- KRONE SmartCut: Stripe-free cutting

- KRONE quick-change blades

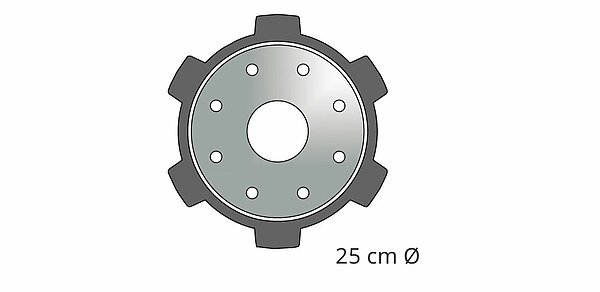

- KRONE SafeCut: Individually protected cutting discs

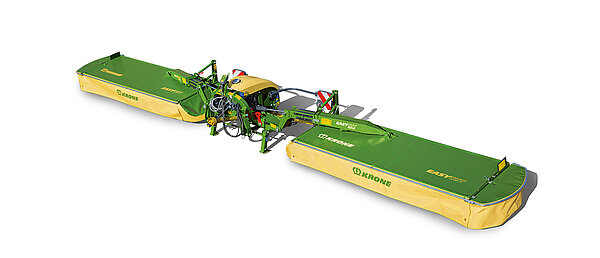

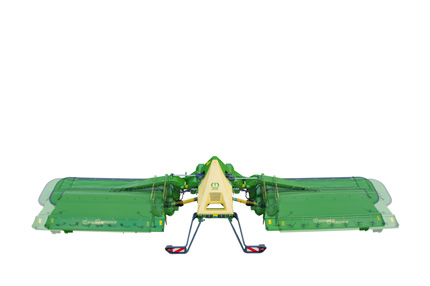

- EasyCut B 870 and B 1000 without conditioner

- EasyCut B 950 Collect without conditioner, with auger conveyors

- EasyCut B 880 and B 1050 CV/CR Collect

- EasyCut B 1050 CV: With BiG Swath System

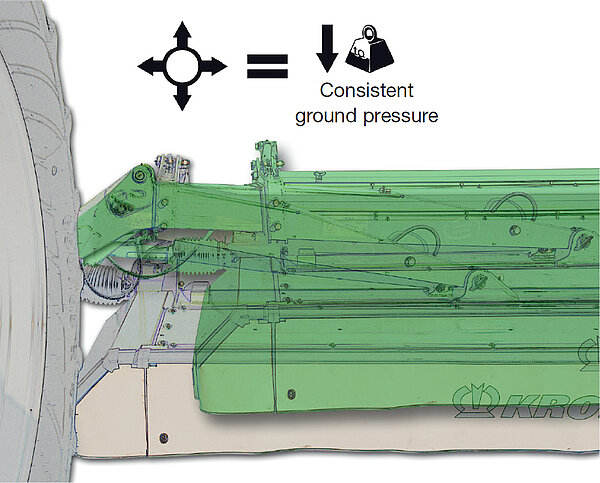

- KRONE Combi Float: Uniform bearing pressure across the entire work width

- EasyCut B 870 CV/CR and B 1000 CV/CR Collect

Product video

EasyCut B – KRONE mower combinations

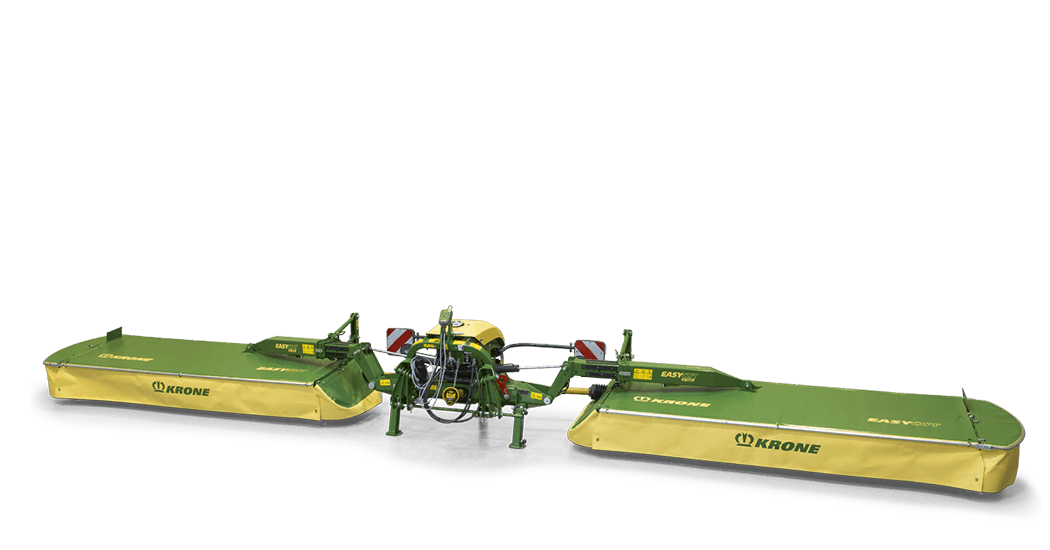

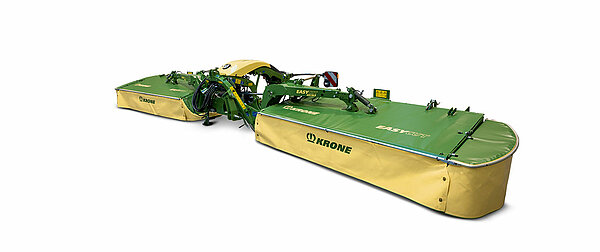

Introducing the new EasyCut B 870 and EasyCut B 1000, KRONE adds two models to its range of butterfly combinations. Compared with the previous butterfly mowers without conditioners, the new models stand out for a modern design and curved styling, taut curtains and an optimised weight thanks to a new headstock.

Mowing with maximum efficiency

NEW: EasyCut B 880 CV/CR (Collect) | B 1050 CV (Collect)

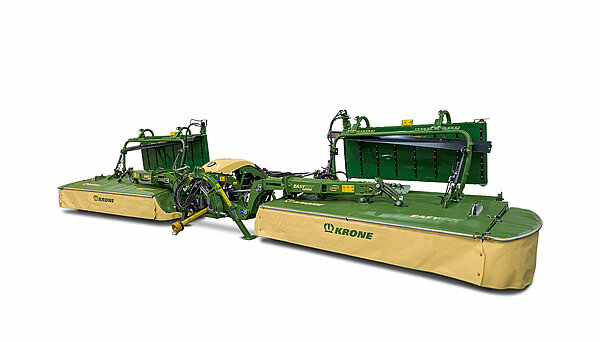

With the EasyCut B 880 CV/CR (Collect) and B 1050 CV (Collect), KRONE presents two new and highly efficient Butterfly combinations. They come with conditioners as a standard feature and can optionally be equipped with cross conveyor units.

Learn more

Product features

- KRONE SmartCut: Stripe-free cutting

- KRONE quick-change blades

- KRONE SafeCut: Individually protected cutting discs

- EasyCut B 870 and B 1000 without conditioner

- EasyCut B 950 Collect without conditioner, with auger conveyors

- EasyCut B 880 and B 1050 CV/CR Collect

- EasyCut B 1050 CV: With BiG Swath System

- KRONE Combi Float: Uniform bearing pressure across the entire work width

- EasyCut B 870 CV/CR and B 1000 CV/CR Collect

With innovative technology and excellent performance, the EasyCut B mowers set new standards in terms of efficiency. Whether dense grass, high field forage or difficult meadows – the EasyCut B models are up to every challenge. They perfectly adapt to the ground conditions and reliable follow the contour. The result: Even cuts without any compromise.

