; ideal e.g. for salvaging lucerne.

Double power: The top roll of the M-Rolls is driven by a separate gearbox on the right end of the cutterbar which synchronizes the speed of the top and bottom rolls, This means you are well equipped even in the heaviest forage crops.

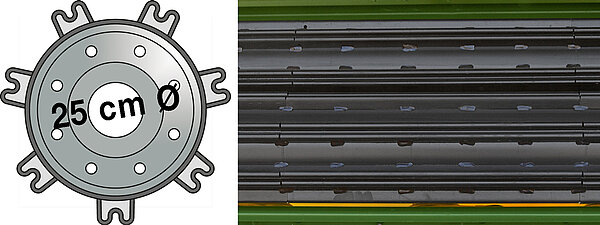

250 mm diameter: The large-diameter CR conditioner rotors deliver a smooth and consistent flow of crop and have a low power input.

The full-width polyurethane rollers ensure a uniform conditioning effect across the entire work width and the polyurethane coating ensures maximum longevity. The interlocking surfaces of the rollers This intermeshing results in intensive, yet gentle conditioning of the crops without leaf loss.

The conditioning rollers are driven by gearboxes. The box that drives the bottom roller is integrated in the gearbox that powers the cutterbar. The top roller suspends from a spring which ensures a continuous flow in inconsistent growth and allows foreign objects to pass the system trouble-free. To adjust to different forage quantities and types, the roller distance and contact pressure are infinitely variable.

The headstock can move to either side The adjustment to different tractor track widths and front mounted mowers enables mowing at full working width and with optimum overlap.

Stands are available as an option to store the machine either in work or transport position - This saves space = ideal for overwintering indoors.

To prevent collision damage, the folding front and side guards have rubber protective edges all around.

The curtain folds up to give easy access to the discs for cleaning and convenient blade replacement - a compact design that offers superb accessibility.

Two suspension springs transfer the weight of the mower to the headstock reducing the ground pressure and protecting the sward. Optionally, the tension springs can be pretensioned hydraulically from the tractor seat - for even greater operator comfort.

The stable construction and easy handling of the robust support jack guarantees that the machine can be safely parked in the parking position.

The integrated pendulum stop cylinder stabilises the EasyCut R 450 in the headland position. In doing so, the pendulum stop cylinder pulls the mower unit onto the outrigger arm, resuting in maximum headland lift and smooth driving behaviour even on uneven ground concitions and when performing fast turning manoeuvres.

The standard hydraulic impact damage protection system of the EasyCut R 450 enables safe working along field edges and in the event of unexpected obstacles. If contact is made with an obstacle, the rapid traverse valve causes the mower unit to swivel backwards and upwards by up to 2.50 m, thereby preventing any damage.

Thanks to the patented DuoGrip centre of gravity suspension, the EasyCut R 450 ensures an even supporting surface across the entire working width. The hydraulic relief enables precise adjustment of the bearing pressure, while a pressure gauge indicates the preset value. This guarantees optimum ground tracking and a flawless cutting pattern.

Thanks to the new tensioned guard cloth design and a wide-opening front guard, the EasyCut R 450 offers significantly improved accessibility. Equipped as standard with the quick blade change system and a spare blade drawer, nothing prevents you from changing blades quickly.

The EasyCut R 450 not only impresses with maximum performance in the field, but also with maximum safety on the road. Equipped with high-visibility warning panels and a robust LED lighting system, the machine is clearly visible from all sides.

Thanks to an optional additional double-acting control unit, the bearing pressure can be conveniently and precisely adjusted from the tractor cabin. This allows the driver to quickly adjust the mower to changing conditions without getting out of the tractor.

For road transport, the EasyCut R 450 is swivelled into a rearward transport position, resulting in a transport width of less than 2.50 m. The counterweight automatically retracts by 60 cm to reduce the overall width of the machine, thereby making transport on roads and narrow lanes considerably easier..

The adaptability of the EasyCut R 450 to the front-mounted mowers offers decisive advantages. Thanks to the flexible adjustment of the overcut, even slopes or sharp bends can be cleanly mowed. Seamless integration with KRONE front-mounted mowers improves the overall performance of the combination and increases acreage output.

Thanks to the hydraulically telescoping KRONE EasyBalance counterweights on the left side of the EasyCut R 450, which can be optionally extended to up to 10 plates of 50 kg each, driving stability is improved and the load on the tractor is reduced. The weights automatically support the right tractor lower link when swivelling the mower unit, thereby keeping the mower stable even when loaded on one side and allowing it to work reliably, even in difficult conditions such as uneven terrain.

The right model for every field of use

| EasyCut R 280 | EasyCut R 320 | EasyCut R 360 | EasyCut R 400 | EasyCut R 450 | EasyCut R 280 CV | EasyCut R 280 CR | EasyCut R 320 CV | EasyCut R 320 CR | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Work width (m) | 2.73 | 3.16 | 3.60 | 4.04 | 4.50 | 2.73 | 2.73 | 3.16 | 3.16 |

configure

|

| Transport height (m) | 3.50 | 3.90 | 4.00 | 1.50 | 1.50 | 3.10 | 3.10 | 3.50 | 3.50 |

configure

|

| No. of discs | 4 | 5 | 6 | 7 | 8 | 4 | 4 | 5 | 5 |

configure

|

| No. of top hats | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

configure

|

| Conditioner | - | - | - | - | - | series | - | series | - |

configure

|

| CR conditioner with rubber rollers | - | - | - | - | - | - | series | - | series |

configure

|

| CR conditioner with M-Rolls (steel rollers) | - | - | - | - | - | - | optional | - | optional |

configure

|

| Power requirement kW/hp | 40 / 55 | 50 / 68 | 55 / 75 | 66 / 90 | 74 / 100 | 51 / 70 | 51 / 70 | 59 / 80 | 59 / 80 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)

![[Translate to EN:]](/fileadmin/_processed_/3/6/csm_DJI_0618_179772_3f60d7ea3b.jpg)

![[Translate to EN:]](/fileadmin/_processed_/5/7/csm_DJI_20250428153242_0067_D_AK_277757_2882066025.jpg)

![[Translate to EN:]](/fileadmin/_processed_/b/8/csm_A001C1208_240428_PF13_250742_abb6652363.jpg)