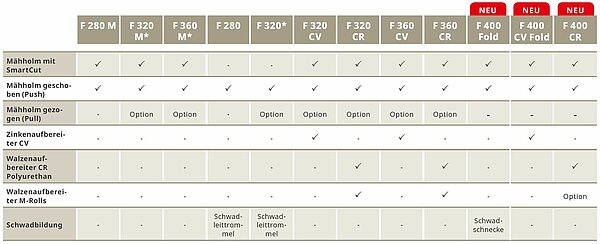

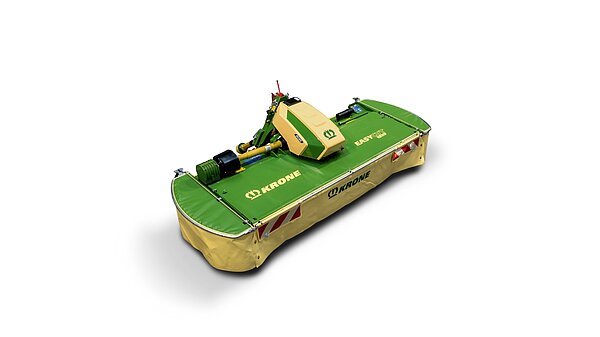

The EasyCut F series comprises innovative front mounted mowers with working widths from 2.71 m to 4.04 m – optionally with tine or roller conditioners. Thanks to the choice of Push, Pull or Plus headstocks, the machines offer maximum flexibility for a wide range of operating conditions. Actively driven swath drums prevent the forage from being driven over and therefore ensure clean pick-up and the best forage quality.

NEW: The fourth generation of the EasyCut F 320 and F 360

Agritechnica 2025

With the fourth generation of the EasyCut F 320 and F 360, KRONE presents two new front mounted mowers without conditioners that can be customised thanks to the modular design and three attachment options to meet individual operational requirements.

Read the news

Product features

The front mounted mowers with conditioner are able to swath the material or spread it across the work width. These models are designed for contractors and professional farmers and make a great combination with three-point-mounted rear mowers or butterfly mowers. Rounding off the EasyCut F series, the four-metre front mounted mowers with conditioner or merger auger are the perfectly complement your harvesting machinery for maximum efficiency in the field.

With three choices of headstocks – Push, Pull and Plus – the front mounted mowers can be flexibly adapted to a wide range of application requirements. Working widths of 3.16 m or 3.60 m and the optionally available merger auger allow customised equipment – tailored to the respective centre of gravity.

These front mounted mowers offer working widths of 2.71 m to 3.16 m and have powered swath drums that form narrow swaths so the tractor can straddle them. The focus is on quality forage.

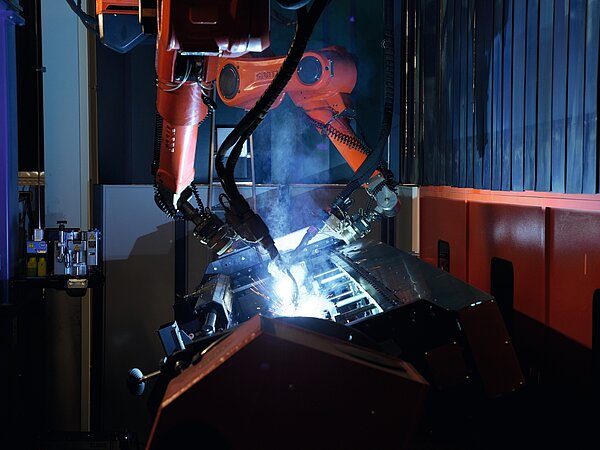

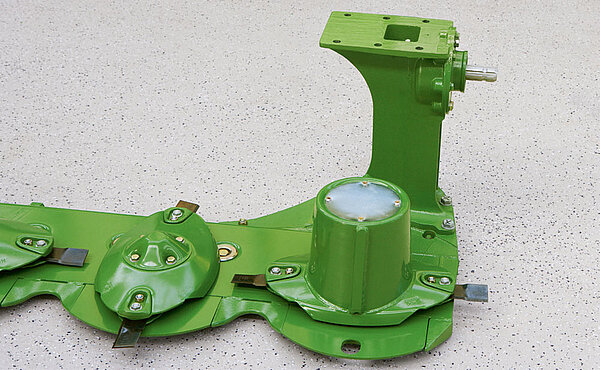

The all-round welded, enclosed cutterbar is maintenance-free and remains reliably sealed and dimensionally stable even after many years of use. Special cleaning processes during production enable lubrication for life and make the usual oil change superfluous.