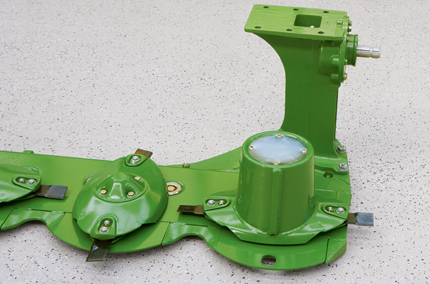

- Fully welded cutterbar: Robust, sealed and permanently lubricated

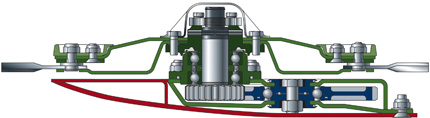

- Durable satellite drive with large spur wheels: Very quiet running and optimum power transmission

- Without inner shoe for trouble-free mowing

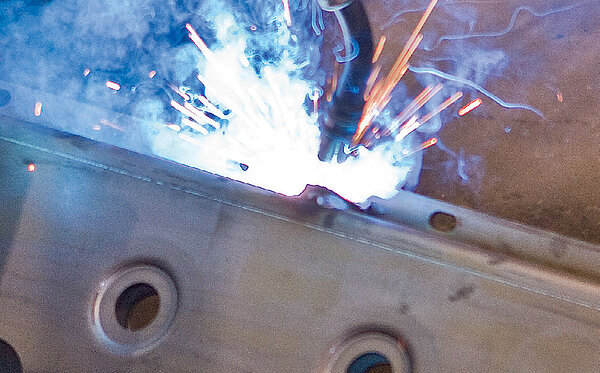

The completely welded cutterbar meets the highest quality standards, will remain leaktight and retain its shape even after long-term use. The large, oil-immersed spur wheels withstand sustained peak loads and are particularly quiet during operation.

Permanently lubricated: The completely welded cutterbar is maintenance free and won’t leak nor lose shape even in so many years of work. We give it special cleanings throughout the manufacturing process so we can implement permanent lubrication and eliminate the need for oil changes.

Leak-proof and robust: Using welding robots and CNC technology, KRONE manufactures its cutterbars to the highest quality standards, ensuring they are fully welded and permanently lubricated. After all, the cutterbar is the heart of every disc mower.

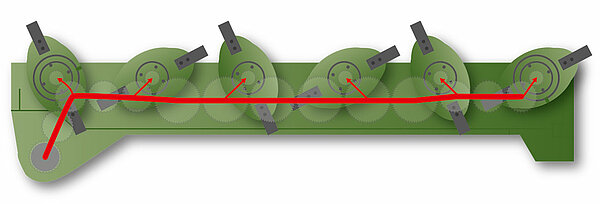

The satellite drive in the cutterbar – developed by KRONE and successfully used worldwide for decades: Large spur wheels with up to 59 teeth transmit the main drive forces to the end of the cutterbar. The large-diameter gears rotate at reduced speeds, with a higher number of teeth meshing with the neighbouring spur wheels. This design stands out for quiet running, maximum power transmission and a long service life. Each disc is driven by its individual auxiliary gear which minimises the load on the disc.

No inner shoe: The cutterbar is driven by the right-angle gearbox just behind the inner top hat for blockage-free operation on the headland and in awkwardly shaped fields.

- The wedge-shaped cutterbar guarantees clean cuts

- Heavy-duty spur gears run in double bearings

- Widely spaced bearings

- Swathing or wide spreading depending on needs

The wedge-shaped cutterbar offers great flexibility to adjust through a large range of settings and leave a short stubble in meadows and pastures as well as long stubble in long-stemmed forage crops. An EasyCut mower delivers a reliable performance and clean cut.

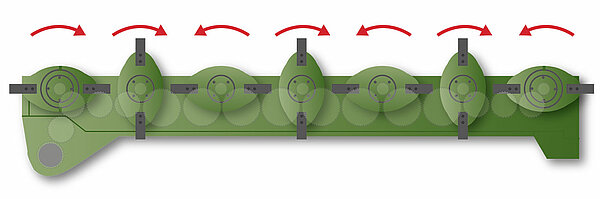

With discs spinning in the B direction of rotation, EasyCut spreads the crops across the full width. All discs turn in pairs in alternating directions, spreading the material across the working width for faster and more uniform wilting.

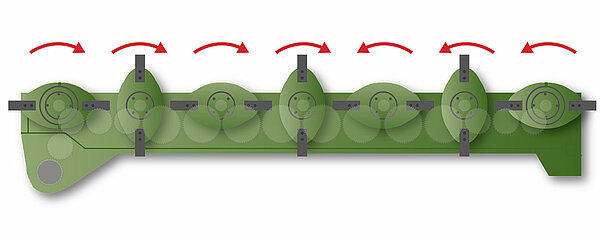

To prevent the mown forage from being run over by the tractor wheels, the bearing housings are positioned so that the discs rotate towards the centre.

Convenient: The spur gears are arranged in a forward position and eccentrically inside the gearbox right under the discs. The small auxiliary spur gears are removed from above, the massive main gears gearbox from the side.

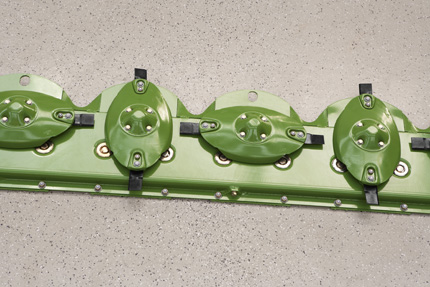

SmartCut: With some discs turning in pairs towards each other and others turning away from each other, it was necessary to redesign the degree of blade overlap to ensure cleanest cuts. For stripeless cuts in light and young crops, we have therefore increased blade overlaps on the discs turning outwards. In addition, the blades turning to the rear are set further apart to encourage a smooth flow of large volumes of crop..

The wedge-shaped cutterbar offers many height setting options. The spur gears run in massive double bearings, allowing the cutterbar to handle extremely high loads.

- Quick-change blades are standard specification, allowing operators to swap blades in the field quickly

- Modular disc design

- Minimum blade wear: 360° blade Action

- Excellent cuts from SmartCut: Optimum blade overlap

There are many reasons for choosing an EasyCut disc mower. Just think of the quick-change blades, the inexpensive wear parts and the perfect disc arrangement for stripeless cuts.

Cost saver: Worn blade fixing pins and wear parts are not an issue for KRONE EasyCut, because the modular design of the discs allows you to replace them individually. If you like, you can opt for bolts instead of pins.

Clean cuts: Blades of 112 mm length orbit with a generous overlap, producing the typically clean cuts and feeding the material to the rear in a consistent flow.

Minimised wear: The blades are free to spin 360° on their pins. They are hard-wearing and self-cleaning, well protected and will not foul with the blades on the neighbouring discs.

Added protection: We welded curved stops between the individual skids that protect the cutterbar from damage and also contoured the underside of the stops in such a way that no material can build up here and instead flows smoothly to the rear.

Making higher cuts: High-cutting skids are the solution for those who want 80mm and longer stubble. Depending on how you bolt the skids to the cutterbar, you can increase the cutting height by 30 mm or 50 mm, which is ideal in forage and whole crop silage.

Hovering over the sward: Made from hardened steel, the extra wide skids reduce the ground pressure and hence offer effective protection of both the cutterbar and the sward. The skids are bolted to the cutterbar so they are easy to replace.

Changing blades in an instant: Quick-change blades are a must for many farmers and contractors, These blades are quick and easy to reverse or replace in situ.

- Fully protected drives for greater reliability

- No collision with neighbouring cutting discs

- Wear-free

- Quick-change roll pins for minimum downtime and costs

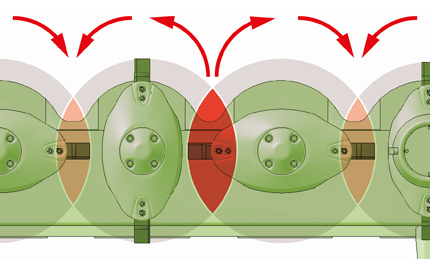

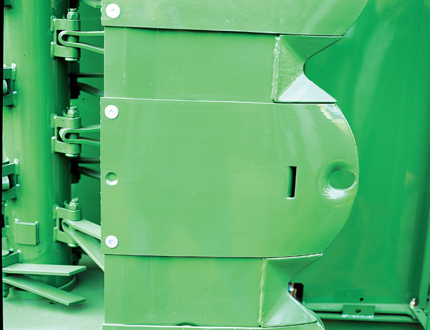

Colliding discs may cause damage and involve costly repairs. KRONE SafeCut offers maximum protection. The award winning system on all EasyCut models offers a unique level of protection and operator comfort. SafeCut is part of the basic equipment of all EasyCut F series disc mowers.

