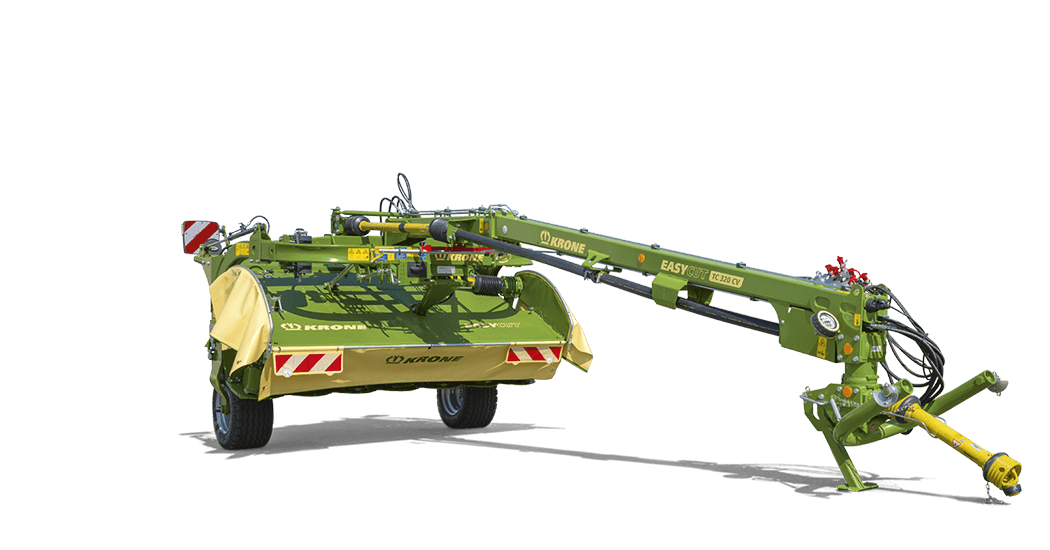

The EasyCut trailed mowers with a working width of 2.71 m to 3.60 m offer maximum flexibility and, thanks to their wide variety, meet the most diverse requirements worldwide. The TS models score on their compact design and the TC models on versatility. The central drawbar gives you the option of working to the right or left of the tractor. These trailed mowers are available either with tine conditioner or roller conditioner. All conditioner models can be equipped with the KRONE Collect system.

- Mowers with side-mounted (TS) and mid-mounted drawbar (TC)

- Robust and fully welded cutterbar with massive and permanently lubricated sprockets

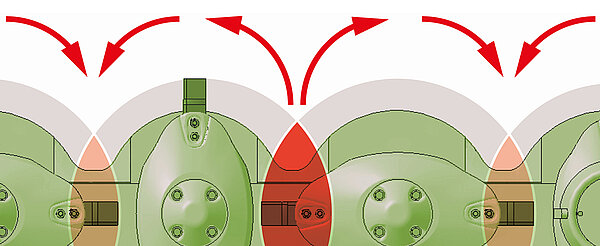

- SmartCut: Stripe-free swath with especially wide overlap of the blade tracks

- SafeCut: Individually protected cutting discs

- Quick-change blades are standard specification

- DuoGrip: Centre of gravity mounting with double guidance for best ground adaptation

- Tine conditioner (CV) or roller conditioner (CR) for fast and uniform wilts

- Optional Collect cross belt increases your swathing options

Product video

KRONE EasyCut TC/TS trailed disc mowers

The trailed mowers offer the highest degree of flexibility and meet the most diverse requirements worldwide. The TS models impress by their compact design, the TC models by their wide range of applications. With the central drawbar you have the possibility to work at the right or the left side of the tractor. These trailed mowers are available with either V-steel tine or roller conditioner. All conditioner models can be equipped with the KRONE Collect system.