As the central element of every disc mower, the cutterbar is a particular focus at KRONE: Welded all round and lubricated for life, it is manufactured using the latest welding robot and CNC technology – for maximum precision, maximum durability and the highest quality standards.

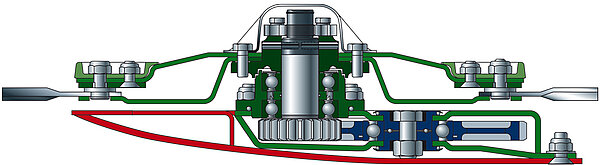

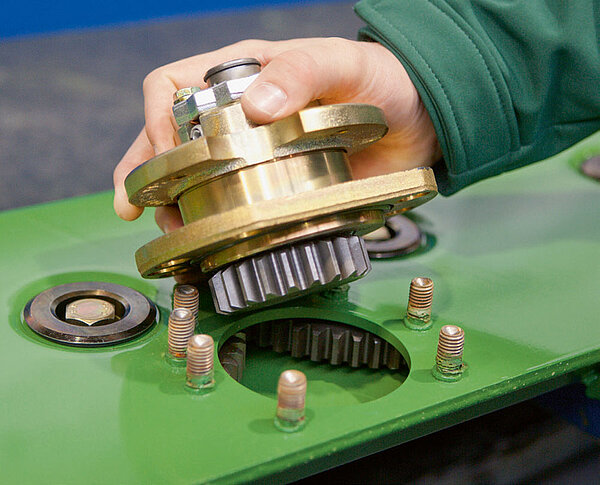

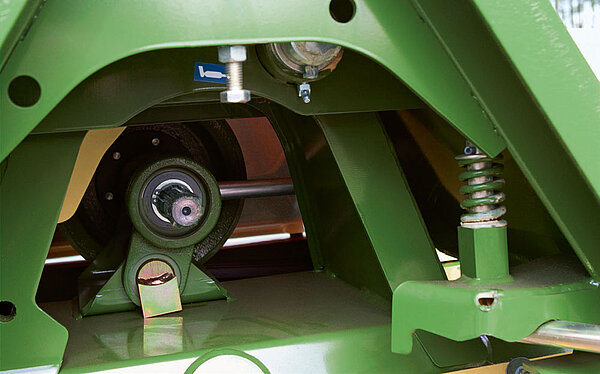

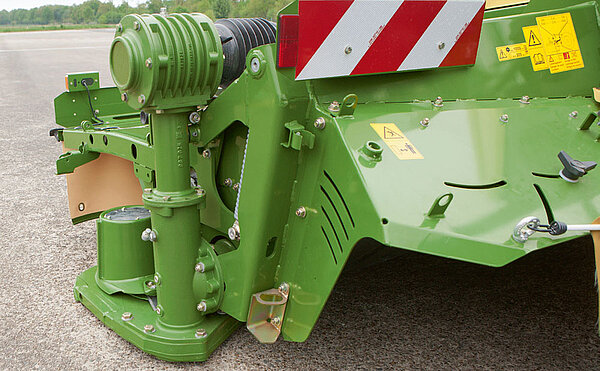

The established satellite drives were developed by KRONE and have proven extremely well all over the world for as many as 30 years now. Its massive spur gears with up to 59 teeth transmit the drive power down to the very last disc. The large-diameter gears rotate at reduced speeds, with a higher number of teeth meshing with the neighbouring spur wheels for even quieter running, ultimate efficiency and maximum longevity. The auxiliary gears drive one cutting disc each and as a result are exposed to only minimum loading.

The cutterbar is driven by the right-angle gearbox just behind the inner mower drum – for blockage-free operation on headlands and in awkward patches.

The wedge-shaped cutterbar offers many height setting options. The spur gears run in massive double bearings, allowing the cutterbar to handle extremely high loads.