Effective and safe: If the system is suddenly overloaded, the impact is not directed to the spur gears in the driveline, instead a roll pin in the sprocket drive shaft shears off. The pinion shaft continues spinning, jacking up the disc in question, moving it out of the risk zone and the orbit of the neighbouring discs. As a result, SafeCut prevents damage to the spur gears and the neighbouring discs. Replacing the roll pin takes a few minutes and is not very costly.

Each disc on the mower has its own individual impact protection. When the blade hits an obstacle the shockload is transferred to a roll pin which breaks. As a result, the disc automatically threads 15 mm up on the drive shaft.

An ideal system: There is no load on the roll pins during operation. The bearing is tensioned by a nut and two clamping screws. As a result, the roll pins do not suffer from material fatigue and even after many hours of operation they will break only at their inbuilt load level.

Two-fold protection: Orbiting within the sphere of the mower bed and never protruding beyond the skids, the EasyCut discs benefit from two-fold protection. Additional protection comes from the standard SafeCut system.

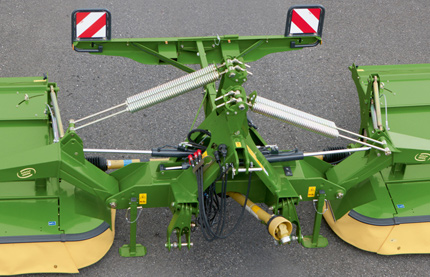

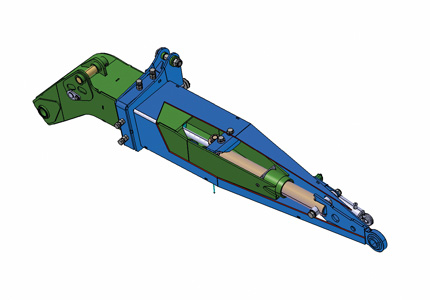

- Patented DuoGrip attachment of the cutterbar: Mounted in the centre of gravity and controlled by parallel arms

- Uniform bearing pressure across the entire work width

- Optimum guidance: Less side pull, clean cuts

- Continuous suspension for superb contouring and sward protection

The KRONE DuoGrip suspends the EasyCut mowers in their centre of gravity and guides them with suspension arms. This design allows the cutterbar to follow the ground contours even more accurately for a better protection of the sward. and high-quality forage even in difficult conditions.

Suspended in its centre of gravity: Maintaining a uniform pressure across the entire work width is a requirement that is thoroughly met by KRONE disc mowers, courtesy of the gearbox that is arranged on the inside of the machine where it shifts the centre of gravity to the side. This, the short arm and two extra braces give maximum stability while keeping the weight down – and delivering best results in rough going.

Accurate setup: For optimum mower control, position the tractor’s lower links in such a way that the two control arms on the mowers are level. The red arrow indicates the correct height of the lower links.

Strong: The mower is mounted on a pin which pivots in a ball bearing at the end of the outrigger arm. This design provides plenty of movement and exemplary contouring. In addition, the headstock features a standard and integral break-back system for effective impact protection.

Spreading the load: The parallelogram linkage absorbs lateral forces and guides the unit in direction of travel. At the same time, it helps reduce the load on the jib and the suspension system in the machine’s centre of gravity.

- V-shaped steel tines at steep angles give intensive and perfect conditioning

- The driveline dispenses with belts for frictional and low-maintenance Connections

- Great operator comfort from mechanical conditioner gearbox

- Adjustable baffle plates for enhanced conditioning

Efficiency is one parameter in hay and forage harvesting, quality is another. The high-performance KRONE CV conditioner with V-shaped steel tines spreads the crop at the full working width. The 640 mm diameter rotor and the helical arrangement of the tines warrant a continuous crop flow, high throughputs and superior conditioning.

The optional deflectors adjust to one of two spreading positions. You either form the material into narrow swaths on wet and boggy terrain or spread it across the work width for faster wilting.

The mechanical gearbox: Select 900 rpm for intensive treatment and 600 rpm for less intensive conditioning. Setting the speed is easy from the mechanical gearbox.

The tine-to-counter sheet clearance is adjusted by a continuous notch system and presents another option to alter the degree of treatment. As you reduce the gap you increase the intensity of conditioning.

The V-shaped steel tines on each mower span across the entire work width and from the left to the right drum, providing a uniform crop flow across the full width and of course optimum conditioning. Guide plates are available for wide spreading and even faster conditioning.

The v-tines are made from hardened steel and mount at a steep angle, treating the forage intensively and powerfully. The tines pivot to the rear when hitting a foreign object whereas their restricted forward angle increases the pivot pin‘s lifetime.

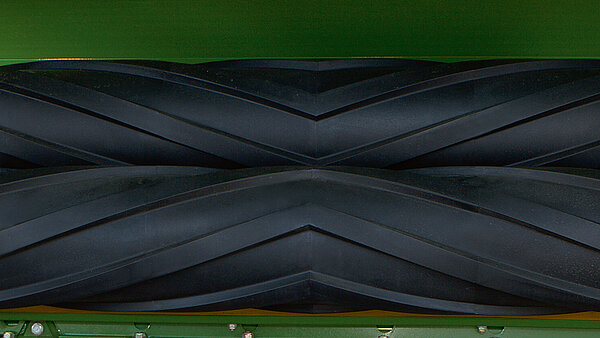

The roller conditioner models (polyurethane rollers or M-Rolls)

- The roller conditioner models (rubber rollers or M-Rolls)

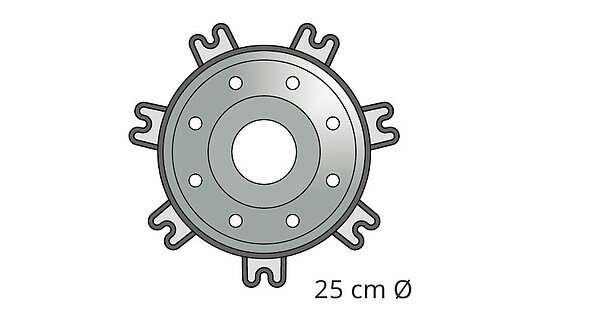

- Consistent crop flow by 25 cm diameter rollers

- High throughput from powered crop processor rollers

- Top quality from profiled rollers – thanks to their ‘meshing effect’

- Choice of roller conditioners – polyurethane rollers or steel M-Rolls

Leafy crops like Lucerne or clovers require a different type of conditioning than crops that are predominantly grass. The CR roller conditioners give particularly gentle treatment, leaving the delicate leaves intact which are so rich in protein and safeguarding the value of the feed. Spreading the crop will speed up wilting.

The counter-rotating M-Rolls mesh to crush the material and yet leave a sufficiently wide gap for the material to pass through. The result is a uniform conditioning quality for uniform wilting and no fragmentation – the perfect system for lucerne, for example.

The top roll of the M-Rolls is driven by a separate gearbox on the right end of the cutterbar which synchronizes the speed of the top and bottom rolls, bracing you for wet and heavy crops.

The large-diameter CR conditioner rotors deliver a smooth and consistent flow of crop and have a low power input.

Full-width application: The full-width CR rollers ensure a uniform conditioning effect across the entire work width And the rubber coating ensures maximum longevity. The interlocking surfaces of the rollers give intensive but gentle conditioning whilst avoiding losses.

The top roller suspends from a spring which ensures a continuous flow in inconsistent growth and allows foreign objects to pass the system trouble-free. Thanks to a stepless adjustment system, the operator adapts the gap and pressure steplessly to current yields. Frictional connections: The conditioning rollers are driven by gearboxes. The box that drives the bottom roller is integrated in the gearbox that powers the cutterbar.

- Variable swath width by means of optional accelerator rollers

- Tractor-independent oil supply through on-board hydraulic system

- Automatic activation and deactivation of the cross conveyor belts

- Divided conditioner tray for loss-free crop transfer

- Extra wide 910 mm cross conveyor belts handle large volumes of crop

The KRONE Collect system offers multiple setting options suitable for the most diverse applications around the world. The KRONE Collect cross conveyor belts deliver clean and perfect swaths that are easily picked up by the following harvesters for loss-free harvests.