Animation

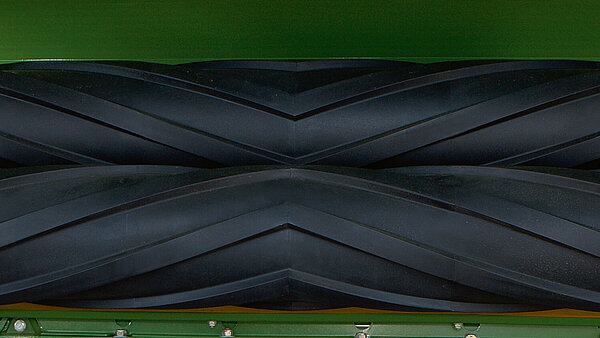

KRONE M-Rolls conditioner

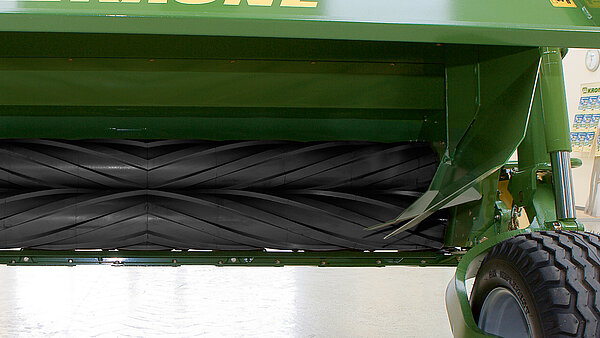

The new trailed machines are available with the well-proven V-steel tines (CV) or the CR roller either with rubber rollers or the new M-Rolls. These feature an M-profile tread that suits especially demanding conditions such as leafy crops or stone-strewn fields. The 25cm diameter M-Rolls ensure an effective crop flow even in high-yielding crops. They kink the haulms multiple times, reducing the drying time in the field and ensuring a uniform wilting process and an exemplary quality of forage.

Product features

These new trailed mowers from KRONE have a mid-mounted drawbar that offers maximum flexibility when operating the machine solo or in combination with a front mower. The new trailed machines with mid-mounted drawbar offer hydraulic side-shifting, cutting offset to left or right behind the tractor.

Running offside behind the tractor, the new trailed mowers with side-mounted drawbar stand out for a straightforward and compact design. The short, sidemounted drawbar is perfect for managing turns on tight headland. The mower teams up with a front mower to boost productivity.

The counter-rotating M-Rolls crush the material for more uniform conditioning and wilting.

The full-width and chevron-profiled rollers mesh to achieve the best results in leguminosae and other leafy crops.

The pivoting V-shaped tines provide uniform conditioning across the full work width.

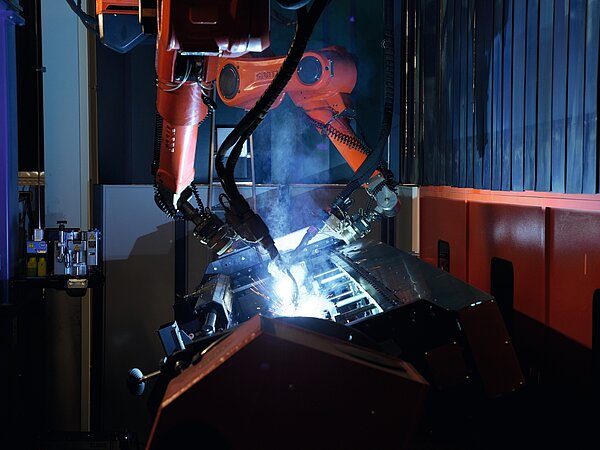

The all-round welded, enclosed cutterbar is maintenance-free and remains reliably sealed and dimensionally stable even after many years of use. Special cleaning processes during production enable lubrication for life and make the usual oil change superfluous.

As the central element of every disc mower, the cutterbar is a particular focus at KRONE: Welded all round and lubricated for life, it is manufactured using the latest welding robot and CNC technology – for maximum precision, maximum durability and the highest quality standards.

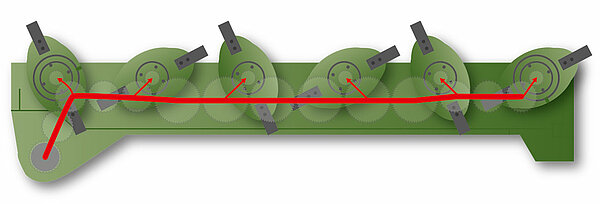

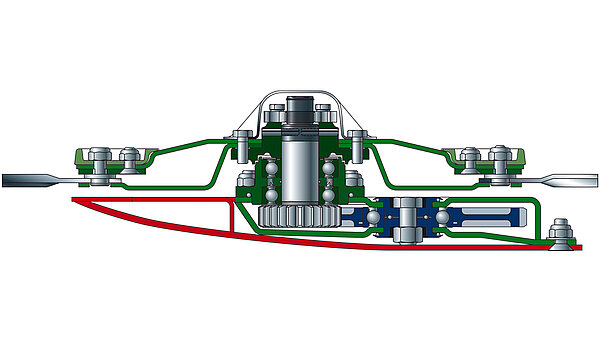

The KRONE developed satellite driveline comprises massive spur gears with up to 66 teeth which transfer the power all the way down to the very last disc. The large-diameter gears rotate at reduced speeds, with a higher number of teeth meshing with the neighbouring gearwheels for even quieter running, ultimate efficiency and maximum longevity. The auxiliary gears drive one disc each and as a result are exposed to only minimum loading,

The cutterbar is driven by the right-angle gearbox just behind the inner top hat – for blockage-free operation on headlands and in awkward patches.