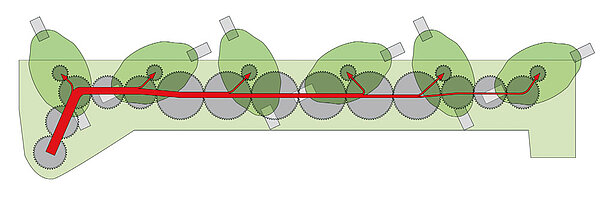

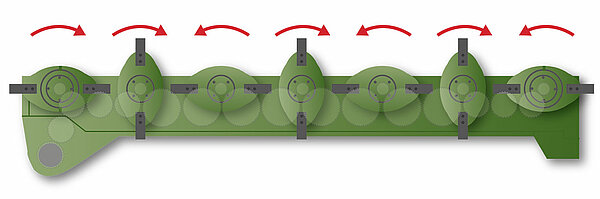

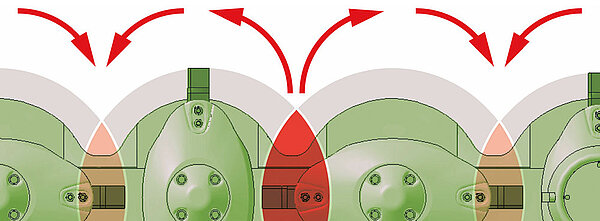

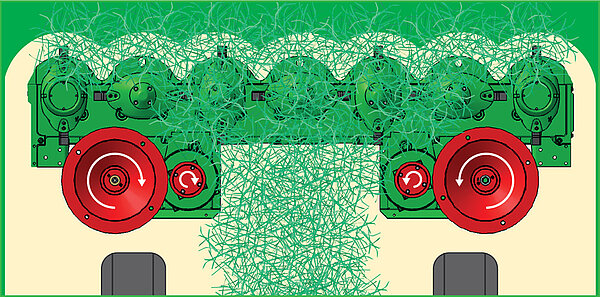

With discs spinning in the B direction of rotation, EasyCut spreads the crops across the full cutting width. All discs alternately turn in pairs, spreading the material across the working width for faster and more uniform wilting.

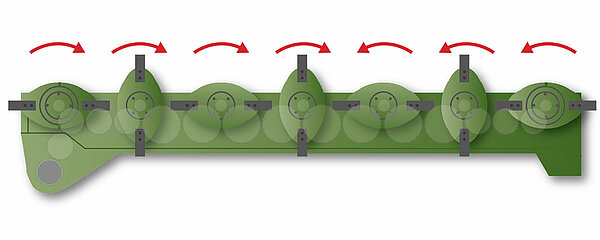

Spinning inwards, the discs feed the material to the middle of the machine to avoid tractor wheels running over the cut crops. With discs spinning in the A direction of rotation, EasyCut F 280 and F 320 form one swath.

The spur wheels are arranged in a forward position and eccentrically inside the bearing housing right under the discs. The small auxiliary spur wheels, including their bearings, are removed from above, the massive ones of the main drive from the side.

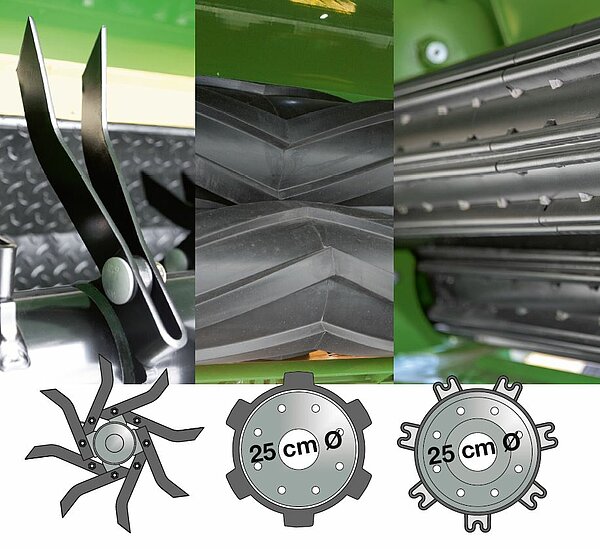

With some discs turning in pairs towards each other and others turning away from each other, it was necessary to redesign the degree of blade overlap to ensure cleanest cuts. For stripeless cuts in light and young crops, we have therefore increased blade overlaps on the discs turning outwards (SmartCut). In addition, the blades turning to the rear are set further apart to encourage a smooth flow of large volumes of crop.

Worn blade fixing pins and wear parts are not an issue for KRONE Easy-Cut, because the modular design of the discs allows you to replace them individually. If you like, you can opt for bolts instead of pins.