The swath width of the EasyCut B CV and CR Collect can be preset by means of a hole pattern. The fine adjustment in keeping with the harvesting conditions is made via the belt speed and the optional accelerator rollers.

Powerful hydraulic rams raise the merger belts reliably – either in synch or independently.

Adjustable swathing boards: Adjustable swathing boards optimize the crop flow and the crop feed to the belts.

The merger belts are driven by an on-board hydraulic system which is cooled by a separate oil cooler.

Electric swath width adjustment: Operators of ISOBUS-compatible EasyCut B 1000 CV Collect and B 1000 CR Collect mowers adjust the swath width electrically by altering the belt speed and the height of the optional accelerator rollers. The option of electric motors offers great operator comfort.

The conditioners on EasyCut B 870 CV Collect and B 1000 CV Collect have curved deflector plates that guide all the material to the merger belts – nothing gets lost.

- Variable, up to 10.00 m work widths on EasyCut B 1000

- Weight-optimized headstock reduces rear axle weight and ground pressure.

- Adjustable non-stop impact damage protection system is a standard feature

- SmartCut and SafeCut ensure perfect cuts and maximum uptime

- Hydraulic suspension as a standard feature

In the EasyCut B 870 and B 1000, KRONE is presenting two powerful mower combinations that feature sophisticated technology and state-of-the-art design. With its optimised weight and hydraulic relief, the headstock not only protects the turf but also allows for use of smaller tractors.

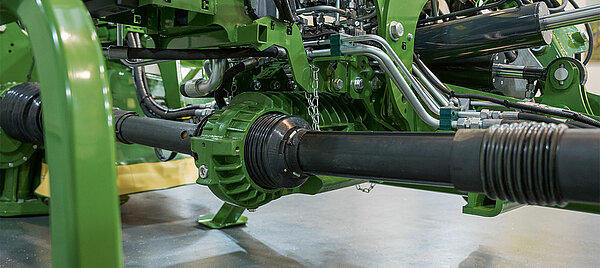

The mower combination is powered by a 1,000 rpm pto. The main gearbox in the middle splits the powerflow and sends it to the downstream pto shafts. The driveline is protected by break-back systems and overrunning clutches.

The mower combinations have a standard non-stop break-back system that offers an infinitely variable trip force set on a coil spring. When the machine hits an obstacle the system trips immediately and the mower swings up to 1.60 m rear and upwards. Once the obstacle has been passed the cutterbar moves automatically back into work position.

The headstock is protected by a new cover. The befitting curtains on the mower decks are thin and taut, reducing the build-up of material and protecting the cutterbar from damage by stones.

The weight-optimised headstock is coupled in the three-point linkage with three-fold buttressed pins, a design that moves the centre of gravity closer to the tractor, enabling the use of smaller tractors.

- The outrigger arms adjust to two positions (EasyCut B 870) or infinitely variably (EasyCut B 1000) to provide optimum overlapping

- Optimum overlapping eliminates striping in curves and on slopes

- Hydraulic bearing pressure control conveniently from the cab

EasyCut B 870 and B 1000 are no-compromise machines. The infinitely variable arm length control adapts mower unit overlaps to the current conditions without compromising on acreage and output.

The DuoGrip centre of gravity suspension allows all mowers in the combination to maintain a consistent ground pressure across the entire working width. You simply set the pressure hydraulically from the cab. It is then indicated on the pres-sure gauge. The system delivers optimum contouring and perfect cuts.

The independent machine lift-out feature, a standard spec-ification, makes it easy to cut awkward corners. Simply select the specific mower on the control box and then raise it hydraulically.

EasyCut B 1000 operators set front-rear overlaps on the move and infinitely variably on the cab-based terminal. At the same time, they can vary the distance between the other rear mowers between 2.08 m and 2.80 m. When combining this model with a 3.16 m front mower, the overlap on both sides ranges from 18 cm to 59 cm. This allows opera-tors to adapt the combination flexibly to current conditions and maintain high work rates and a clean cut.

EasyCut B 870 offers two attachment positions for the mower arms which allow operators to set the distance between the two mowers to 1.99 m, which is helpful in sloping fields and curved passes. In combinations with a 3.16 m front mower, this setup leads to 59 cm overlaps and a total work width of 8.31 m. In flat fields and straight passes, however, you can extend the mower-to-mower distance to 2.30 m, which reduces the overlap to 43 cm and increases the total work width to 8.62 m thereby maximising productivity.

- Safe road travel thanks to 95° transport angle. Less than 4 m transport height and 3 m width.

- Compact storage position on sturdy support jacks

- LED lights and reflecting warning panels are standard specification

The carefully designed folding mechanism makes for a compact storage position. Road travel is safe, too thanks to the compact transport dimensions.

You can select various machine functions from the control box. These are then executed by the tractor’s hydraulic system. This technology requires only a single-acting and a double-acting spool.

LED lights at the rear and a brake light with an integral red-white reflector panel provide adequate road safety.

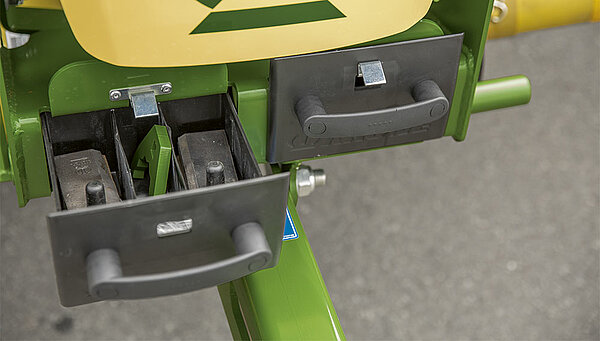

These removable drawers are standard specification on the mower combination. Here you store your spare blades to have them readily at hand. The blades are quick-change as standard.

The mowers fold into a 95° transport position, slightly leaning to the middle. The end curtains drop automatically into transport position as the units fold into the vertical.

Hydraulic check valves lock and re-lease the mowers automatically when these are moved into work or transport position.

Measuring only less than 4m high and less than 3m wide, these mower combinations absorb very little stor-age space. They are parked on sturdy stands. Extra stability on the EasyCut B 1000 comes from an outrigger on the cutter-bar and hoop guards (option on Easy-Cut B 870).

- Light-weight and compact mower combination without conditioners

- 9.45m working width including front mower

- Massive auger conveyors merge the swaths

- Three swathing modes are selected from the cab: individual swathing, partial width swathing and wide spreading

- Hydraulic mower suspension controlled from the cab

The EasyCut B 950 Collect is a very compact mower combination that has auger conveyors but no conditioners. The massive augers merge large volumes of crop such as green rye into a uniform and clean swath.

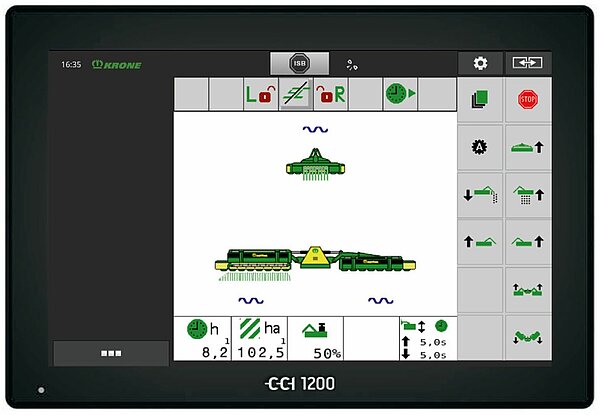

[Translate to EN:] Mithilfe der optionalen ISOBUS-fähigen Komfortbedienung können die Funktionen des Mähwerkes über die traktoreigenen Terminals sowie das DS 500, CCI 800 oder CCI 1200 mit Touchscreen intuitiv und komfortabel über Load-Sensing bedient werden.

[Translate to EN:] Beim EasyCut B 950 Collect lassen sich die hydraulischen Funktionen über das PreSelect DS 50 oder alternativ mithilfe des PreSelect Digital per Terminal vorwählen und werden dann über die traktorseitigen Steuergeräte ausgeführt.