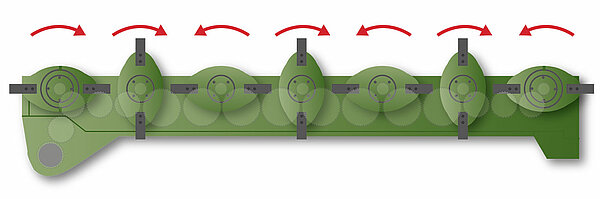

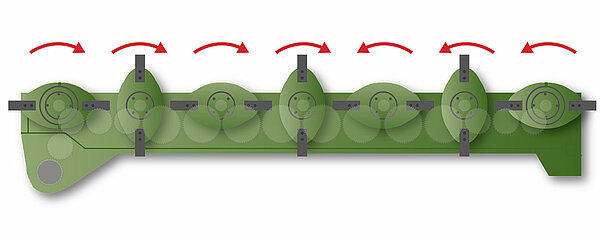

With discs spinning in the B sense of rotation, EasyCut spreads the material across the full cutting width. All discs turn in pairs, spreading the material across the working width for faster and more uniform wilting.

To prevent the mown forage from being run over by the tractor wheels, the bearing housings are positioned so that the discs rotate towards the centre.

The spur gears are arranged in a forward position and eccentrically inside the gearbox right under the discs. The small auxiliary spur gears are removed from above, the massive main gears gearbox from the side.

With some discs turning in pairs towards each other and others turning away from each other, it was necessary to redesign the degree of blade overlap to ensure cleanest cuts. For stripeless cuts in light and young crops, the blade overlaps on the dises turning out- wards have increased substantially. In addition, the blades turning to the rear are set further apart to encourage a smooth flow of large volumes of crop.

The wedge-shaped cutterbar offers many height setting options. The spur gears run in massive double bearings, allowing the cutterbar to handle extremely high loads.

Worn blade fixing pins and wear parts are not an issue for KRONE EasyCut, because the modular design of the discs allows you to replace them individually. If you like, you can opt for bolts instead of pins.

Blades of 112 mm length orbit with a generous overlap, producing the typically clean cuts and feeding the material to the rear in a consistent flow.

The blades are free to spin 360-deg on their pins. They are hard-wearing and self-cleaning, well protected and will not foul with the blades on the neighbouring discs.

We welded curved stops between the individual skids that protect the cutterbar from damage and also contoured the underside of the stops in such a way that no material can build up here and instead flows smoothly to the rear.

High-cutting skids are the solution for those who want 80 mm and longer stubble. Depending on how you bolt the skids to the cutterbar, you can increase the cutting height by 30 mm or 50 mm, which is ideal in forage and whole crop silage.

Made from hardened steel, the extra wide skids reduce the ground pressure and hence offer effective protection of both the cutterbar and the sward. The skids are bolted to the cutterbar so they are easy to replace.

Quick-change blades are considered a must by many farmers and contractors. The blades are quick and easy to reverse or replace in situ.

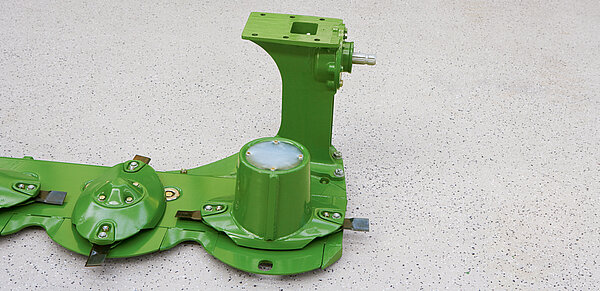

If the system is suddenly overloaded, the impact is not directed to the spur gears in the driveline, instead a roll pin in the sprocket drive shaft shears off. The pinion shaft continues spinning, jacking up the disc in question, moving it out of the risk zone and the orbit of the neighbouring discs. As a result, SafeCut prevents dam- age to the spur gears and the neighbouring discs. The roll pins can be replaced in just a few minutes and cost next to nothing.