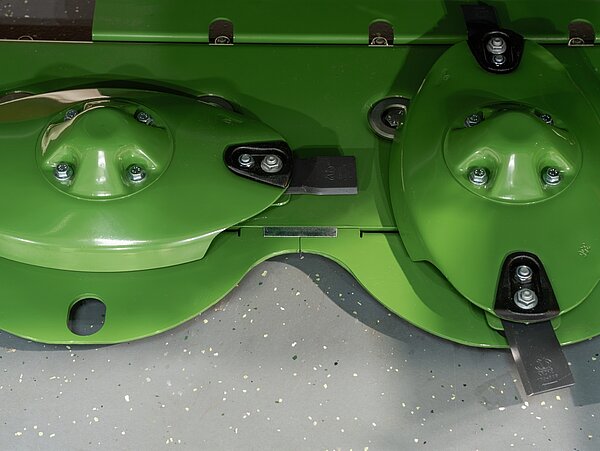

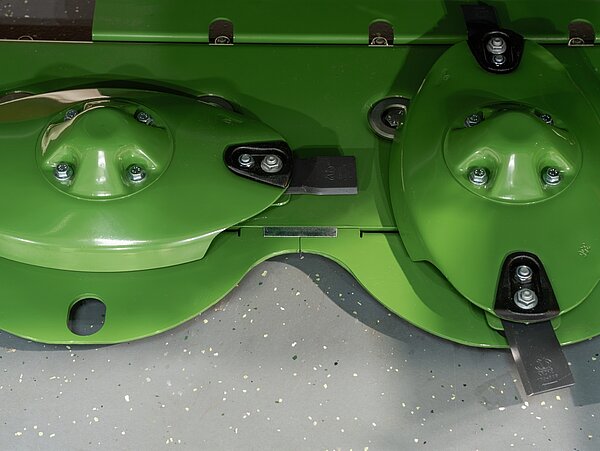

Blades of 112 mm length orbit with a generous overlap, producing the typically clean cuts and feeding the material to the rear in a consistent flow.

The blades are free to spin 360-deg. on their pins. They are hard-wearing and self-cleaning, well protected and will not foul with the blades on the neighbouring discs.

The new optimised cutting discs of the EasyCut B and F models impress with innovative details: A reinforced contour ensures even more stability and resilience. Thanks to the new laser head seam and edge coating, the cutting discs are optimally protected against wear, significantly increasing their service life.

The new sliding skid with full supporting surface improves sward protection and reduces wear. The result: Improved contour guidance, longer service life with a precise cutting pattern – even under the most demanding conditions.

Quick-change blades are a must for many farmers and contractors. These blades are quick and easy to reverse or replace in situ.

If the system is suddenly overloaded, the impact is not directed to the spur wheels of the cutterbar, instead a roll pin in the sprocket drive shaft shears off. The pinion shaft continues spinning, jacking up the cutting disc in question, moving it out of the danger zone and the orbit of the neighbouring discs. As a result, SafeCut prevents damage to the spur gears and the neighbouring discs. The roll pins can be replaced in just a few minutes and cost next to nothing.

Each cutting disc on the cutterbar has its own individual impact protection. When the blade hits an obstacle the shockload is transferred to a roll pin which breaks. As a result, the cutting disc automatically threads 15 mm up on the drive shaft.

There is no load on the roll pins during operation. The bearing is tensioned by a nut and two clamping screws. As a result, the roll pins do not suffer from material fatigue and even after many hours of operation they will break only at their inbuilt load level.

Orbiting within the sphere of the mower bed and never protruding beyond the skids, the EasyCut discs benefit from two-fold protection. Additional protection comes from the standard SafeCut system.

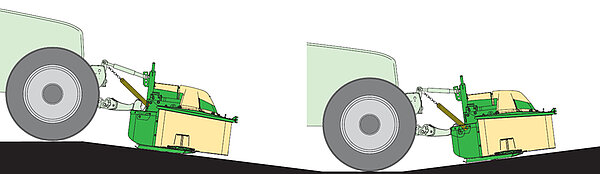

Oblong holes for the two lower link pins allow the mower to pivot laterally and follow every contour even in the most difficult terrain, providing best protection to the mower and the sward.

The flexible and telescopic top link (option) allows the cutterbar to follow any contour and produce a perfect cut.

Particularly stable, adjustable relief springs ensure optimum bearing pressure of the mower for best contouring and sward protection.

Although offering a 3.16 m cutting width, the EasyCut F 320 M and F 320 fold into a very compact transport unit. The ends of the side guard fold back to bring the transport width down to 3.00 m. A hydraulic fold mechanism is an option.

The sloping deck and the stretched guard cloths prevent ingress of debris and the mower stays clean.

The PUSH headstock on the push-type EasyCut F320/360 M and F 320 front mounted mowers is compact by design and offers a reduced weight and length reducing the weight on the front hydraulics.

The EasyCut F 320 PUSH and PULL models have two massive and powered swath drums that produce a uniform swath for the tractor to straddle it. By comparison, the F 320 M / F 360 M PUSH and PULL spread the material across the full work width for more uniform wilting and reduced machine weight.

The front guard opens up wide for convenient servicing and blade replacement. An integral drawer stores the spare blades right on the machine.

The sloping deck collects less material and the spring-tensioned dirt cloth stays cleaner. Canvas curtains won’t rust, save weight, protect the cutterbar and enhance the mower’s ability to follow the ground contours.