For safe road transport, the curtains on the sides fold up automatically. The transport height is less than 4 m.

To minimize losses when working along field borders, opera-tors can switch between spreading and swathing – separately by mower, on the move and from the convenience of the cab. This will not change the mowers’ working position. Having one mower swath the crop is useful when opening a field and when cutting around obstacles. This option is also very useful in later cuts and in combination with a KRONE four-rotor rake.

A hydraulic crop deflector is available for those who seek even more uniform swaths. When the B 950 Collect moves from road position to headland position the crop deflector is sequence controlled into its horizontal working position. This option is particularly useful in wedge-shaped plots or when one mower is not swathing.

The EasyCut B 950 Collect mowers feature hydraulic suspension which allows operators to adjust contouring from the electric control box in the cab. The level of response is set steplessly and the current setting is indicated on a pressure gauge that is easily read from the cab – for best contouring even in very difficult conditions.

The standard combi skids increase the cutting height from 50 mm to 120 mm and allow operators to cut different crops like grass and green rye at different heights.

The mowers lift out separately as a standard feature: Operators can raise one mower when cutting wedges. Simply select the mower that is not in work on the electric control box and raise it.

The DuoGrip system suspends each unit in its centre of gravity and provides extra guidance by lateral arms for superior ground contour hugging. The rear lights can be raised hydraulically as an option to clear the way for more material to pass through this area. Lowered into transport position, they increase road safety.

The sturdy 45 cm diameter cross augers are powered by a right-angle gearbox and revolve at a consistent speed of 750rpm, giving maximum efficiency and productivity. Arranged closely behind the cutterbars, these augers feed large volumes of crop in a consistent flow from the mowers to the middle of the combination, forming a tidy and uniform swath that is cleanly gathered by the following harvesters.

The decks behind the augers open and close hydrauli-cally for convenient selection of one of the three swathing modes from the cab: swathing, independent swathing or no swathing.

- 8.70 m work width

- EasyCut B 870 CV with tine conditioner

- EasyCut B 870 CR with roller conditioner (rubber rollers or M-Rolls)

- A compensation rocker ensures the bearing pressure is uniform on either side

- A standard impact damage protection system gives effective protection

EasyCut B 870 CV and CR not only utilise the power of your tractor but also save time and costs. The EasyCut B 870 with conditioners and extra wide cross conveyor belts has a versatile range of applications. This machine enables you to cut, condition and spread or swath the material in one single pass.

Limiting the pivot range: Hydraulic rams limit the transverse travel of the mowers that suspend in their centre of gravity, giving plenty of ground clearance during the headland turn or travel on public roads.

Double-acting rams: Double-acting rams provide dependable control of each unit as it lifts and lowers on slopes whereas single-acting rams lift them into headland position.

Simple driveline: The driveline is simple and efficient. A main gearbox on the headstock splits the power and sends it to the side mowers.

A KRONE exclusive! The patented compensating rocker on the adjustable spring suspension system distributes the ground pressure evenly to both mowers. This feature guarantees cleanest cuts and forage, light pulling and protection of the valuable sward.

Convenient for operators: Holders on the machine store the oil hoses when the machine is removed from the tractor. The hose couplers have numbered handles for easier attachment and removal.

- High work rates from up to 10.10 m working widths

- EasyCut B 1000 CV with steel tine conditioner

- EasyCut B 1000 CR with an aggressive roller conditioner

- Hydro-pneumatic compensation for uniform ground pressures

- A standard break-back system gives effective protection

The EasyCut B 1000 CV and EasyCut B 1000 CR stand out for a huge 10.10 m work width and their powerful CV or CR conditioners. Another high-profile feature is the world-first Combi Float – the automatic and hydro-pneumatic control system.

Combi Float – a KRONE only: The speciality of this feature is the fact that it maintains the pressure inside the reservoirs of the hydro-pneumatic system – courtesy of extra spools and the circuit of the single-acting coupler with free return line. The advantage of this system is that it maintains a uniform suspension of both mowers in undulating terrain and when working at various work widths.

- It maintains a uniform bearing pressure in undulating terrain and with the mowers working in offset positions.

- The mower suspension is easily adjusted from the tractor seat – even on the move.

- A lightweight, hardwearing, easy-pulling and compact design.

An integral system: The compact headstock features integral rams, valve chest and accumulators to reduce its weight and hence the load on the tractor‘s hydraulics. It also features an easy-to-open cover for effective protection.

Adjustable and flexible: The responsive break-back system moves the machine reliably up and to the rear. It’s tripping force is set steplessly on the coil springs.

Fully protected: The standard impact damage protection system on EasyCut B 1000 CV and B 1000 CR gives you peace of mind as you cut along borders, fences and hedges and when the machine hits an obstacle. When one of the side mowers hits an obstacle it swings approx. 1.50 m to the rear and returns automatically into its working position once the obstacle is passed.

- Hydraulic overlap adjustment

- Large setting range of up to 40cm per side

- Cleanest cuts in bends and on slopes

The standard hydraulic side shift feature on the rear mounted mower eliminates any striping and maximizes efficiency. Cutting straight lines, the machine operates at the maximum width and minimum overlap, whereas larger overlaps and a narrow working width is selected when cutting curves. As you operate on the slope, simply retrieve a stored sideshift range to the right or left and avoid drifting and striping.

Flexible control The ISOBUS terminal allows operators to telescope the rear mowers hydraulically in and out, either in sync. or independently by up to 40 cm. In addition, the standard-fit terminal adjusts the work width simultaneously on both sides.

Optimum adaptation: The mower arms on the EasyCut B 1000 CV and B 1000 CR side mowers extend and retract on telescoping arms. As you shift the two mowers in opposed directions you alter the overlap relative to the front mower and the total work width. When using an EasyCut front mower of a 3.16 m work width, you can set overlaps from 130 to 530 mm on each wing. To avoid striping on slopes, shift the wings to the same side.

Hydraulic control: Double-acting rams inside the mower arms extend and retract the arms on the move to vary the degree of overlap.

- Convenient headland function by fingertip control

- Safe road travel: 4.00 m transport height and less than 3 m transport width

- Great operator comfort: Compact on the tractor, adjustable tractor-machine distance

- Minimum space requirement by storing in transport position

The side mowers are retract automatically so that the transport height of 4.00 m is not exceeded. An automatic transport locking system provides for safe road travel and is activated as the rear mowers are shifted to the middle.

Innovative steering: The wings are raised by compact double rams, which make machine operation easier for the operator. The single-acting rams lift the mowers to headland position; the double-acting rams fold them into transport position.

Automatic folding: For a reduced transport height the end guards on each mower fold up automatically as the machine folds up.

For all tractor back ends: All three mowers lift and lower at the touch of a button when the tractor approaches the headland. You can operate the front linkage from the valve chest on the rear combination. Cutting wedges or awkward plots is easy as you use one or two mowers. The machine is not running on cut material. EasyCut B 1000 CV not only delivers an exceptional performance in large fields but also in smaller plots, producing clean cuts and perfectly conditioned forage.

Store the side mowers on their sturdy stands in upright position and save space for more equipment in your shed.

- Extra wide cross conveyor belts for continuous flow even in high volumes of crop

- Each belts can be raised individually, providing one of the three swathing modes available: wide spreading, partial width swathing or single swathing

- Belts shut off and on automatically when raised and lowered

The Collect system with cross conveyor belts makes EasyCut B 870 CV and B 1000 CV with steel tine conditioners and EasyCut B 870 CR and B 1000 CR with roller conditioners versatile machines that spread the material across the working width or produce one central or two individual swaths. The powerful conveyor belts handle even the heaviest crops most effectively.

4. Boosting your efficiency: Using only one merger belt and reducing the spreading width saves costs and time and reduces compaction if followed by a KRONE four-rotor centre-delivery rake.

3. One mower is not swathing: In one up-and-down operation, EasyCut B 1000 CV groups up to 20.20 m of work into four swaths and 13.00 m – ideal for further swathing by a KRONE four-rotor centre delivery rake.