Each disc on the mower has its own individual impact protection. When the blade hits an obstacle the shockload is transferred to a roll pin which breaks. As a result, the disc automatically threads 15 mm up on the drive shaft.

There is no load on the roll pins during operation. The bearing is tensioned by a nut and two clamping screws. As a result, the roll pins do not suffer from material fatigue and will break only at their inbuilt load level - even after many hours of use.

Orbiting within the sphere of the mower bed and never protruding beyond the skids, the EasyCut discs benefit from two-fold protection. Additional protection comes from the standard SafeCut system,

The curved frame results in a greater lift-out height during headland turns and increases the lateral travel for enhanced performance in extremely undulating terrain. The drawbar is mounted in the middle of the machine and above the axle for enhanced stability in sloping fields.

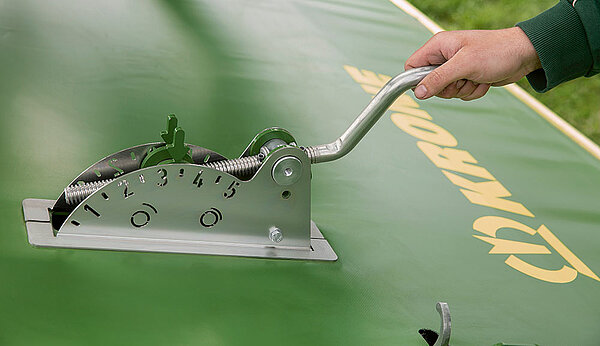

The cutting height is controlled by operating this crank handle. The current height is indicated on the scale. Hydraulic height control is an option. The grey box stores spare blades for quick blade changes and is a standard feature on all EasyCut models.

DuoGrip allows the EasyCut mowers to deliver particularly clean and tidy cuts whilst protecting the sward. Suspended in their centre of gravity and pulled by a short arm, the mower operates at a consistent ground pressure across the entire work width which is set hydraulically from the convenience of the cab. The operator views the ideal ground pressure on the gauge. Two parallel steering rods give additional guidance by absorbing any side draft, improving the guidance, and increasing the overall stability. The modular design of the new curtains reduces machine weight and prevents material from collecting on the machine.

Running inline behind the tractor during road travel, EasyCut TS 320 does not exceed the statutory 3 m transport width, gives plenty of ground clearance and is approved to 40 km/h maximum speed. This is the machine to travel quickly between sites.

The front curtain folds up to give convenient access to the discs for easy cleaning and blade replacement.

Equipped with side-mounted drawbar and pivoting gearbox, the unit cuts around any bend. The two-point headstock attaches to the height-adjustable link arms – although the floating drawbar has become the preferred choice of attachment in some countries.

It takes just a minute to adjust the machine perfectly to the current conditions. The cutterbar's ground pressure is set by tensioning the coil springs.

The V-shaped frame of the EasyCut TS 320 model with sidemounted drawbar is robust and compact. Its generous ground clearance makes for plenty of vertical travel. Suspended in its centre of gravity and linkage controlled, the cutterbar swings back and up through a large angle avoiding obstacles, a design that ensures clean work also in undulating fields. The cutterbar is driven by a powerful right-angle gearbox which makes for a frictional connection and is arranged behind the inner top hat.

The trailed EasyCut TS 320 without conditioner impresses by its superior performance, very light draft and good ride qualities. Compared with a mounted mower, the trailed machine reduces the load on the tractor's rear axle and its hydraulics. As another plus, it offers a much lower transport height and hence better road safety. The transport position does not exceed 3.00 m.

Select 900 rpm for intensive treatment and 600 rpm for less intensive conditioning. Setting the speed is easy from the gearshift lever.

The standard baffl e plate on the CV conditioner adds to the conditioning eff ect of the tines for more intensive conditioning.

The distance between the tines and the chequer sheet can be easily adjusted using the crank handle. As you reduce the gap you increase the intensity of conditioning.

The tine conditioners on each mower span across the work width from the left to the right top hat, providing a uniform and consistent crop flow across the full width and giving optimum conditioning.

The v-tines are made from hardened steel and mount at a steep angle, treating the forage intensively and powerfully. The tines pivot to the rear when hitting a foreign object The limited pendulum travel towards the front increases the lifetime of the bolts.

The top roller suspends from a spring which ensures a continuous flow in inconsistent growth and allows foreign objects to pass the system trouble-free. The roller distance and contact pressure can be adjusted to suit different forage quantities and types. The roller conditioner is driven by a gearbox.