The current ground pressure is shown on the pressure gauge and can be altered hydraulically from the tractor seat for on-the-move adjustment to varying conditions. A lockable tap allows operators to carry out up/down and lock/release functions.

The mower is suspended in its centre of gravity, a design that increases the machine’s up/down travel by up to 18° and guarantees the sward is not damaged in undulating terrain. When hitting an object, the mower breaks back and to the rear without altering its cutting height.

The pulled EasyCut F 320/360 M and F 320 front mounted mowers attach quickly and easily and without A-frame to the tractor linkage. A single-acting hydraulic cylinder that is integrated in the headstock and lifts the mower clear of the ground for smooth headstock turns.

The large supporting surface gives best contouring and height control even in difficult terrain. The low bearing pressure makes floating even easier to avoid any scuffing.

The flexible and telescopic top link (option) allows the cutterbar to follow any contour and maintain a uniform cutting height.

The EasyCut F 280 and F 320 follow any ground contour axially and transversely. Their push-type configuration gives them an immense pivoting range and plenty of clear space all round, which is ideal in extremely undulating terrain. Compact by design and offering an excellent visibility, they offer great operator comfort in the field and in road transport. Mounted close to the tractor, they minimise vertical travel of the lower link and reduce wear on the universal shaft.

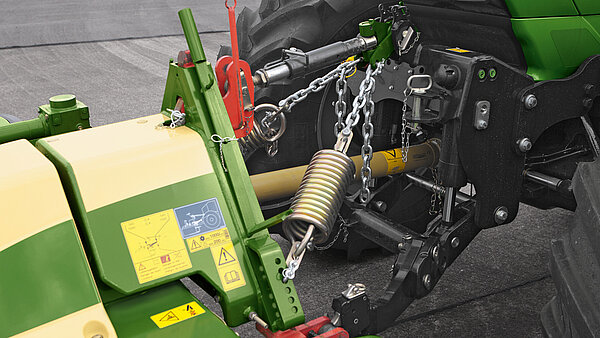

The bearing pressure is controlled via the perforated bars by refitting the chains and the pins that hold the tension springs in place. After all, an optimum bearing pressure is fundamental for consistent cuts and high acreage output. Chains on the inside of the springs protect these from overexpanding.

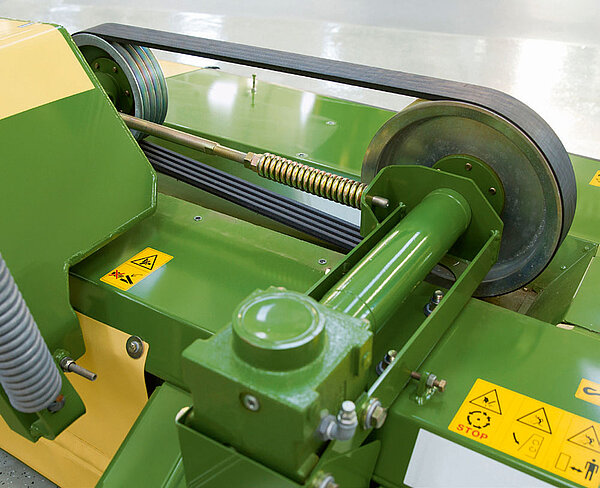

The drive power flows down a kraftband that is tensioned automatically and enters the cutterbar through a right-angle gearbox and the swath drum. The freewheel is integrated in the universal shaft as a standard.

All cutting discs on EasyCut F 280 and F 320 spin inwards, feeding the material to the middle and forming the swath. The powered swath drums feed the crop flow to the rear for a perfect swath - even on slopes.

Lights and warning panels are an option on EasyCut F 280 and F 320. The two front mowers are supplied with standardized brackets that are suitable third-party lights as well.

Cutting at a uniform ground pressure across the full work width, the EasyCut F 280 and EasyCut F 320 mowers suffer less wear, operate smoothly and leave perfect cuts.

The front and side curtains have rubber bumper strips that protect them from damage and retain the value of the mower.

Integral coil springs suspend the mower horizontally when lifted out of work. The hydraulic damper absorbs lateral vibrations and enhances operator comfort.

Pivoting through a large 40 cm range, these disc mowers follow any ground contour, produce clean forage and leave a healthy sward.