Cleared boundaries: Operate only one belt to clear the pass along the border so the following machines can work at greater ease.

1. No swathing: Raise the belts and spread the material across the full width. Spreading the material speeds up wilting and helps achieves target DM rates faster.

Central windrowing: The Collect System groups three passes into one – cutting, conditioning and windrowing, thereby reducing the number of passes and the degree of compaction as well as the damage to the turf and contamination of the crop.

Pumping out masses of material: Cutting whole crop silage requires powerful machines with plenty of clearance. The Collect mower combinations have nearly 1 m wide merger belts that merge even the highest volumes of crop to the middle. Depending on the crop growth and the desired shape of the swath, operators can adjust belt speeds hydraulically from the tractor seat.

- Compact design due to weight-optimised three-point hitch mounted close to the tractor

- Safe on the roads with a transport height under 4 m and a transport height under 3 m

- Small footprint in the yard: Machine is parked in folded-up position, held by support jacks (telescopic as an optional feature)

- NonStop impact damage protection system fully integrated in the headstock

- Maximum operational reliability thanks to KRONE SafeCut

- Most efficient Butterfly combination in the market: EasyCut B 1050 with 10.45 m working width, dimensioned for front mounted mowers with 3.2 m to 4 m working width

- Variable attachment in the EasyCut B 880 since headstock can be mounted in two different positions

The new KRONE mower combinations EasyCut B 880 CV and CR and EasyCut B 1050 CV convince with maximum safety and unsurpassed efficiency. The compact three-point headstock mounted close to the tractor provides for very comfortable driving. In case of contact with an obstacle, the NonStop impact damage protection system ensures fast, automatic swinging back of the mower unit, preventing damage to the machine.

[Translate to EN:] Beim Zusammenklappen des Mähwerks klappen die Seitenschütze automatisch ein. Mit einer Transporthöhe von weniger als 4 m bei ca. 25 cm Bodenfreiheit sowie einer Transportbreite von unter 3 m fahren Sie stets sicher auf der Straße.

[Translate to EN:] Nach dem Zusammenklappen der Mäheinheiten lässt sich die Maschine bequem und sicher auf optional teleskopierbaren Stützfüßen abstellen – eine sehr komfortable und platzsparende Lösung.

[Translate to EN:] Sowohl die neu designte Haube auf dem Anbaubock als auch die auf die Schutzrahmen der Mäheinheiten gespannten Tücher verringern mögliche Ablagerungen und schützen vor Steinschlag. Zudem sind sie leicht und bei Bedarf einfach austauschbar.

[Translate to EN:] Die im Heck mit einer rot-weiß reflektierenden Warntafel kombinierte LED-Beleuchtung fördert die Sicherheit auf der Straße. Während der Arbeit kann sie auf Wunsch einfach hydraulisch ausgehoben werden, sodass sie nicht mit dem Mähgut in Berührung kommt und stört.

[Translate to EN:] Serienmäßig verfügen die Mähkombinationen über eine Non-Stop-Anfahrsicherung mit stufenlos über eine Spiralfeder einstellbarer Auslösekraft. Diese lässt die Mäheinheit beim Auftreffen auf ein Hindernis schnell nach hinten und unten schwenken. Anschließend kehrt sie selbstständig in die Ausgangsposition zurück.

[Translate to EN:] Die Mähwerke werden über einen kompakten gewichtsoptimierten Dreipunktbock der Kategorie 2 oder 3 angebaut. Der Schwerpunkt liegt dicht am Schlepper. Unter der neu designten Haube befindet sich gut geschützt die aktiv regelnde hydraulische Entlastung.

- High acreage output

- EasyCut B 880 CV/CR with 8.53 m and 8.72 m working widths

- EasyCut B 1050 CV with 9.30 m to 10.45 m hydraulically adjustable working widths

- CV or CR conditioners: V-shaped steel tines, polyurethane rollers or M-Rolls

- Constant bearing pressure: Hydro-pneumatic compensation, conveniently controlled from the tractor, for uniform ground pressures

- Convenient operation thanks to actuation via electrical preselection box or ISOBUS terminal

- Efficient drive: via gearboxes and universal shafts to the mower units

- Re-designed main gearbox: for maximum displacement path of the mower units

With variable working widths of 8.72 m respectively 10.45 m, the mower combination EasyCut B 880 CV/CR and B 1050 CV are designed for maximum efficiency. Adjustable overlaps guarantee strip-free mowing in all fields. Choose from the range of V-shaped steel tines or roller conditioner to actively control the drying process. Controlled from the cabin, the infinitely adjustable hydraulic relief provides for optimum ground contouring.

[Translate to EN:] Das Ablageblech und somit der Winkel, in dem das Erntegut die Maschine verlässt, lässt sich einfach per Handkurbel verstellen. Gerade bei den Collect Modellen kann der Gutfluss der Maschine auf diese Weise optimal angepasst werden.

[Translate to EN:] Beim EasyCut B 880 CR sorgt der Walzenaufbereiter für eine intensive und zugleich schonende Aufbereitung, wie sie unter anderem in Klee und Luzerne erforderlich ist. Dabei wird das Mähgut von zwei gegenläufig ineinander greifenden Walzen gequetscht, ohne dass Bröckelverluste entstehen. Wahlweise stehen hierfür Polyurethan- oder Stahlwalzen zur Verfügung. Diese nennt man M-Rolls.

[Translate to EN:] Mithilfe verstellbarer Leitbleche lässt sich die Ablagebreite des Mähgutes so einstellen, dass kein Erntegut überfahren wird. So können Sie je nach Materialfeuchte und Witterung den Trocknungsverlauf gezielt beeinflussen. Zudem erlaubt diese Einstellbarkeit eine bessere Abstimmung der nachfolgenden Arbeitsschritte.

Use the crank handle to change the distance between tines and baffle sheet, and thus the conditioning intensity. You can also control the intensity by setting the rotational speed of the conditioner via manual gearbox to 900 or 600 rpm.

[Translate to EN:] Mit insgesamt vier leistungsstarken LED-Lampen – zwei am Auslegerarm und zwei am Anbaubock – wird jeder Arbeitsbereich optimal ausgeleuchtet. Das besonders helle Licht ermöglicht eine hohe Produktivität selbst bei Dunkelheit. Die LED-Arbeitsbeleuchtung ist bei den neuen Butterfly Kombinationen optional erhältlich.

[Translate to EN:] Die Mähkombinationen EasyCut B 880 CV (Collect) und B 1050 CV (Collect) sind mit auf Griff stehenden Stahlzinken ausgestattet. Diese bereiten das Mähgut auf ganzer Maschinenbreite intensiv auf und beschleunigen so den Trocknungsprozess. Die CV Zinken von Krone sind für ihre Langlebigkeit, Robustheit und Leistungsfähigkeit bekannt. Der große Durchmesser und das serienmäßige Aufbereitergetriebe sorgen für einen homogenen Trocknungsverlauf.

[Translate to EN:] Alternativ zu den serienmäßig verbauten Gleitkufen stehen optional Kombi- und Hochschnittkufen mit Schnellwechselsystem zur Verfügung. Damit lässt sich die Schnitthöhe auf 50 mm bis 120 mm einstellen, um auch Ackergras und GPS-Bestände bei idealer Stoppelhöhe zu mähen.

[Translate to EN:] Das mittig angeordnete und mit einer Zapfwellendrehzahl von 1000 U/min angetriebene Hauptgetriebe ermöglicht einen schonenden Gelenkwellenverlauf zu den seitlichen Mäheinheiten. Überlastkupplungen und Freiläufe schützen das Mähwerk und den Traktor vor möglichen Schäden. Die Triple Tube Gelenkwellen ermöglichen beim EC B 1050 CV Collect die maximale Arbeitsbreite von 10,45 m.

[Translate to EN:] Die Ansteuerung kann bei den EasyCut B 880 CV und CR (Collect) über die neue Vorwahlbedienung PreSelect oder auf Wunsch bei den EasyCut B 880 CV und CR Collect noch komfortabler per ISOBUS erfolgen. Die EasyCut B 1050 CV (Collect) sind serienmäßig mit der ISOBUS-Komfortbedienung erhältlich.