The counter-rotating M-Rolls mesh to crush the material and yet leave a sufficiently wide gap for the material to pass through. The result; uniform, intensive conditioning for homogeneous drying processes without rolling losses; ideal e.g. for recov- ering lucerne.

The top roll of the M-Rolls is driven by a separate gearbox on the right end of the cutterbar which synchronizes the speed of the top and bottom rolls, bracing you for wet and heavy crops.

The large-diameter CR conditioner rotors deliver a smooth and consistent flow of crop and have a low power input.

The full-width polyurethane rubber rollers ensure a uniform conditioning effect across the entire work width and the polyurethane rubber coating ensures maximum longevity. The interlocking surfaces of the rollers give intensive but gentle conditioning whilst avoiding losses.

The trailed EasyCut disc mower conditioners with cross belts suit a wide range of applications. Being true all-round machines, they operate with and without the belts. When the belts are out of work, the mower produces either wide or compact single swaths. With the belts in work, they feed the material on or next to the existing swath, forming a double swath that suits the full pick-up capacity of the following harvester.

The conditioner tines on a machine that has the swathing belt also serve to feed the material to the belt. To increase the efficiency of the throw, the spaces between some tines are covered

The 91 cm wide cross belt with bolted bars feeds the crop consistently to the side, producing particularly uniform swaths that are very easy to pick up by the following harvester. An on-board hydraulic system comprising an oil reservoir, a pump and a hydro motor powers the belt and eliminates any hydraulic input from the tractor. The belt stops and restarts automatically when the mower lifts and lowers out of and back into work. Varying the belt speed infinitely variably varies the width of the swath.

All TS/TC models offer cutting height control from the cab as an option. But also the Tilt feature helps dealing with obstacles. The cutting height is raised temporarily to avoid machine damage and yet avoid raising the machine.

Depending on the position of the drawbar, this double arrow indicates the current overlap, clearly indicating the current setting depending on the tractor width and the current transport position of the drawbar.

The front curtain folds up to give convenient access to the discs for easy cleaning and blade replacement.

With drive shafts running on the sides and the slewing gearbox being a standard fit, opening fields and turn- ing on headlands becomes a straightforward and easy affair, saving time and boosting efficiency.

The side guards fold up for optimum road safety. Hydraulic folding is an option for more operator comfort. This changes the 3.20 m work width into a less than 3 m road width – what’s wide in the field turns into narrow on the road.

The electric preselection box enables easy and effective operation of the coupling frame and its mowers. A dedicated hydraulic system ensures safe working. One single-acting and three double-acting control units are required to control the mowers individually or synchronously. The overlap towards the front mounted mower can be freely varied depending on the structure of the area.

This combination showed EasyCut TC 500 CR twice in the "Oaten Hay". The entire drive train of the EasCut TC Connect is designed to cope with the steadily increasing tractor output. Over 12 m are mown here in one piece and laid down in swaths.

Combining a KRONE front mounted mower, two trailed centre drawbar models (TC) and the new Easy- Cut TC Connect coupling frame provides maximum efficiency in the field. The tower gearboxes of the TC models allow an attachment transverse to the direction of travel. Attachment points for transport are provided on the EasyCut TC Connect. Even solo operation of only one machine is still possible.

The right model for every field of use

| EasyCut TS 320 | EasyCut TS 320 CV | EasyCut TS 320 CR | EasyCut TC 320 CV | EasyCut TC 320 CR | EasyCut TS 360 CV | EasyCut TS 360 CR | ||

|---|---|---|---|---|---|---|---|---|

| Work width (m) | 3.16 | 3.16 | 3.16 | 3.16 | 3.16 | 3.60 | 3.60 |

configure

|

| Drawbar type | side | side | side | center | center | side | side |

configure

|

| No. of discs | 5 | 5 | 5 | 5 | 5 | 6 | 6 |

configure

|

| No. of top hats | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

configure

|

| conditioner | - | V tines | rolls | V tines | rolls | V tines | rolls |

configure

|

| Power requirement kW/hp | 59 / 80 | 59 / 80 | 59 / 80 | 59 / 80 | 59 / 80 | 66 / 90 | 66 / 90 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)

![[Translate to EN:]](/fileadmin/media/products/Scheibenmaehwerke/Bilder/DJI_0090_132179.jpg)

![[Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyCut_F_320_Push_-_EasyCut_TS_320_MG_0086_146895_47bba08e2b.jpg)