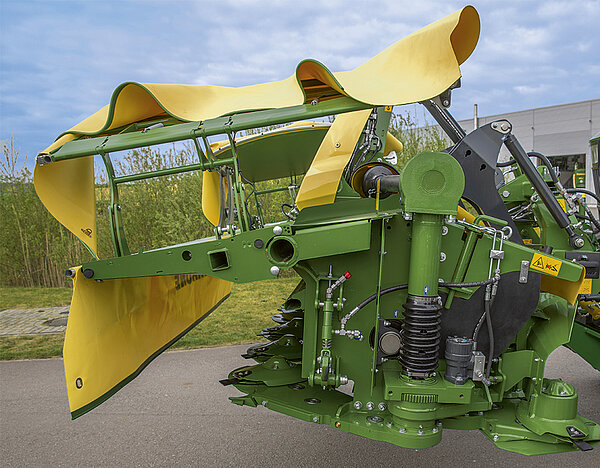

A large merger auger is available ex works for all EasyCut F 320 and F 360 Gen. 4. With a diameter of 450 mm, the merger auger reliably and evenly conveys even large quantities of forage between the tractor wheels – without running over the forage. The swath width can be flexibly adjusted using adjustable swath flap extensions – ideal for different types of tractor or downstream harvesters.

Exclusively available for the EasyCut F 320 Gen. 4, the Plus headstock has been specially developed for use on slopes. The integrated A-frame enables large swing paths and ensures optimum ground tracking on slopes. A pendulum stop cylinder (single-acting) increases stability on the headland. At the same time, the Plus headstock is particularly easy to attach and detach – for greater convenience in daily use.

Easy adaptation to different tractors makes the Pull headstock particularly versatile. Hydraulic relief is integrated as standard and can be conveniently adjusted from the cabin. A single-acting control unit is all that is needed to regulate the bearing pressure or to fold the mower in and out. Generous swing paths in all directions ensure a clean cut even on uneven terrain.

With its lightweight design and close connection to the tractor, the Push headstock offers a particularly compact unit. The telescopic top link ensures optimum ground tracking – both in line with and at right angles to the direction of travel. The bearing pressure can be adjusted easily and without tools using springs – for the best cutting quality.

Thanks to their sophisticated design, the mowers can be individually configured. The optional merger auger can be integrated at the factory or retrofitted if required. KRONE offers complete adaptation freedom, even for the headstock: Push, Pull and Plus variants are available and can be easily exchanged as required – for maximum versatility throughout its service life.

For even greater convenience when moving the machine, the side guards can be folded hydraulically as an option (1×double-acting). This enables a narrow transport width of less than 3.00 metres to be implemented quickly and conveniently – directly from the tractor seat.

An optional lighting system is available for transport on public roads. It increases visibility in road traffic and provides additional safety at dusk or in poor visibility conditions.

The front guard can be easily opened for maintenance and for changing blades. This means that the cutterbar is quickly and safely accessible – for maximum user-friendliness with minimum effort.

The EasyCut F 320 and F 360 Gen. 4 impress with a completely revised design. Tightly tensioned guard cloths ensure clean lines, reduce dirt deposits and increase durability.

This lever in the multi-step gate varies the gap between the tines and the baffle plate. As you reduce the gap you increase the intensity of conditioning.

The CV conditioner has ‘two-in-one’ pulleys that offer two speeds. Using the quick-change blade tool, you can easily slacken and replace the belt.

The machine offers both. Set the swathing width by adjusting the swath flap extensions. Optional deflector sheets ensure a consistent and uniform distribution of the crop across the full work width.

The v-shaped tines are made from hardened steel and mount at a steep angle, treating the forage intensively and powerfully. The tines pivot to the rear when hitting a foreign object whereas forward pivoting is restricted to increase the service life of the bolts.

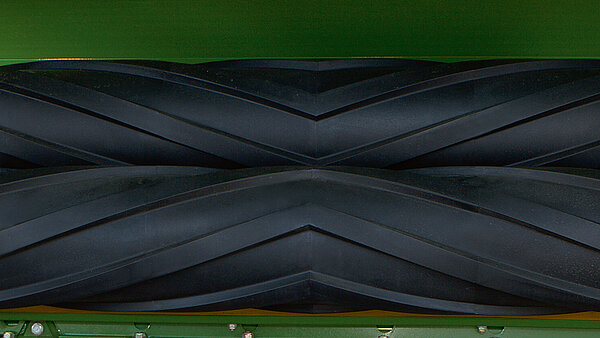

The counter-rotating M-Rolls mesh to crush the material and yet leave a sufficiently wide gap for the material to pass through. The result is a uniform conditioning quality for uniform wilting and no rolling losses – the perfect system for lucerne, for example.

The top roller of the M-Rolls is driven by a separate gearbox on the right end of the cutterbar which synchronizes the speed of the top and bottom rollers, bracing you for wet and heavy crops.

The large-diameter CR conditioner rotors deliver a smooth and consistent flow of crop and have a low power input.

