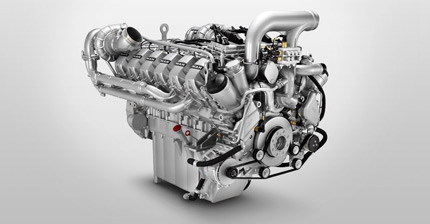

Spelle, 17 August 2010 – Rollout of the new BiG X forage harvester. Today, Krone introduces the latest developments in its successful BiG X range. These stand out for their new common-rail engines from MAN, which deliver higher powers at greater economy and offer operators an absolutely new cab dimension.

The engine features the innovative output management system from Krone, which provides the flexibility of operating to different power curves matched to suit different applications. In road transport, for example, the engine output follows a specific curve that allows the machine to travel at 40km/h at the lowest possible consumption rate.

In the field, the operator selects one of two modes, each mode catering for specific conditions. By comparison, in applications that do not require a high output level (e.g. in second cuts), the operator selects Eco Power mode for extremely economical operation, whereas X-Power mode allows the MAN common-rail system to develop its full power under full load in difficult maize conditions, enabling BiG X to tap into a new – and for a forager – unprecedented dimension of power. Another highlight is the speed control system on the hydraulic-drive cooling fan, which is temperature controlled and brings further economy enhancements.

The new generation of BiG X forage harvester

lines up the following models and

permanent output levels:

BiG X 700: 492 KW / 670 hp

BiG X 850: 607 KW / 825 hp

BiG X 1100: 758 KW / 1031 hp

And of course, our BiG X 500 with its tried and test technology and 6-cylinder inline engine is still available.

The new Krone forage harvesters feature as standard specification the Agritechnica 2009 award-winning VariStream crop flow system. Six pre-compression rollers enhance the pre-compression process and hence the famous Krone quality of chop. Consisting of a spring-loaded base beneath the chopping cylinder and behind the crop accelerator, VariStream ensures blockage-free and smooth operation, even when the flow of crop is not uniform.

The large 660mm diameter and 800mm wide chopping cylinder is a synonym for high throughputs. Users can choose between three different models of chopping cylinders with 20, 28 or 40 knives (Biogas cylinder), all of which are arranged in a chevron formation. The Biogas cylinder will reduce fuel consumption when producing short chops, reducing fuel rates per tonne of harvested crop by up to 16 percent while boosting throughput by up to 25 percent at the same time.

Brand new Silent Space control room

The new engine technology is complemented by an absolutely new cab design and enhanced operator space. Here, operators will enjoy an unprecedented view – courtesy of larger glazing and slimmer posts. High-quality build and enhanced suspension results in lowest noise levels, while the climate control system and a mobile cool box bring an ultimate level of comfort to the workplace. Both features are standard specification on the new BiG X.

The new Krone-developed joystick

is a customized design for self-propelled foragers and combines state-of-the-art ergonomics with comprehensive multi-functionality. A cross control key, for example, offers intuitive and thumb-operated control of all chute functions, as does a second cross control key for all header functions. In addition, the operator no longer has to move his hand to operate regular field functions. Another convenient control is the mode selector button in the armrest, which switches engine modes from X-Power to Eco-Power.

The EasyCollect maize headers

work at 6m to 10.5m widths, and all models have the automatic cutting length control system fitted as standard. This AutoScan system controls the chop length and forage structure relative to crop maturity and with the added benefit of reduced fuel rates. Using the Krone AutoScan system in conjunction with the standard Constant Power engine load limit sensing system will reduce fuel consumption by up to 15 percent. Headers for versatile applications

The Easy Collect header works across rows and at varying row widths. Working to the Collector principle it pulls and feeds the stems lengthways to the chopping cylinder and thereby marks the first step in a chopping system that produces enhanced quality. The Krone EasyCollect headers are available in widths that range from 6m to 10.50m for prodigious work rates whilst achieving an economical fuel rate, even in small fields.

These EasyCollect headers are complemented by two EasyFlow pick-up models that offer work widths of 3m and 3.8m. The Krone EasyFlow pick-up system cuts out the need for a cam track and benefits from a 58 percent reduction in wear parts over traditional pick-up systems, while rotor speed has been boosted by 30 percent. As a result, this innovative technology offers more output at reduced maintenance cost.

The Krone Xdisc direct header works at a width of 6.2m and features large feed augers that boast high throughputs without the risk of wrapping long-haulmed crops.

Last but not least, Krone also markets the WoodCut header for harvesting short rotation crops with up to 150mm diameter trunks. The header will clear up to one hectare of woodland per hour, which translates into wet matter yields of up to 250m3.

Ten years of BiG X

Krone presented the first BiG X forage harvester in May 2000. At that time, the design was spearheading a number of features that are now commonplace in today's forager technology, including 40km/h transport speeds, fully hydrostatic and stepless transmission and 6 pre-compression rollers. With a line-up of models from 500hp to more than 1000hp, the full BiG X range of forage harvesters is yet another Krone statement that marks its position in the forager market.

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)