[Translate to EN:] Beide Mäheinheiten werden durch das Lenkersystem DuoGrip im Schwerpunkt getragen und von Lenkern seitlich geführt. Per Bedienbox oder ISOBUS-Terminal lässt sich der am Manometer ablesbare Auflagedruck vom Traktor aus einstellen hydraulisch einstellen. Das sorgt auch unter schwierigen Bedingungen für eine optimale Bodenanpassung und beste Konturführung.

[Translate to EN:] Beim EasyCut B 1050 CV (Collect) lässt sich die Arbeitsbreite über die teleskopierbaren Auslegearme hydraulisch von 9,30 m bis 10,45 m variabel verstellen. In Kombination mit einem EasyCut F 360 CV lässt sich so je nach Beschaffenheit der Fläche ein Überschnitt von rund 75 cm bis 18 cm, bei Einsatz eines EasyCut F 400 CV Fold ein Überschnitt von 97 cm bis 40 cm realisieren. Auf diese Weise erzielen Sie stets einen extrem sauberen Schnitt bei höchstmöglicher Flächenleistung. Ein EasyCut F 320 kann ebenfalls kombiniert werden.

[Translate to EN:] Beim EasyCut B 880 CV und CR (Collect) lassen sich die Auslegearme der Mäheinheiten mechanisch auf eine Arbeitsbreite von 8,52 m oder 8,72 m einstellen. Je nach verwendetem Frontmähwerk lässt sich der Überschnitt an die jeweiligen Bedingungen anpassen. In ebenem und kurvenarmem Gelände erzielt man mit der höheren Arbeitsbreite eine maximale Flächenleistung. In Hanglagen oder auf konturreichen Schlägen erreicht man mit der geringeren Arbeitsbreite mehr Überschnitt für eine streifenlose Mahd.

[Translate to EN:] Die heckseitig angelenkte Schwadklappe lässt sich stufenlos verstellen, um über einen perfekten Gutfluss eine optimale Beschickung der Querförderbänder zu gewährleisten. Die geteilte Aufbereiterwanne sorgt zudem für eine verlustfreie Gutübergabe auf das Querförderband.

[Translate to EN:] Eine an das Hauptgetriebe angeflanschte Ölpumpe betreibt die eigene Bordhydraulik der Maschine. Diese versorgt die 910 mm breiten Querförderbänder und entlastet die Schlepperhydraulik.

[Translate to EN:] Das Mähen mit nur einem Querförderband bietet sich beispielsweise zum Räumen von Feldrändern an, wo es ein sicheres Arbeiten nachfolgender Maschinen ermöglicht. Des Weiteren lassen sich so bei paralleler Hin- und Rückfahrt durch die damit verbundene schmalere Ablage bei nachfolgendem Einsatz eines Vierkreisel-Mittelschwaders Kosten durch weniger Arbeitszeit einsparen. Zudem trägt diese Arbeitsweise zur Entlastung des Bodens bei.

[Translate to EN:] Die Mähkombinationen EasyCut B 880 CV/CR Collect und B 1050 CV Collect sind jeweils mit zwei Querförderbändern ausgestattet. Diese fördern selbst große Futtermassen, wie sie beispielsweise in GPS-Beständen anfallen, sicher zur Mitte. Dabei erledigen sie gleich drei Arbeitsgänge in nur einem Schritt: Mähen, Aufbereiten und Schwaden.

- EasyCut B 1050 CV with BiG Swath System as accessories kit

- With CV conditioner and with swath merging system by means of auger conveyor

- 9.30 to 10.45 m working widths

- Wide spreading, partial width swathing or central swathing

- 45 cm diameter of the auger conveyors – reliable also with large forage volumes

With the KRONE EasyCut B 1050 CV BSS, swath merging can optionally also be effected by means of auger conveyors – an option unparalleled in other Butterfly combinations. Large-dimensioned augers behind the CV conditioner ensure gentle crop flow without losses. Depending on the hood position, the crops are spread centrally or deposited in partial-with swaths or individual swaths. This technology, which has been tried and tested thousands of times on the BiG M self-propelled machines, is now also being used on the Butterfly combinations.

[Translate to EN:] Der Antrieb der Querförderschnecken befindet sich an den Außenseiten der Mäheinheiten. Durch diese Platzierung wird ein reibungsloser und effizienter Gutfluss gewährleistet, sodass das Material problemlos in das Schwad gefördert werden kann, ohne dabei behindert zu werden. Die außenliegende Anordnung des Antriebs trägt zudem zu einer optimalen Gewichtsverteilung und Stabilität der EasyCut B 1050 CV Butterflykombination bei.

[Translate to EN:] Das KRONE BiG Swath System ist optimal für die Ernte von Ganzpflanzensilage (GPS) geeignet. Es ermöglicht eine saubere und vollständige Zusammenführung des gesamten Pflanzenmaterials in einem breiten Schwad. Die Querförderschnecke gewährleistet einen schonenden und verlustfreien Transport des Ernteguts, vom Aufbereiter bis in das Schwad. So wird eine erstklassige Futterqualität erreicht.

[Translate to EN:] Durch die effiziente Zusammenführung des Ernteguts zu einem besonders breiten Schwad wird die Aufnahme und Verarbeitung durch den Häcksler optimiert. Das Ergebnis ist eine gesteigerte Produktivität bei der Grünfutterernte.

[Translate to EN:] Die Schwadhauben lassen sich bequem von der Kabine aus öffnen und schließen. Mit nur einem Tastendruck kann das Mähgut entweder breit verteilt, einseitig abgelegt oder zur Mitte hin gefördert werden. Durch die großzügig zu öffnenden Schneckenhauben wird das Futter locker und gleichmäßig abgelegt.

[Translate to EN:] Mit dem optional erhältlichen BiG Swath System (BSS)wird das EasyCut B 1050 CV mit groß dimensionierten Querförderschnecken von 45 cm Durchmesser ausgestattet. Durch die hydraulisch teleskopierbaren Auslegearme lässt sich der Überschnitt zum Frontmähwerk sowie die Breite des Schwads flexibel an die jeweiligen Bedingungen anpassen.

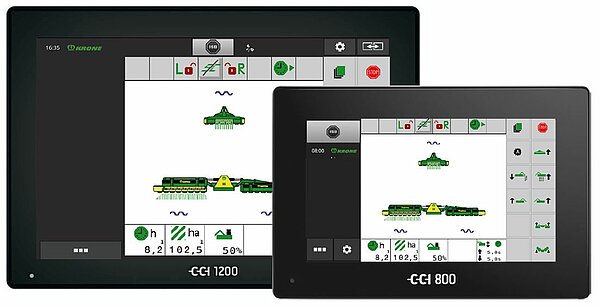

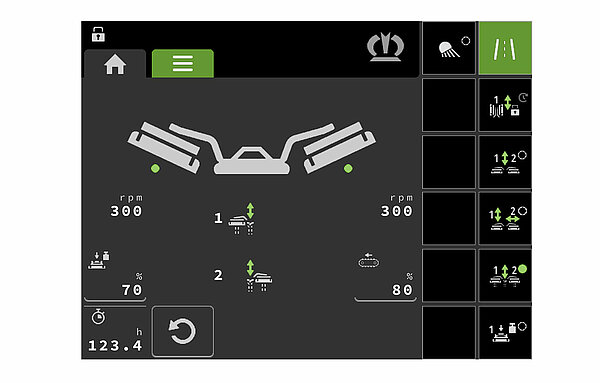

- Convenient for operators

- Clear concept

- Easy

The Butterfly combinations EasyCut B 880 CV and CR Collect, B 950 Collect and B 1000 CV and CR (Collect) are available either with the electrical PreSelect operation or the ISOBUS Comfort control unit, which is the standard for the EasyCut B 1050 CV (Collect). The ISOBUS-compatible devices comprise a large choice of terminals and intuitive-use control units. SectionControl, the new CCI 1200/800 and the tried and tested AUX joystick CCI A3 are just two examples of what’s available.