The full-width polyurethane rollers ensure a uniform conditioning effect across the entire work width and the polyurethane coating ensures maximum longevity. The interlocking surfaces of the rollers give intensive but gentle conditioning whilst avoiding losses.

The conditioning rollers are driven by gearboxes. The box that drives the bottom roller is integrated in the gearbox that powers the cutterbar. The top roller suspends from a spring which ensures a continuous flow in inconsistent growth and allows foreign objects to pass the system trouble-free. Thanks to a stepless adjustment system, the operator adapts the gap and pressure steplessly to current yields.

Each end of the guard can be folded back to bring transport width down to 3 m. This can also be done hydraulically from the tractor as an option.

The pulled headstock has a hydraulic cylinder that raises the mower extra high, providing plenty of ground clearance in any type of terrain. This means there is plenty of clearance for butterfly combinations to handle high-volume swaths on the headland.

The pulled headstock design allows the machine to break back and up through a larger angle, hence making it more suitable for operation in rolling land.

A CCTV camera system is an option for all models that are coupled without A-frame. The system is DLG certified and offers two views on the same screen for improved visibility in awkward situations. For example, narrow field gates are now easily managed without a helper. The package comprises two cameras, the display screen and the necessary wiring.

With no A-frame required, there is plenty of space around the headstock. The pushed design makes for a very compact machine, reduces weight and is gentler on the turf. The transverse pivoting action is provided by the tractor’s link arms. The pulled version has the suspension springs integrated in the machine’s suspension system. The tension of the two springs is controlled from one single crank.

Powerful tractors and massive equipment call for strong and sturdy coupling hardware. This heavy-duty three-point headstock withstands high machine weights and strains and offers fast and easy attachment/removal.

Adjustable relief springs optimise the bearing pressure and allow the cutterbar to float. A telescopic top link (option) is available to deliver perfect cuts in undulating terrain.

The floating EasyCut F 360 CV and F 360 CR in pushed configuration are compact and slim machines that provide excellent visibility. These machines impress by a low dead weight and cleanest cuts.

The pulled model has an integral hydraulic cylinder that provides plenty of ground clearance when the machine is being lifted out on the headland or when working in rough terrain. You can increase the lift by raising the tractor lower link to master even the most difficult situations.

The pull-type configuration gives the mower more than 30 cm transverse travel for cleanest cuts also in undulating fields.

The KRONE EasyCut F 360 CV and CR front mowers can have a pull-type suspension. This allows the mower to break back and up for added protection from foreign objects.

Centrally adjustable relief springs via a spindle optimise the bearing pressure and make for perfect cuts. The suspension springs are integrated in the linkage, a design that eliminates the need for attaching and removing them when attaching/removing the machine.

The hydraulic mower suspension and the new headstock provide more than 1 m up/down travel and perfect contouring.

The EasyCut F 400 Fold shows its strengths especially in combination with KRONE butterfly mowers: Strip-free mowing on difficult field layouts and slopes.

Maximum operator comfort: The EasyCut F 400 CV Fold has hydraulic end guards as standard so operators can fold them up/down from the seat. Folding the guards or the cutterbars into position requires only one double acting spool.

The EasyCut F 400 CV Fold and the EasyCut F 400 Fold have hydraulic side guards as standard. From the convenience of his seat, the operator controls the position of the cutterbars and the sequential position of the side guards via a double-acting control unit.

To prepare the machine for road travel, the two mower drums on either side swing behind the tractor wheels. The hydraulic slewing gear is controlled automatically from the tractor cabin. Transport width: under three metres.

Coupling directly to the lower links of the tractor, the new KRONE headstock does without an A-frame. The hydraulic relief is integrated in the lifting mechanism so that only one single-acting and one double-acting control unit are required. The side guard cloths and the foldable mower drums are sequence controlled from the convenience of the cabin.

The EasyCut F 400 CR mower offers a generous working width of 4 metres. To make best use of the full width, it can be combined with the EasyCut B 1000 CR, for example, to achieve an overcut of 57 cm per side. This ensures strip-free mowing under all conditions. With a transport width of only 3 metres, the mower is extremely agile, making it easier to manoeuvre on narrow roads and in the farm yard.

The hydraulically foldable side guards available as an option can be conveniently controlled from the cabin.

The KRONE front mounted mower EasyCut F 400 CR is equipped with a rigid cutterbar and CR conditioner rollers as a standard. The intermeshing of the rollers gives intensive but gentle conditioning whilst avoiding losses. The EasyCut F 400 CR is particularly well suited large-scale cultivation of lucerne, to be found for example in the USA or Australia. For optimum conditioning of the crops under all conditions, the EasyCut F 400 CR can be equipped either with CR- or M-Roll conditioner rollers.