[Translate to EN:] Der AUX-Joystick CCI A3 erleichtert die Bedienung und optimiert den Bedienkomfort. Da die Icons der Funktionen direkt auf dem Touchscreen des Joysticks angezeigt werden, hat der Fahrer stets den Überblick über die Bedienung der Maschine. Durch die austauschbaren Rahmen wird die Anordnung der Tastenfelder optimal an den jeweiligen Einsatz angepasst.

[Translate to EN:] Bei den Bedienterminals CCI 800 und CCI 1200 sorgt ein 8“ bzw. 12“ großer Touchscreen mit Farbdisplay für höchsten Komfort. Neben der Hauptfunktion auf maximaler Größe werden gleichzeitig weitere Funktionen im Mini-Viewer angezeigt. Zusätzlich können diese Terminals mit Kameras, AUX-Joysticks sowie der Lizenz für SectionControl kombiniert werden.

[Translate to EN:] Die EasyCut B 880 CV und CR Collect, B 950 Collect und B 1000 CV und CR Collect können mithilfe der optionalen ISOBUS-fähigen Komfortbedienung über die traktoreigenen Terminals sowie das DS 500, CCI 800 oder CCI 1200 mit Touchscreen intuitiv und komfortabel über Load-Sensing bedient werden. Bei den EasyCut B 1050 CV (Collect) ist die Komfortbedienung bereits serienmäßig enthalten.

[Translate to EN:] Mithilfe von KRONE PreSelect Digital können die Vorwahl der Funktion und die Betätigung des Steuergeräts über die AUX-Tasten des ISOBUS-fähigen Fahrhebels des Traktors ausgeführt werden. So können alle Traktor- und Maschinenfunktionen bequem auf einem Joystick ohne Umgreifen bedient werden.

[Translate to EN:] Das KRONE PreSelect Digital erfüllt grundsätzlich die gleichen Aufgaben wie das KRONE PreSelect DS 50. Der Unterschied besteht darin, dass durch die Kabelverbindung zwischen Anbaugerät und ISOBUS-Steckdose des Traktors die Ansicht und Vorwahl auf einem ISOBUS-Terminal ausgeführt werden. Es besteht die Möglichkeit, zwischen dem PreSelect DS 50 und PreSelect Digital zu wechseln. PreSelect ist verfügbar für B 870, B 1000, B 880 CV/CR (Collect) und B 950 Collect.

[Translate to EN:] Mit dem KRONE PreSelect DS 50 werden hydraulische Funktionen der angeschlossenen Anbaugeräte vorgewählt und anschließend mit den traktorseitigen Steuerventilen betätigt. Elektrische Funktionen wie der Auflagedruck der Mähwerke werden direkt angezeigt und sind über Tasten anzupassen. Der Anschluss erfolgt über eine Direktverbindung zur Schnittstelle der Maschine und wird über einen 12V-Stecker in der Kabine mit Spannung versorgt.

SectionControl: The EasyCut B 1000 CV/CR Collect mowers are also available with SectionControl. This feature switches the individual sections from headland to working position and vice versa – automatically and with the optimum timing, reducing operator strain and maximizing productivity.

- Autonomous telemetry unit thanks to solar panel and rechargeable battery

- Automatic data acquisition in real time

- Data transmission to KRONE Smart Telematics and agrirouter

- Can be used flexibly on all machines (regardless of the manufacturer)

- Especially for machines without own electronics as well as rental machines

The KRONE SmartConnect Solar telemetry unit is completely autonomous thanks to the solar panel and rechargeable battery. This means that the box can be used flexibly on all machines, regardless of the manufacturer. The following data is sent by the SmartConnect Solar in real time: the position, the speed, active and inactive operating hours, the distance travelled, the working and transport position, the number of loads or the worked area and the charge status of the rechargeable battery. The machine data is recorded in real time and automatically transmitted to KRONE SmartTelematics or the agrirouter.

The position sensor can detect the working position (active) and transport position (inactive) by the alignment of the SmartConnect Solar. With a stored working width, the SmartConnect Solar can also be used as a hectare counter. Alternatively, it is possible to record the loads on transport vehicles by opening/closing the tailgate.

As the KRONE SmartConnect Solar has an autonomous power supply and can be mounted regardless of the manufacturer, it is ideal for use on rental machines. In this way, you always know where your rented machine is. The precisely documented working hours and acreage output enable transparent and accurate invoicing of the rental machines.

[Translate to EN:] Mit dieser autarken Telemetrieeinheit können auch einfache Maschinen wie Mähwerke, Wender, Schwader sowie andere Geräte ohne eigene Elektronik in ein digitales Datenmanagement eingebunden werden.

Models

| EasyCut B 870 | EasyCut B 1000 | EasyCut B 950 Collect | EasyCut B 870 CV | EasyCut B 870 CV Collect | EasyCut B 870 CR | EasyCut B 870 CR Collect | EasyCut B 880 CV | EasyCut B 880 CV Collect | EasyCut B 880 CR | EasyCut B 880 CR Collect | EasyCut B 1000 CV | EasyCut B 1000 CV Collect | EasyCut B 1000 CR | EasyCut B 1000 CR Collect | EasyCut B 1050 CV | EasyCut B 1050 CV Collect | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Working width (m) | 8.31 - 8.62 | 9.28 - 10.10 | 9.45 | 8.70 | 8.70 | 8.70 | 8.70 | 8.52 | 3.16 | 3.16 | 3.16 | 9.30 - 10.10 | 9.30 - 10.10 | 9.30 - 10.10 | 9.30 - 10.10 | 9.30 - 10.45 | 9.30 - 10.45 |

configure

|

| 3.60 | 4.00 | 4.00 | 3.80 | 3.80 | 3.80 | 3.80 | 3.80 | 3.70 | 3.70 | 3.70 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 |

configure

|

|

| No. of discs | 10 | 12 | 12 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 12 | 12 |

configure

|

| No. of top hats | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 2 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

configure

|

| Input power (kW/hp) | 88 / 120 | 100 / 140 | 145 / 200 | 110 / 150 | 125 / 170 | 110 / 150 | 125 / 170 | 150 / 110 | 170 / 125 | 150 / 110 | 170 / 125 | 130 / 180 | 145 / 200 | 130 / 180 | 145 / 200 | 150 / 200 | 150 / 200 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_Freisteller_468x468px_14_c46259e600.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/f/csm_ActiveMow_KRONE_Freisteller_468x468px_90896875ef.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/5/csm_EasyCut_R_468x468px_57ba0a365d.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/c/csm_EasyCutTS_TC_Freisteller-02_468x468px17_e254895969.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/1/csm_EasyCutB_Freisteller_468x468px13_dcaf1d42a4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/b/csm_EasyCut_F_Highland_468x468px_13a01ebe6c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/3/d/csm_Vendro_Freisteller_468x468px34_cae6bbd02e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/2/csm_KWT_Freisteller_468x468px_e143fd1b3e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/c/csm_Freisteller_Highland_Vendro_468x468px_3d3deddc5c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_Freisteller_Highland_Swadro_468x468px_e4de84fa0f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/4/csm_Bellima_KRONE_Freisteller_468x468px3_1b2baf5141.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/6/f/csm_Fortima_Freisteller_468x468px20_62bb2513c4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/1/csm_Comprima_Freisteller_468x468px11_f9daee659a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/2/csm_Comprima_Plus_Freisteller_468x468px12_3fc2796f9a.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/4/csm_VariPack_Freisteller_f4bfc269dd.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/2/csm_VariPackPlus_Freisteller_468x468px33_142df8329b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/d/csm_EasyWrap150_Freisteller_468x468px18_ee82a0e7eb.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/2/csm_EasyWrap165T_Freistellern_468x468px19_34801004fa.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/0/csm_BiGPack_KRONE_Freisteller_468x468px_0850ee1d84.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/e/0/csm_BiGPack_5-Generation_Freisteller_468x468px8_a813ec6a9f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/b/csm_Bale_Collect_468x468px_eaea52b993.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_Premos5000-Freisteller_468x468px27_86749ba5d4.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/c/csm_MX_Freisteller_468x468px26_6be6e9aee6.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/f/csm_TX_Freisteller_468x468px_49a9760536.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/3/csm_GX_Freisteller_468x468px21_24b0cbfe61.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/c/5/csm_BiGX680_Freisteller_468x468px10_c77559da75.png)