Dairy farmers are looking into the potential of fresh grass for increasing milk yields from the basic ration. In view of rising silage storage costs, hay milk production programmes and further aspects fresh mass is being viewed from a different angle today. This new approach is supported by KRONE who offers the ideal machines that help you cut and feed highly valuable fodder every day. Combining the EasyCut F 400 CV Fold mower with the MX 330 GD forage wagon makes a powerful punch.

The foldable cutterbar of the KRONE EasyCut F 400 Fold makes working in cramped locations with bad visibility easier. Its transport width of less than 3 m ensures perfect handling, particularly when depositing the forage on narrow tables.

Immediately after depositing, the loading and forage transport wagon picks up the swaths cleanly and evenly before placing them loss-free on the forage table via the cross conveyor belt available ex works.

The merger auger deposits the crops in a compact, evenly shaped swath. This not only provided for quick, efficient harvesting but also ensures improved forage quality.

The perfect combination of KRONE machines: The EasyCut F 400 Fold front mounted mower with merger auger and the loading and forage transport wagon RX with 40 m3 loading volume constitute the KRONE Fresh Matter-Express, which stands for maximum efficiency and unsurpassed forage quality.

The combination goes into narrow buildings and feed passages thanks to the patented slewing gearbox which allows the wide mower to be folded into a narrow unit.

The feeding unit discharges the feed on to small and large any feed passages in no time. Mounted cleverly at the tailgate, the discharge belt enables owners to use the MX for feeding fresh grass directly to the cows.

The position sensor can detect the working position (active) and transport position (inactive) by the alignment of the SmartConnect Solar. With a stored working width, the SmartConnect Solar can also be used as a hectare counter. Alternatively, it is possible to record the loads on transport vehicles by opening/closing the tailgate.

As the KRONE SmartConnect Solar has an autonomous power supply and can be mounted regardless of the manufacturer, it is ideal for use on rental machines. In this way, you always know where your rented machine is. The precisely documented working hours and acreage output enable transparent and accurate invoicing of the rental machines.

With this autonomous telemetry unit, even simple machines such as mowers, tedders, rakes and other implements without their own electronics can be integrated into a digital data management system.

The right model for every field of use

| EasyCut F 280 | EasyCut F 280 M | EasyCut F 320 (2. Gen) | EasyCut F 320 (3. Gen) | EasyCut F 320 M (2. Gen) | EasyCut F 320 M (3. Gen) | EasyCut F 320 CV | EasyCut F 320 CR | EasyCut F 360 M | EasyCut F 360 M | EasyCut F 360 CV | EasyCut F 360 CR | EasyCut F 400 CV Fold | EasyCut F 320 (Gen. 4) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Work width (m) | 2.71 | 2.73 | 3.14 | 3.14 | 3.16 | 3.16 | 3.16 | 3.16 | 3.60 | 3.60 | 3.60 | 3.60 | 4.04 | 3.16 |

configure

|

| PUSH design | series | series | series | series | series | series | series | series | series | series | series | series | - | series |

configure

|

| PULL design | - | - | - | optional | - | optional | optional | optional | - | optional | optional | optional | series | optional |

configure

|

| No. of discs | 4 | 4 / 2 optional | 5 | 5 | 5 / 2 optional | 5 | 5 | 5 | 6 / 4 optional | 6 | 6 | 6 | 5 | 5 |

configure

|

| No. of top hats | 2 | 2 / 4 optional | 2 | 2 | 2 / 4 optional | 2 | 2 | 2 | 2 / 4 optional | 2 | 2 | 2 | 4 | 2 |

configure

|

| Conditioner | - | - | - | - | - | - | series | - | - | - | series | - | series | - |

configure

|

| CR conditioner with rubber rollers | - | - | - | - | - | - | - | series | - | - | - | series | - | - |

configure

|

| Power requirement kW/hp | 44 / 60 | 40 / 55 | 51 / 70 | 51 / 70 | 48 / 65 | 51 / 70 | 59 / 80 | 59 / 80 | 54 / 75 | 51 / 70 | 66 / 90 | 90 / 90 | 74 / 100 | 51 / 70 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)

![[Translate to EN:]](/fileadmin/_processed_/1/9/csm_A001C1039_240428_PF13_250528_f834add98a.jpg)

![[Translate to EN:]](/fileadmin/_processed_/6/8/csm_DJI_20250430115716_0196_D_AK_277123_add5cf2d5b.jpg)

![[Translate to EN:]](/fileadmin/_processed_/0/9/csm_DJI_20250430125450_0203_D_AK_277372_128a6c5275.jpg)